United draining system for effectively lowering seepage lines in fill dam of tailing reservoir

A technology for tailings ponds and accumulation dams, which is applied in the field of seepage drainage systems, and can solve the problems that the effects of seepage drainage and precipitation facilities are not obvious.

Inactive Publication Date: 2011-05-04

SINOSTEEL MAANSHAN INST OF MINING RES

View PDF4 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

While the fine-grained tailings accumulation dam body has an average permeability coefficient of 10 -5 ~10 -6 cm / s, the effect of using common drainage and precipitation facilities is not obvious

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

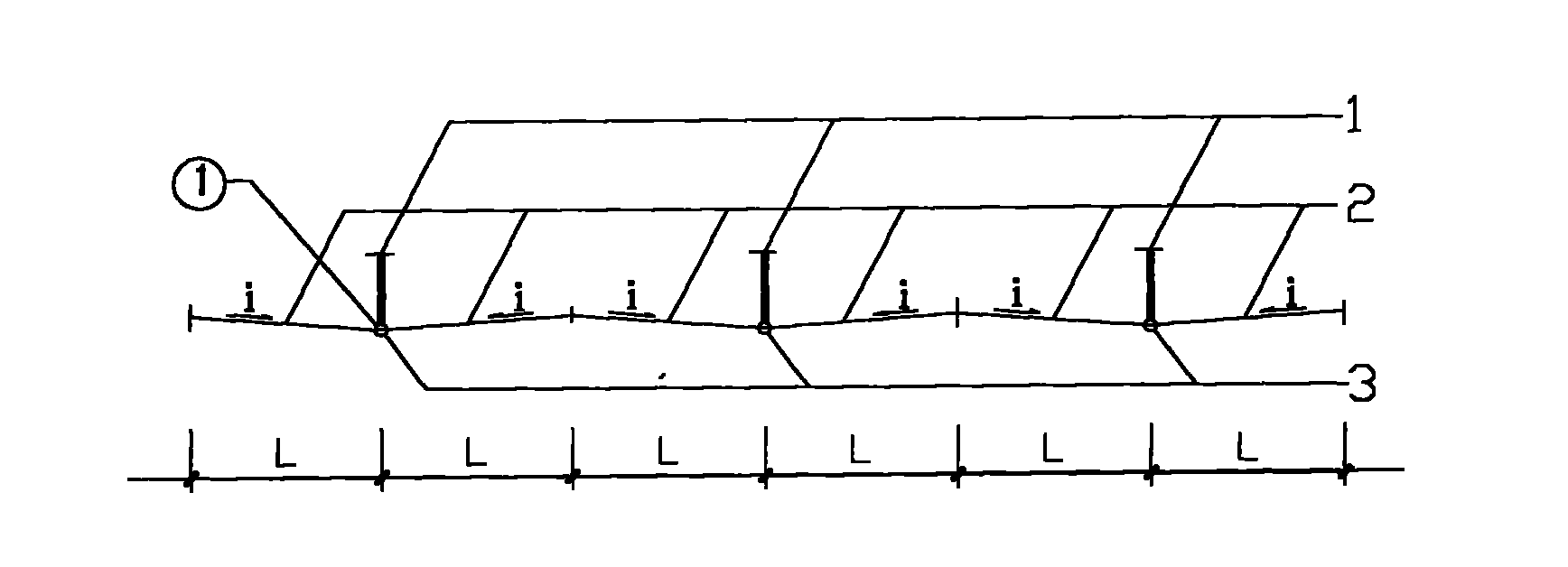

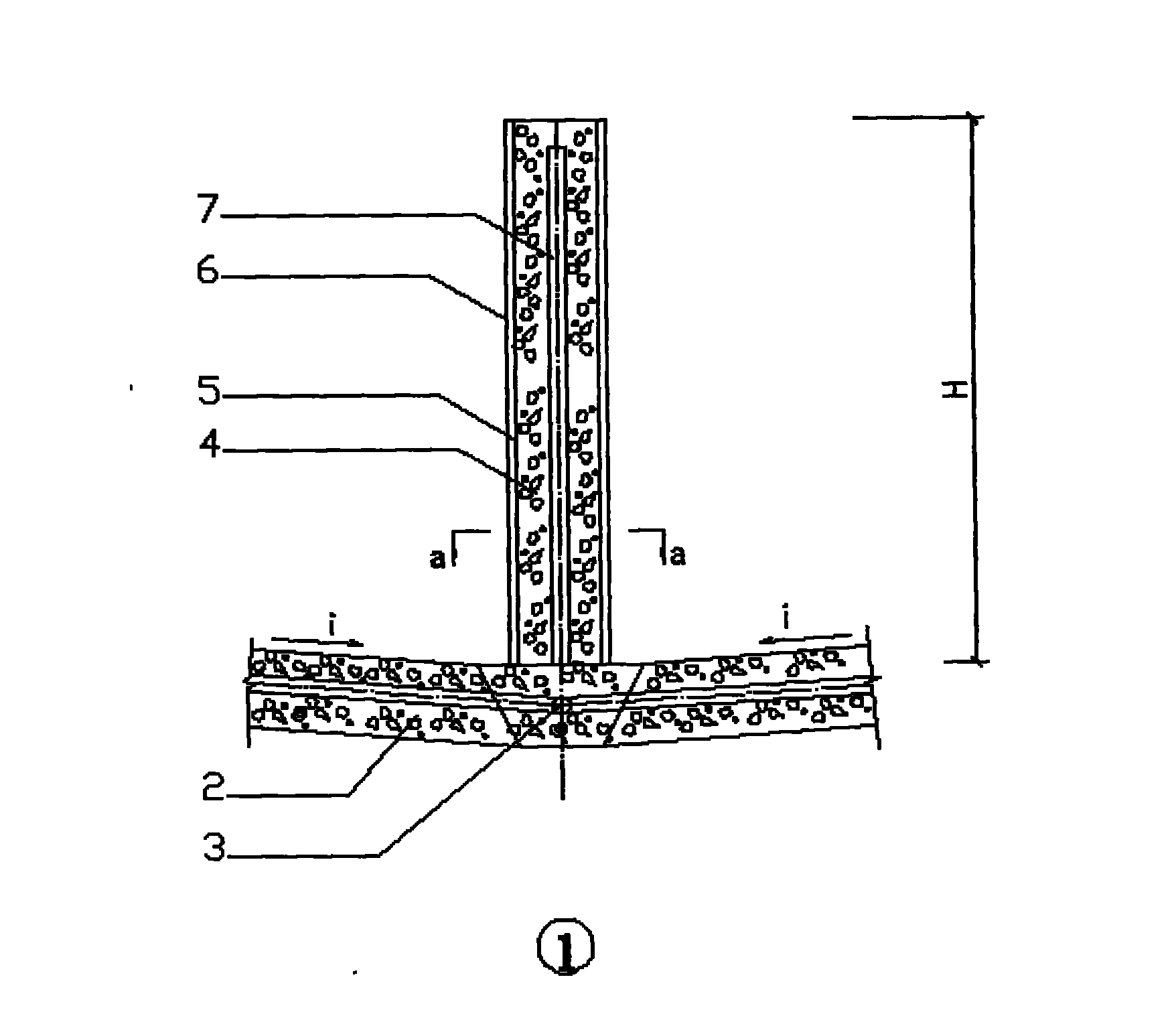

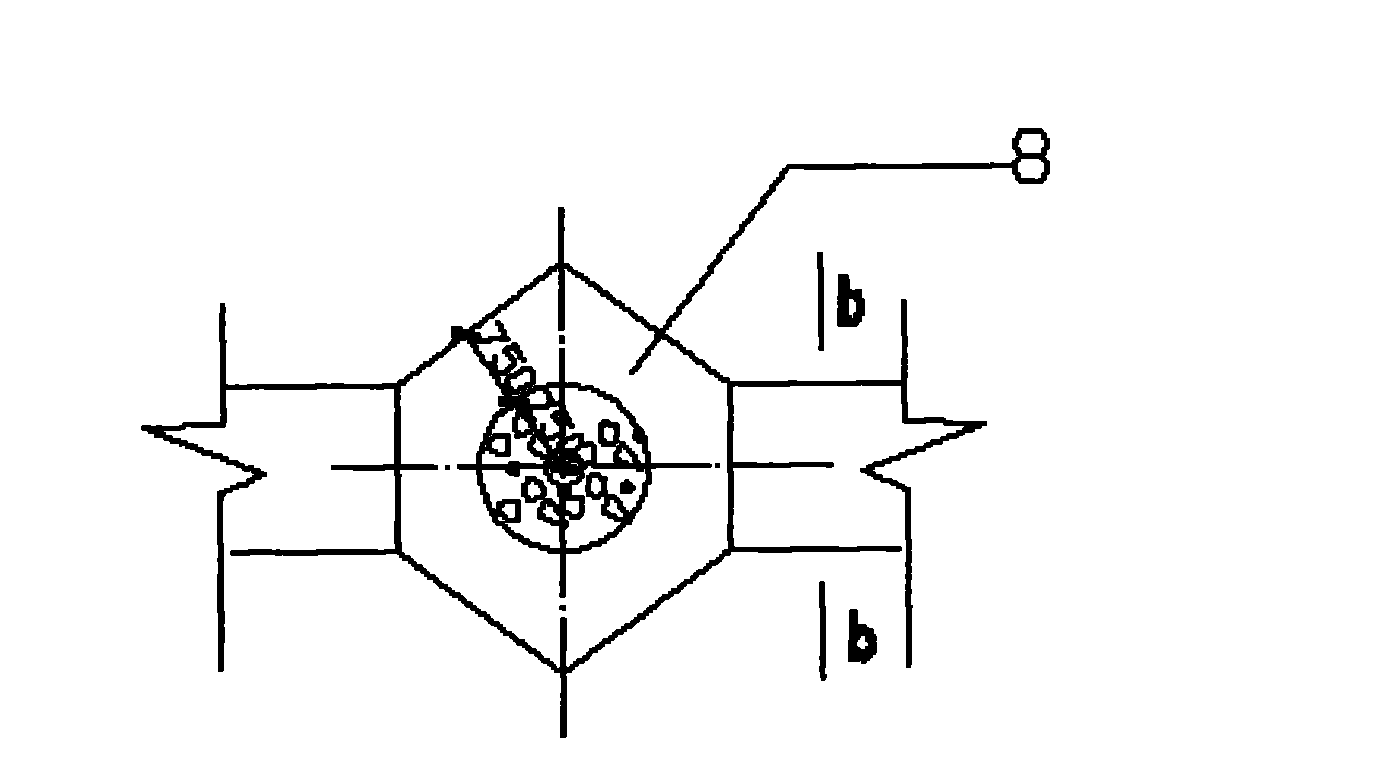

[0021] In order to further describe the present invention, a combined seepage drainage system of the present invention that effectively reduces the seepage line of the accumulation dam of the tailings dam will be further described in detail below in conjunction with the accompanying drawings and examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a united draining system for effectively lowering seepage lines in a fill dam of a tailing reservoir, which comprises vertical draining wells, transverse draining blind ditches (2) parallel to a dam axis, as well as longitudinal draining pipes (3) perpendicular to the dam axis, wherein the transverse draining blind ditches (2) are provided with inversely trapezoidal sections, which are excavated on a tailings-deposited beach face away from a dam top by the designed distance are parallel to the dam axis, and sand gravels (4) are filled in the transverse draining blind ditches (2) after geotextile (4) is laid; the vertical draining wells are arranged at interval along the transverse draining blind ditches (2) , skeletons woven from bamboos or reinforcing mattresses or other materials with similar functions are externally wrapped with the geotextile (6) and internally filled with the sand gravels (4); and the joints of the vertical draining wells and the transverse draining blind ditches are connected to draining open ditches on a dam slope by the longitudinal draining pipes (3). A combined whole capable of draining through automatic flow is formed by adopting three-direction united drainage so that the united draining system can effectively lowers the seepage lines in the fill dam and ensure the safe running of the tailing dam.

Description

technical field [0001] The invention relates to a seepage drainage system for a post-stage accumulation dam of a tailings pond, in particular to a combined seepage drainage system for effectively reducing the seepage line of the accumulation dam of a tailings pond. It is suitable for seepage drainage of all kinds of mine tailings dams built by upstream method, so as to quickly reduce the infiltration line in the accumulation dam body and ensure the safe operation of tailings dams. Background technique [0002] At present, my country's tailings reserves exceed 10 billion tons, and 800 to 1 billion tons of tailings are added every year. Most of the tailings generated during mine production and processing are discharged into tailings storage. Tailings ponds are one of the major hazards. According to the statistics of more than 2,500 large-scale tailing ponds in my country, there have been more than 200 debris flows and dam failures since the 1980s, especially the "9.8" tailing...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E03F1/00E03F5/00

Inventor 代永新周敏刁虎卢敬标徐启明宋光清赵蒙生赵武鹍

Owner SINOSTEEL MAANSHAN INST OF MINING RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com