Double-acting tapered wedge forming mechanism

A molding mechanism, double-acting technology, applied in molding tools, metal processing equipment, manufacturing tools, etc., can solve the problems of high energy consumption and part unit price, low part production efficiency, unstable part size, etc., to reduce energy consumption and The unit price of parts, the improvement of accuracy, the effect of simplifying complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

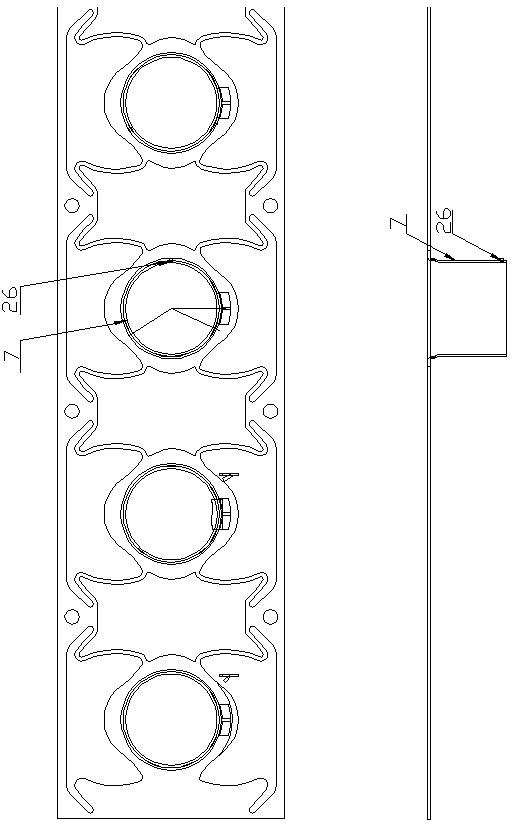

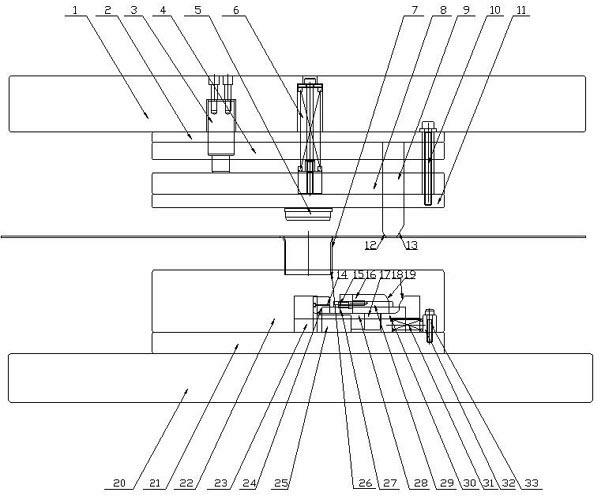

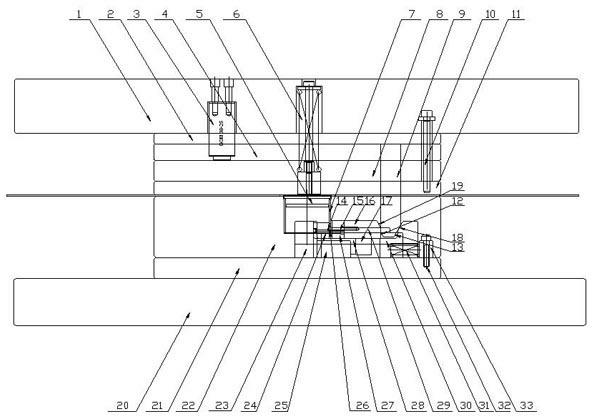

[0030] figure 1 It is a part layout drawing of a product according to an embodiment of the present invention; figure 2 It is a side view of an embodiment of the present invention in a mold-opening state; image 3 It is a side view of an embodiment of the present invention in a closed mold state; Figure 4 It is a partially enlarged top view of an embodiment of the present invention; Figure 5 It is a partially enlarged partial side view of an embodiment of the present invention.

[0031] Such as Figure 1-Figure 5 Shown: double-acting wedge forming mechanism, including upper and lower molds set up and down correspondingly, the upper mold includes upper mold base 1, upper backing plate 2, splint 4, stopper plate 8 and ejector set from top to bottom The material plate 11, and the lower mold includes a lower mold base 20, a lower backi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com