Method for testing critical energy of detonation formed by direct initiation

A technology of critical energy and test method, applied in the direction of material explosiveness, etc., can solve the problem of test system without direct detonation critical energy, and achieve the effect of reducing the harm of life safety and property loss, easy operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

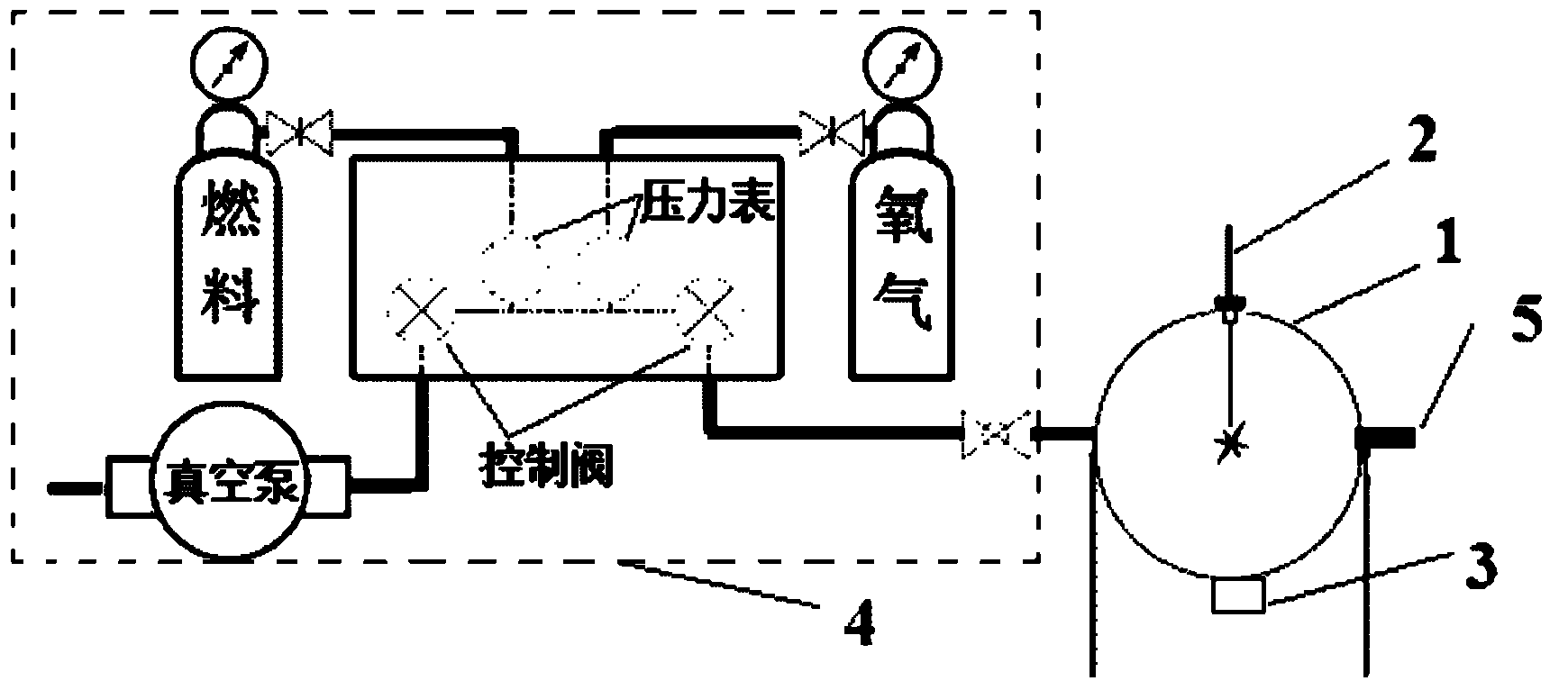

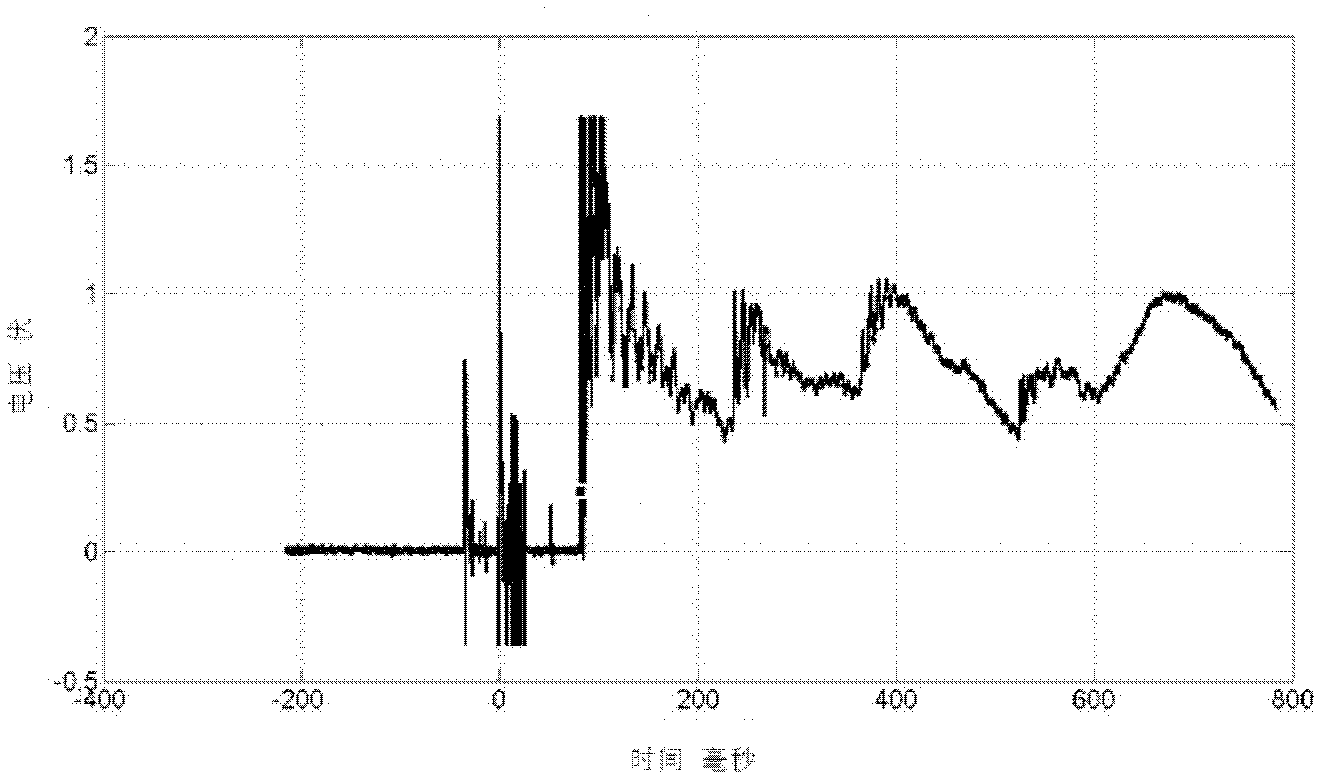

[0020] See attached figure 1 , 2, a kind of critical energy test method that direct detonation forms detonation, it uses a kind of critical energy test system that direct detonation forms detonation, and the critical energy test system that described direct detonation forms detonation comprises: initiation device 1, oscilloscope and ignition circuit;

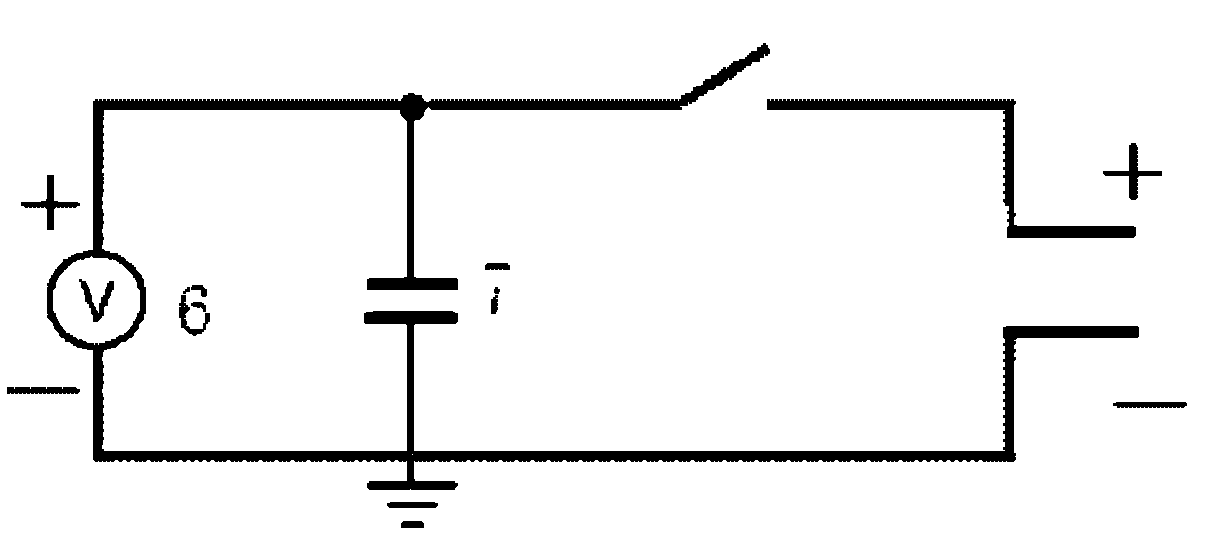

[0021] The detonating device 1 is a spherical container with an internal diameter of 200 mm, a wall thickness of 50 mm, and a maximum pressure of 100 MPa. An ignition rod 2 is arranged on the top thereof, and the cross section of the ignition head of the ignition rod 2 is a circle with a radius of 3.5 mm. The positive pole is located at the center of the circle, and a layer of insulating ceramics is wrapped between the negative pole and the positive pole; a heating belt 3 is provided at the bottom, and a control panel 4 is connected to one side of the control panel 4. One end of the control panel 4 is provided with the detonatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Maximum pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com