Testing method for marginal adaptation of exposure table of exposure machine

A test method and technology of an exposure table, which is applied in microlithography exposure equipment, photolithography exposure equipment, liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of negligible, general, single monitoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

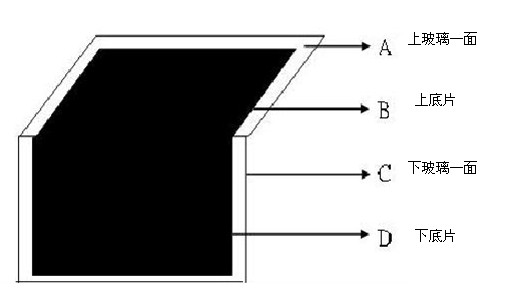

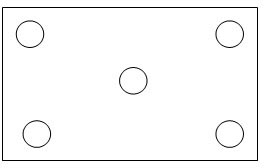

[0016] Install a blank film whose length and width are 0-1 inch smaller than the exposure table on the exposure table, absorb 1 drop of colorless water on the four corners and the middle of the upper film, as attached figure 2 As shown, the position of the drop of liquid at the four corners is 4 cm away from the edge of the film, the frame is closed and sucked into a vacuum, and the diffusion of the water film is observed. The test results are shown in the attached Figure 5 As shown, it can be judged that the tightness of the exposure table is better.

specific Embodiment 2

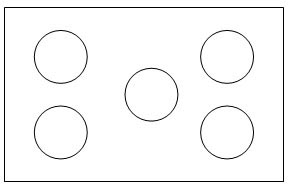

[0017] Install a blank film whose length and width are 0-1 inches smaller than the exposure table on the exposure table, absorb 1 drop of red alcohol on the four corners and the middle of the lower film, as attached image 3 As shown, the position where the alcohol drops at the four corners is 5 cm away from the edge of the negative film, the frame is closed and sucked into a vacuum, and the diffusion of the alcohol film is observed. The test results are shown in the attached Image 6 As shown, it can be judged that the tightness of the exposure table is not good.

specific Embodiment 3

[0018] Install a blank film whose length and width are 0-1 inch smaller than the exposure table on the exposure table, absorb 5 drops of green water on the four corners and the middle of the upper film, as attached Figure 4 As shown, the dripping position at the four corners is 10 cm away from the edge of the film, the frame is closed and sucked into a vacuum, and the diffusion of the water film is observed. The test results are shown in the attached Figure 7 As shown, it can be judged that the tightness of the exposure table is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com