Tensioner of binding strap type securing device

A binding belt and tensioner technology, which is applied in the direction of load fixing, transportation and packaging, and vehicles used for freight, can solve the problems of loss, insecurity, and falling off, and achieve large bolting force, simple operation, and low weight. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

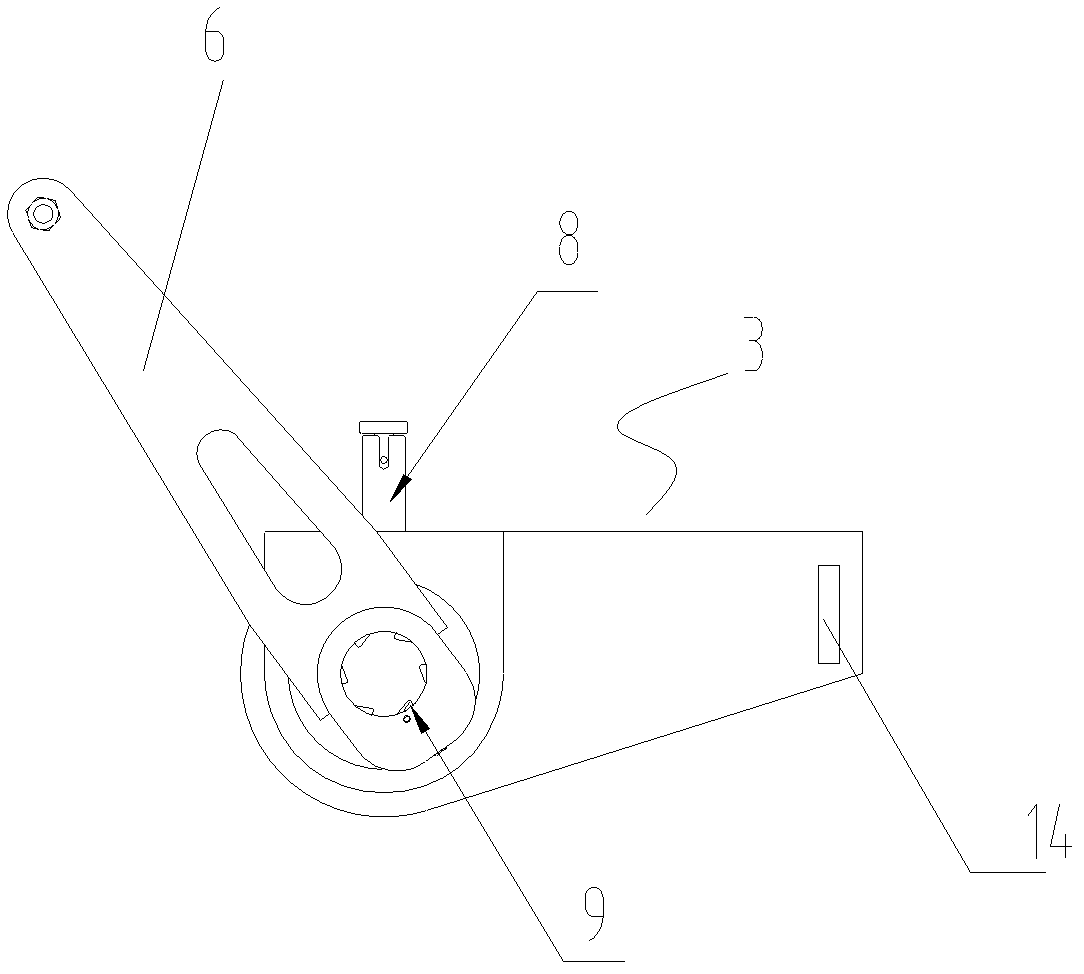

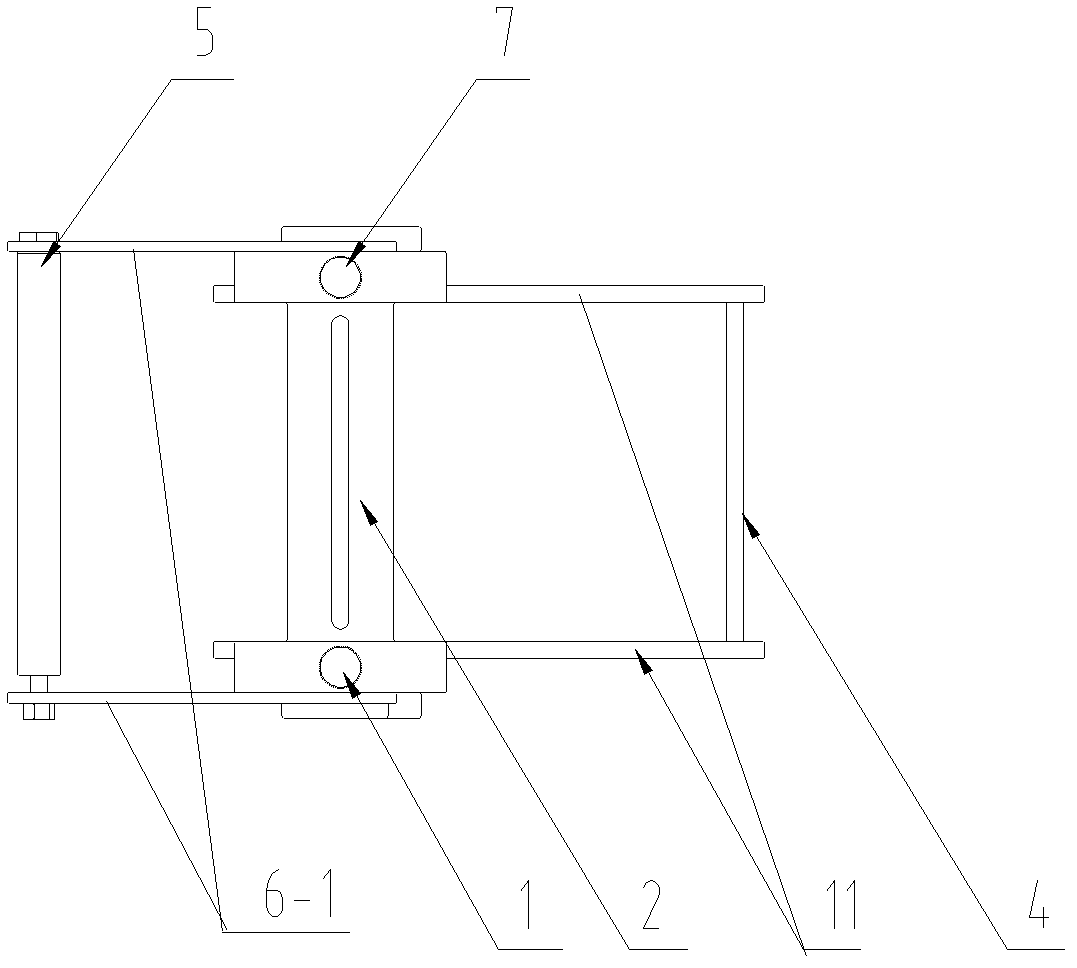

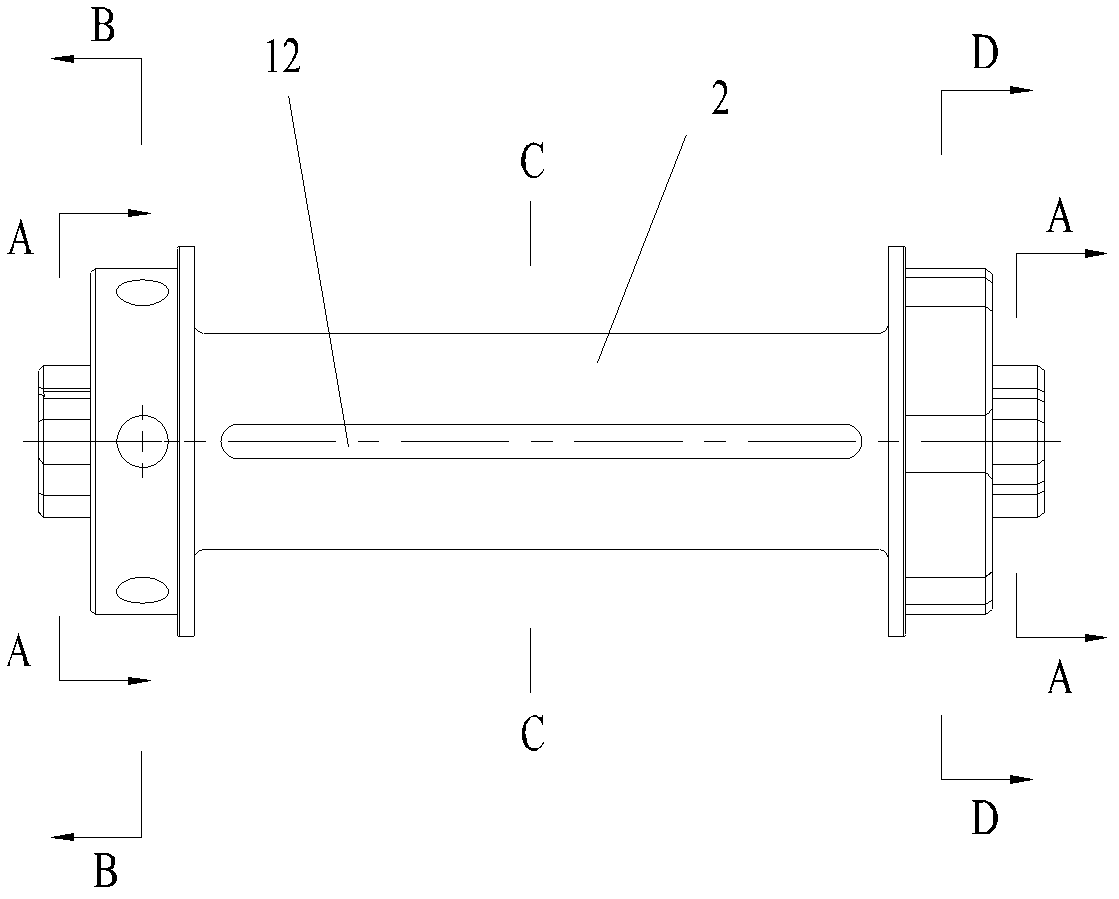

[0016] Below in conjunction with the preferred embodiments, the specific implementation methods provided according to the present invention are described in detail as follows: See the accompanying drawings for details, a tensioner for a strap-type fastening device, including a frame body 3 and a frame tension frame 6, The frame body is mainly composed of the twist belt shaft 2, the shaft sleeve body 10, the left and right side plates 11 and the baffle plate 4, the left and right side plates are respectively welded with the shaft sleeve body as a whole, and the front ends of the left and right side plates are connected with the baffle plate , the shaft sleeve body is supported with a twisted belt shaft, and the twisted belt shaft is provided with a long slot 12 that runs through the binding belt along its longitudinal direction, and the two ends of the twisted belt shaft are slidingly connected with the central round hole of the frame tensioning frame, so Ratchets are provided a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com