Testing device for dynamic venting quality of safety airbag fabric and method thereof

A technology for airbags and testing devices, applied in the direction of analyzing materials, instruments, etc., can solve the problems of unsuitable testing instruments, high price of shock tubes, and large device footprint, and achieve the effects of small size, accurate measurement, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

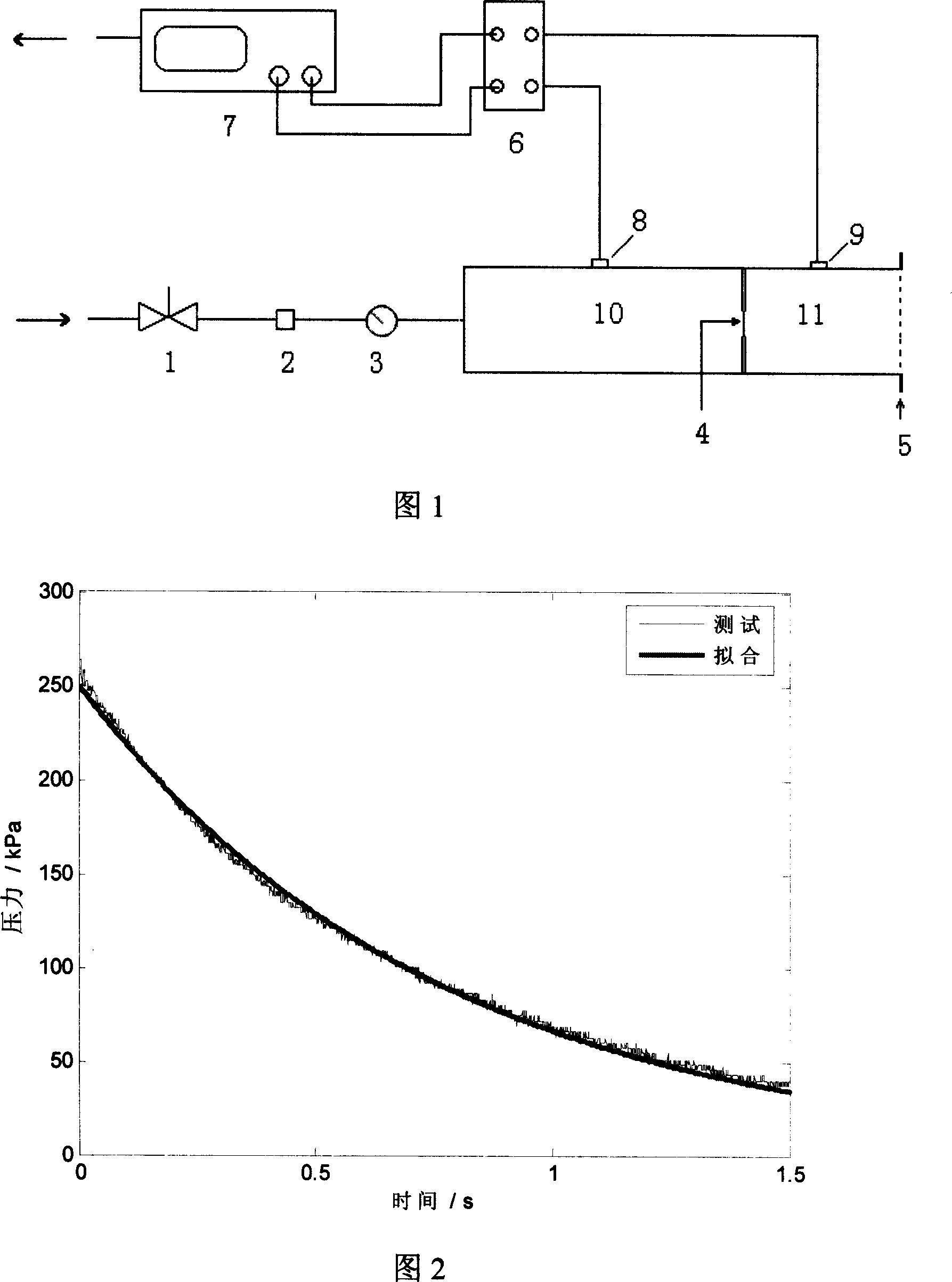

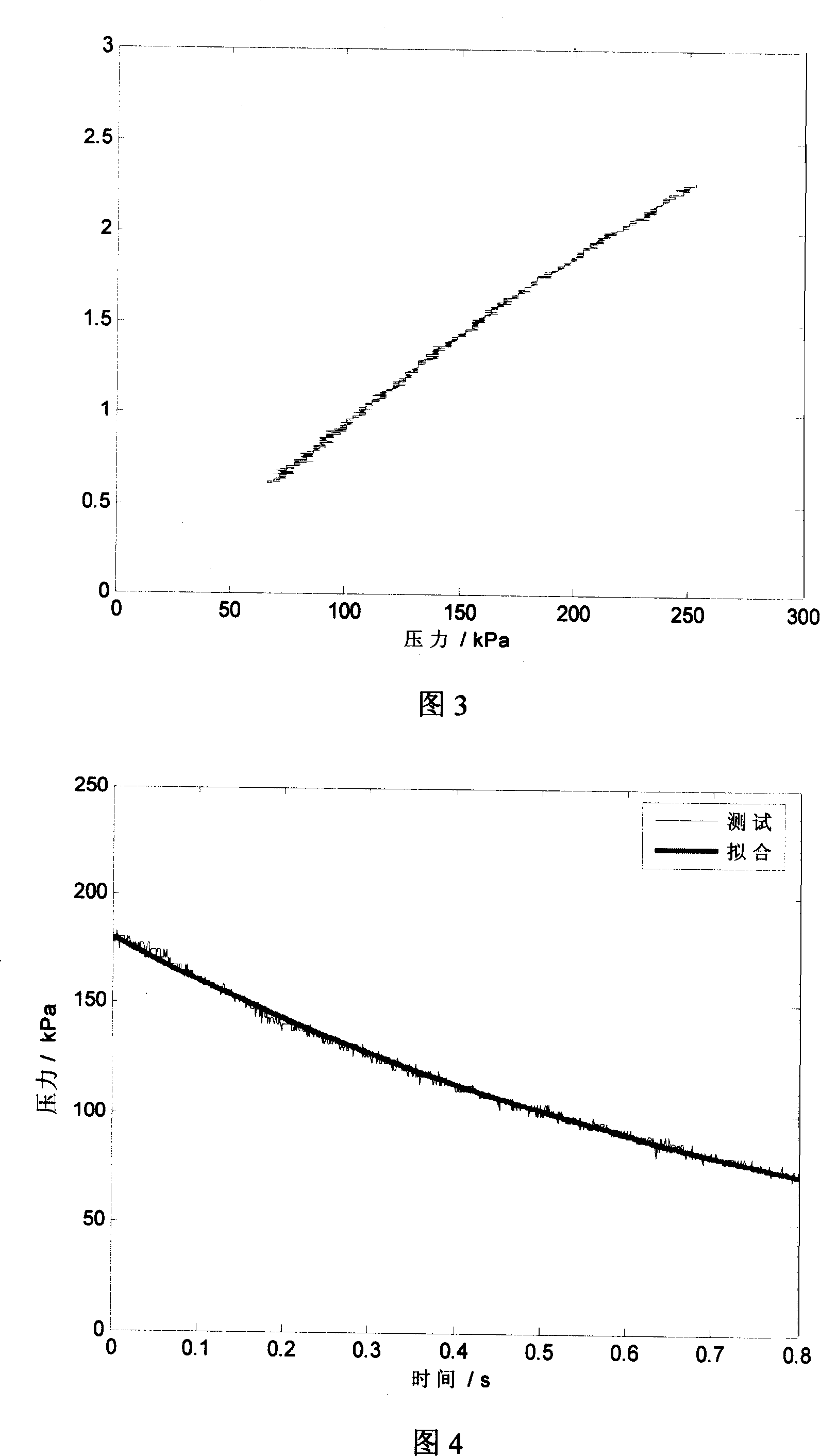

[0047]During the test, the atmospheric temperature was 25°C and the atmospheric pressure was 100kPa. Sample A is nylon 66 plain weave airbag fabric 5, the filament fineness is 350 / 73dtex / f, and the warp and weft density of the fabric is 250×238 threads / 10cm. Make the fabric A to be tested into the required pattern size and fix it at the end of the device. The hole diameter of the selected orifice plate is 3 cm, and the thickness of the film 4 is 15 microns. Fix the orifice plate and film according to the installation requirements. Set the parameters of oscilloscope 7 and coupler 6. When starting the test, open the valve 1 and adjust the trim 2 so that the gas from the air compressor enters the high-pressure air chamber 10 slowly. After the membrane bursts, close the valve.

[0048] The pressure sensor 9 collects the pressure values at different times in the low-pressure gas chamber, amplifies them through the coupler 6, transmits them to the digital oscilloscope 7, and c...

example 2

[0051] During the test, the atmospheric temperature was 25°C and the atmospheric pressure was 100kPa. Sample B is nylon 66 plain weave airbag fabric 5, the filament fineness is 350 / 73dtex / f, and the warp and weft density of the fabric is 260×256 threads / 10cm. Make the fabric B to be tested into the required pattern size and fix it at the end of the device. The hole diameter of the selected orifice plate is 3 cm, and the thickness of the film 4 is 12 microns. Fix the orifice plate and film according to the installation requirements. Set the parameters of oscilloscope 7 and coupler 6. When starting the test, open the valve 1 and adjust the trim 2 so that the gas from the air compressor enters the high-pressure air chamber 10 slowly. After the membrane bursts, close the valve.

[0052] The pressure sensor 9 collects the pressure values at different times in the low-pressure gas chamber, amplifies them through the coupler 6, transmits them to the digital oscilloscope 7, and ...

example 3

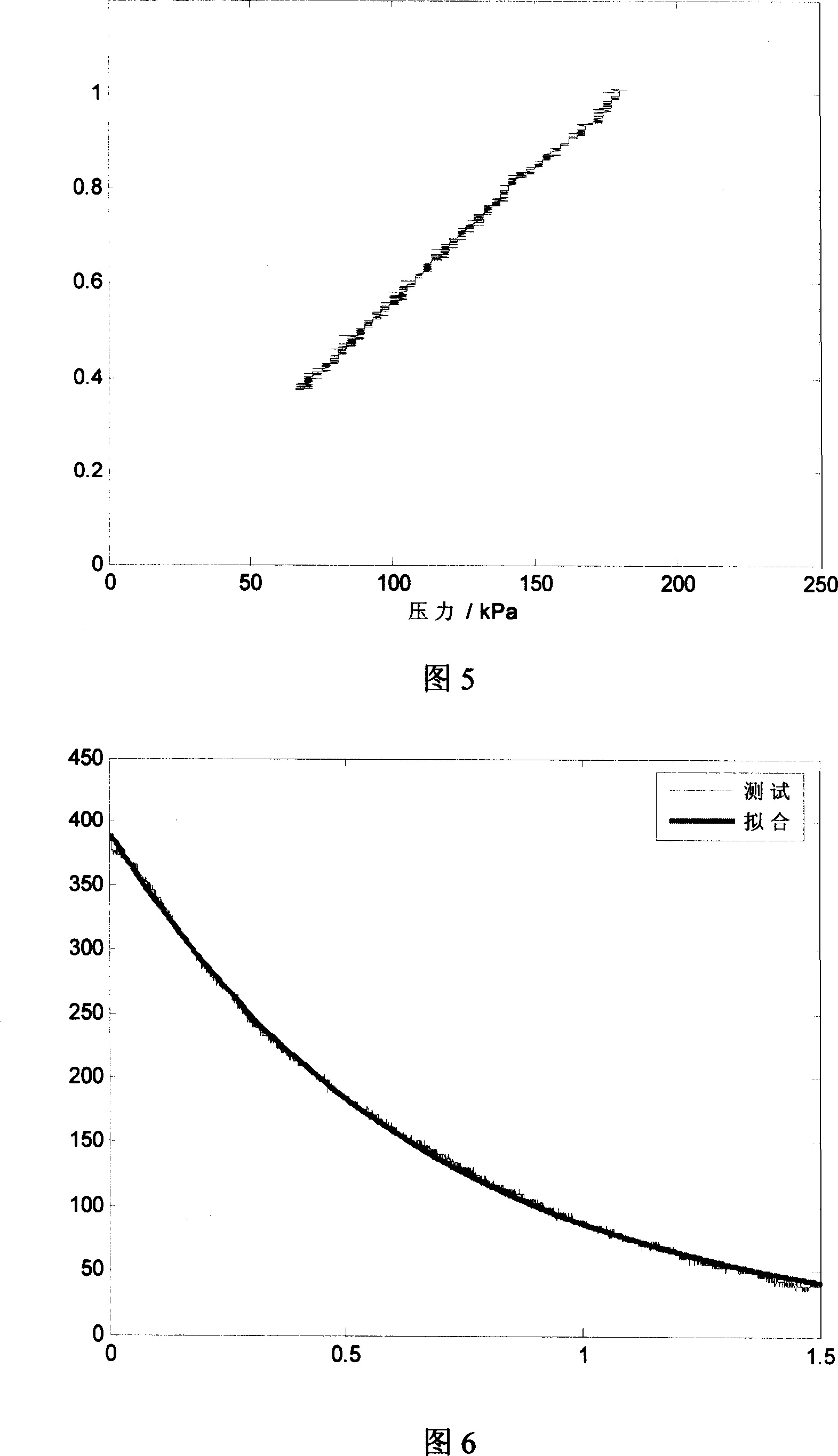

[0055] During the test, the atmospheric temperature was 25°C and the atmospheric pressure was 100kPa. Sample C is nylon 66 plain weave airbag fabric 5, the filament fineness is 479 / 72dtex / f, and the warp and weft density of the fabric is 216.5×216.5 threads / 10cm. Make the fabric C to be tested into the required pattern size and fix it at the end of the device. The hole diameter of the selected orifice plate is 2 cm, and the thickness of the film 4 is 15 microns. Fix the orifice plate and film according to the installation requirements. Set the parameters of oscilloscope 7 and coupler 6. When starting the test, open the valve 1 and adjust the trim 2 so that the gas from the air compressor enters the high-pressure air chamber 10 slowly. After the membrane bursts, close the valve.

[0056] The pressure sensor 9 collects the pressure values at different times in the low-pressure gas chamber, amplifies them through the coupler 6, transmits them to the digital oscilloscope 7, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com