Knee prosthesis

A knee joint prosthesis and a knee joint technology are applied in the field of knee joint prostheses, which can solve the problems of lack of guiding structure and inability to control joint movement in a normal mode, and achieve the effect of convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

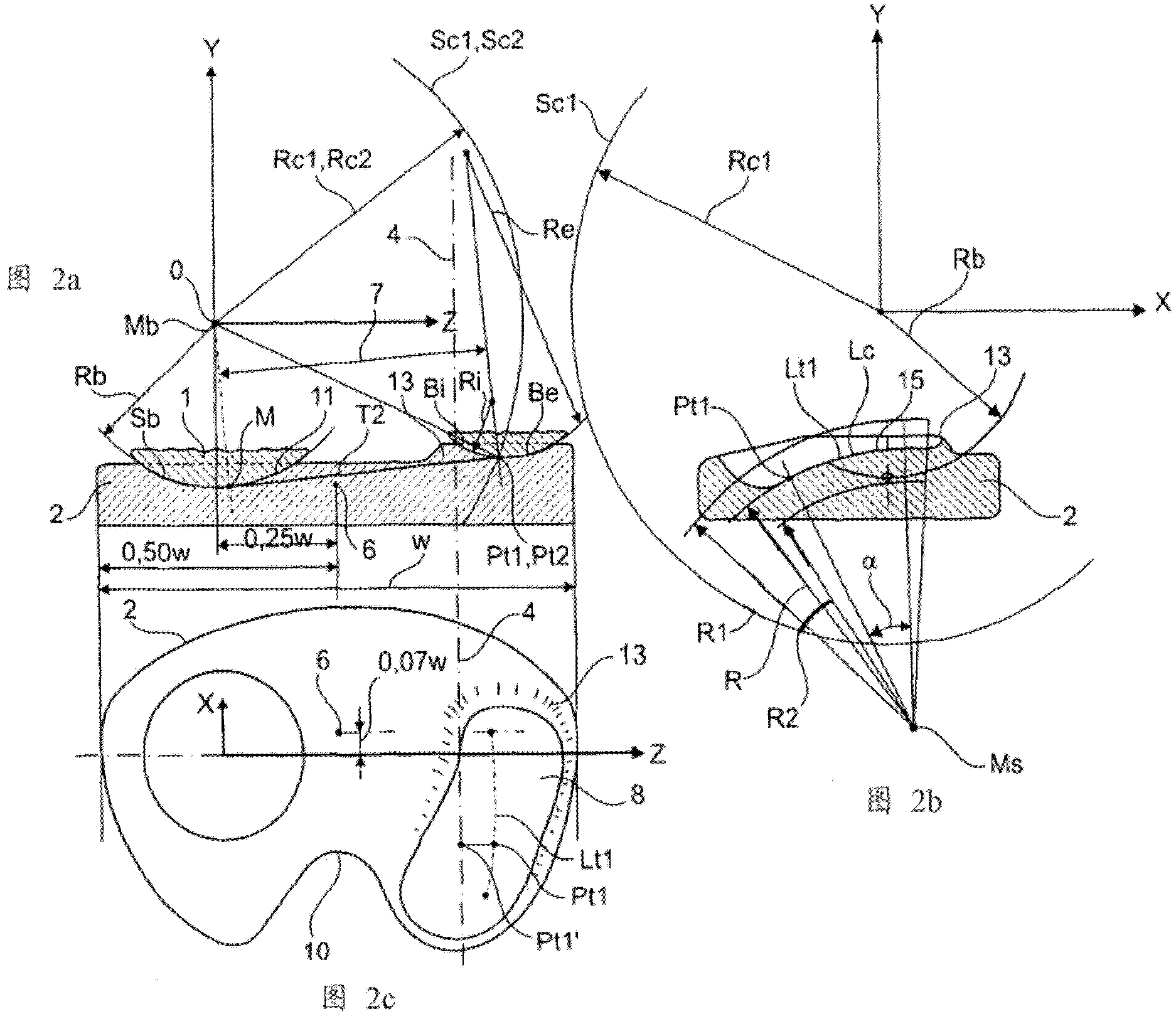

[0079] --refer to Figure 9 with Figure 10 , the radii Re and Ri can be made larger. As the flexion angle increases, the envelope of slack moves from anterior to posterior. With more slack in the middle of the flexion movement and less slack (more stability) at small and large flexion angles, the width of the envelope of slack changes accordingly.

[0080] --refer to Image 6 In the example shown, in the middle of the flexion movement, the guide curves Be and Bi may undergo a slight shift in the direction of the tangent T2 in the plane E1; the spherical radius Rc of the outer guide curve Be is larger and the spherical radius Rc of the inner guide curve Bi is smaller . If a third straight line segment is added between the two guide curves, then as the slack increases, the joint may just fall on the third line segment without joining the two guide curves.

[0081] If the material used is sufficiently elastic, the trajectory line Lt1 or the third line segment can be deflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com