Cleaning machine of range hood

A cleaning machine and range hood technology, applied in the direction of removing oil fumes, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as affecting the service life of the range hood, affecting the use effect of the range hood, and incomplete clarity. The effect of long service life, labor-saving and convenient operation, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

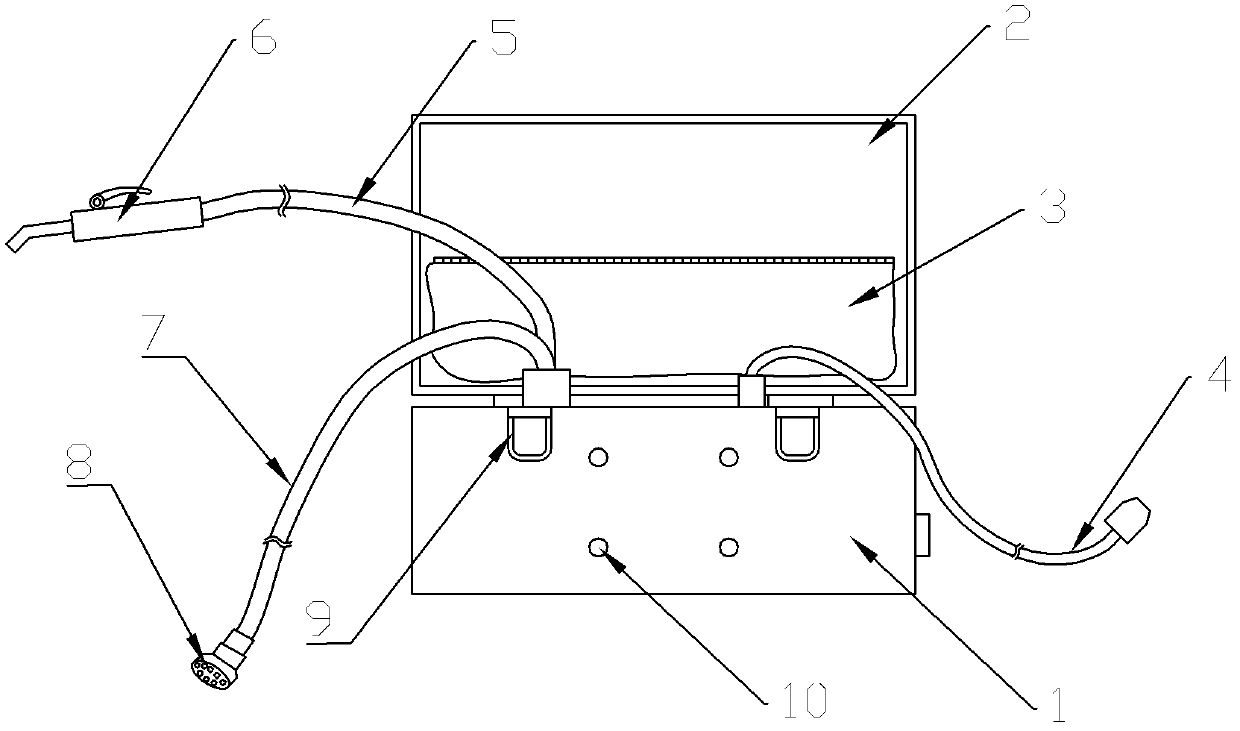

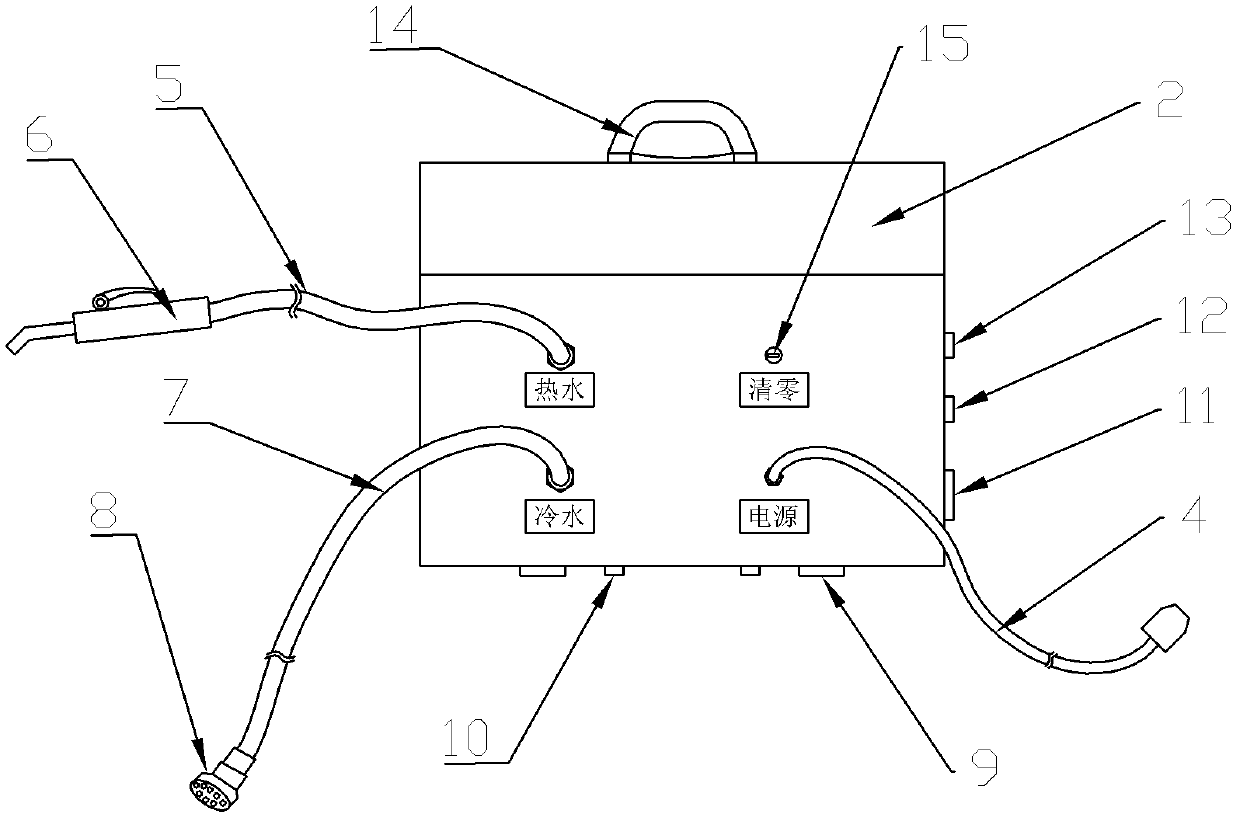

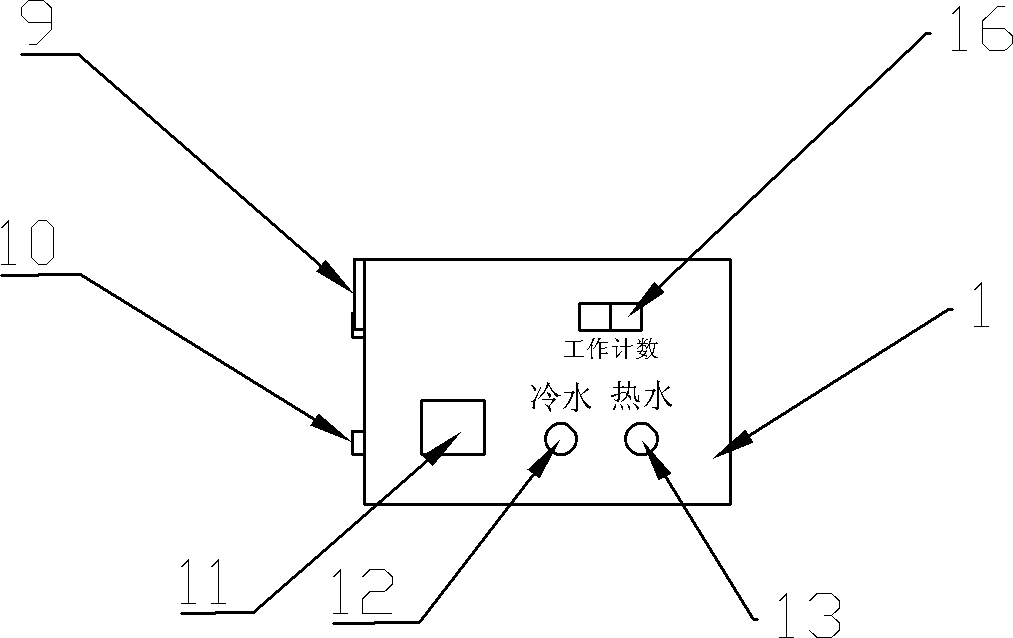

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

[0021] like figure 1 , figure 2 , image 3 shown. The range hood cleaning machine includes a machine 1. The body 1 is provided with a self-priming pump 17, a heating liner 19 and a control circuit board. The body 1 is provided with a water inlet pipe 7, a water spray pipe 5 and a power cord 4. The water inlet of the self-priming pump 17 is connected to the water inlet pipe 7 , and the water outlet is connected to the heating inner tank 19 , and the heating inner tank 19 communicates with the water spray pipe 5 . The end of the water inlet pipe 7 is provided with a water distributor 8 communicating with it, and through holes are evenly distributed on the end surface of the water distributor 8 . The end of the spray pipe 5 is provided with an adjustable spray gun 6, and a pressure switch 18 is arranged in the spray gun 6. The body 1 is provided with a power switch 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com