Coaxial through-silicon via

A technology of through-silicon vias and substrates, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve problems such as inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The accompanying drawings, which are incorporated in and constitute a part of this specification, illustrate the presently preferred embodiments of the invention and together with the general description given below and the detailed description of the preferred embodiments given below serve to explain the principles of the invention.

[0031] It should be understood that, for simplicity and clarity of illustration, elements shown in the figures have not necessarily been drawn to scale. For example, the dimensions of some of the elements may be exaggerated relative to other elements for clarity.

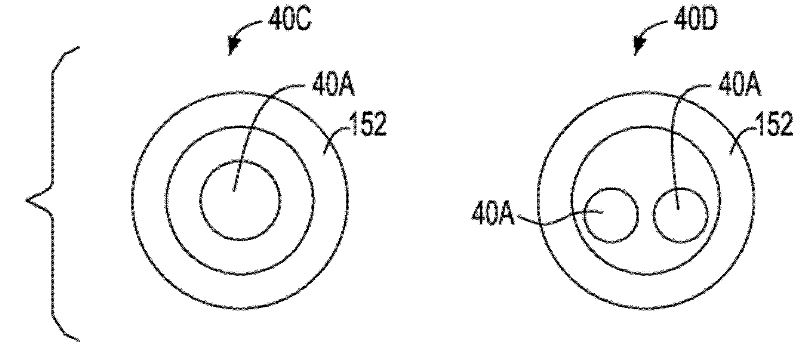

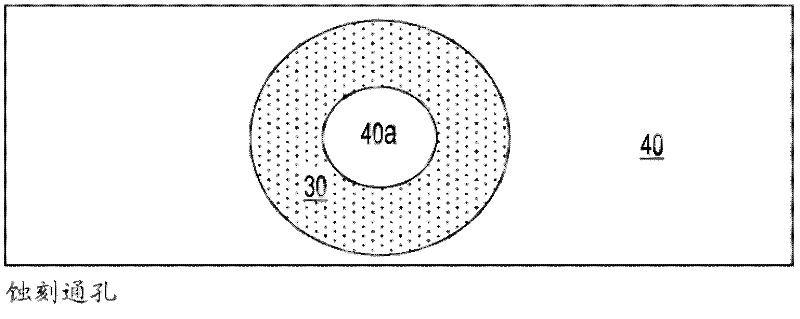

[0032] figure 2 A top view of an annular via 30 etched in a silicon substrate 40 is shown. For the sake of clarity, the structured active layer 45 is not shown in the plan view. The structure is provided with a central pillar 40a defined by etching, made of the same material as the substrate. The width of the central pillar is of the order of 6 μm.

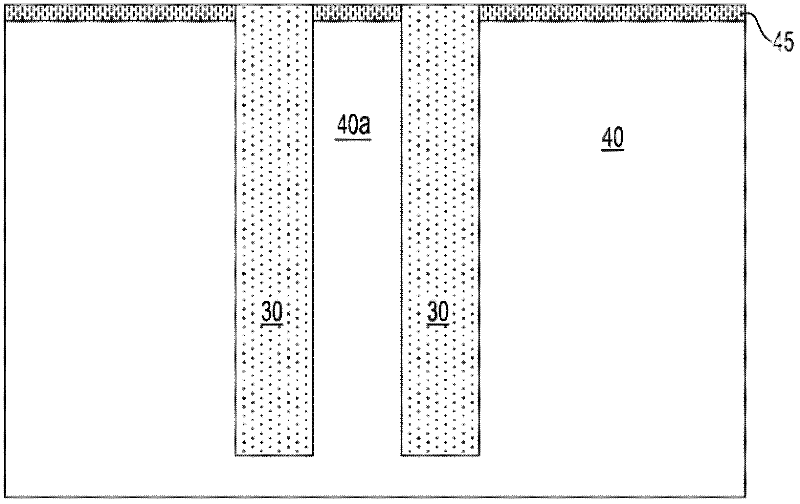

[0033] image 3 yes f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com