Static simulation test device and static simulation test method for chemical catalytic cracking of thickened oil under assistance of ultrasonic wave

A simulation experiment device and chemical catalysis technology, which is applied in the field of ultrasonic-assisted heavy oil chemical catalytic cracking static simulation experiment device, can solve problems such as being unsuitable for high temperature and high pressure conditions, and achieve the effects of high practical value, convenient installation and layout, and low investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

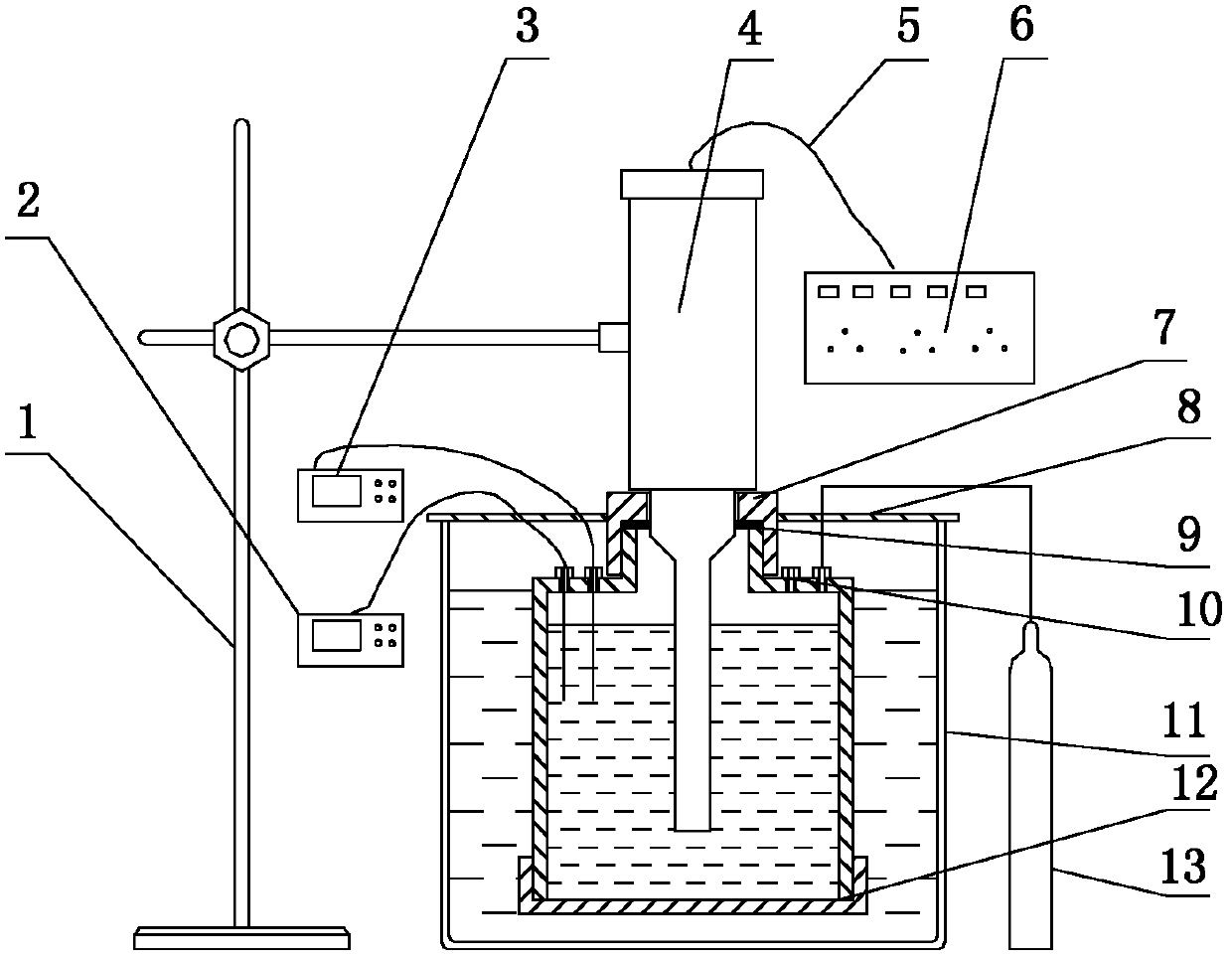

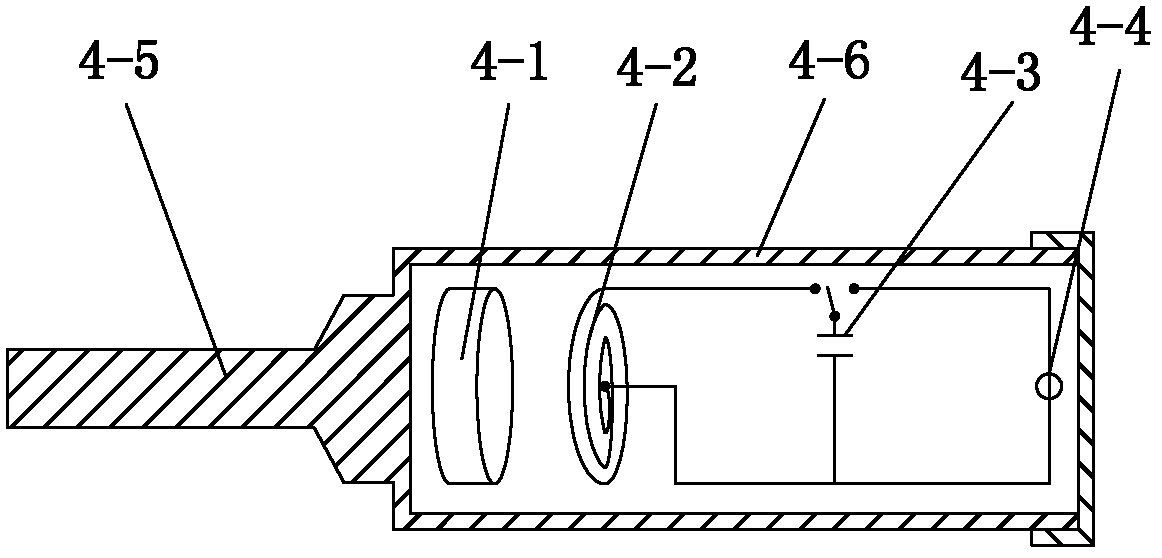

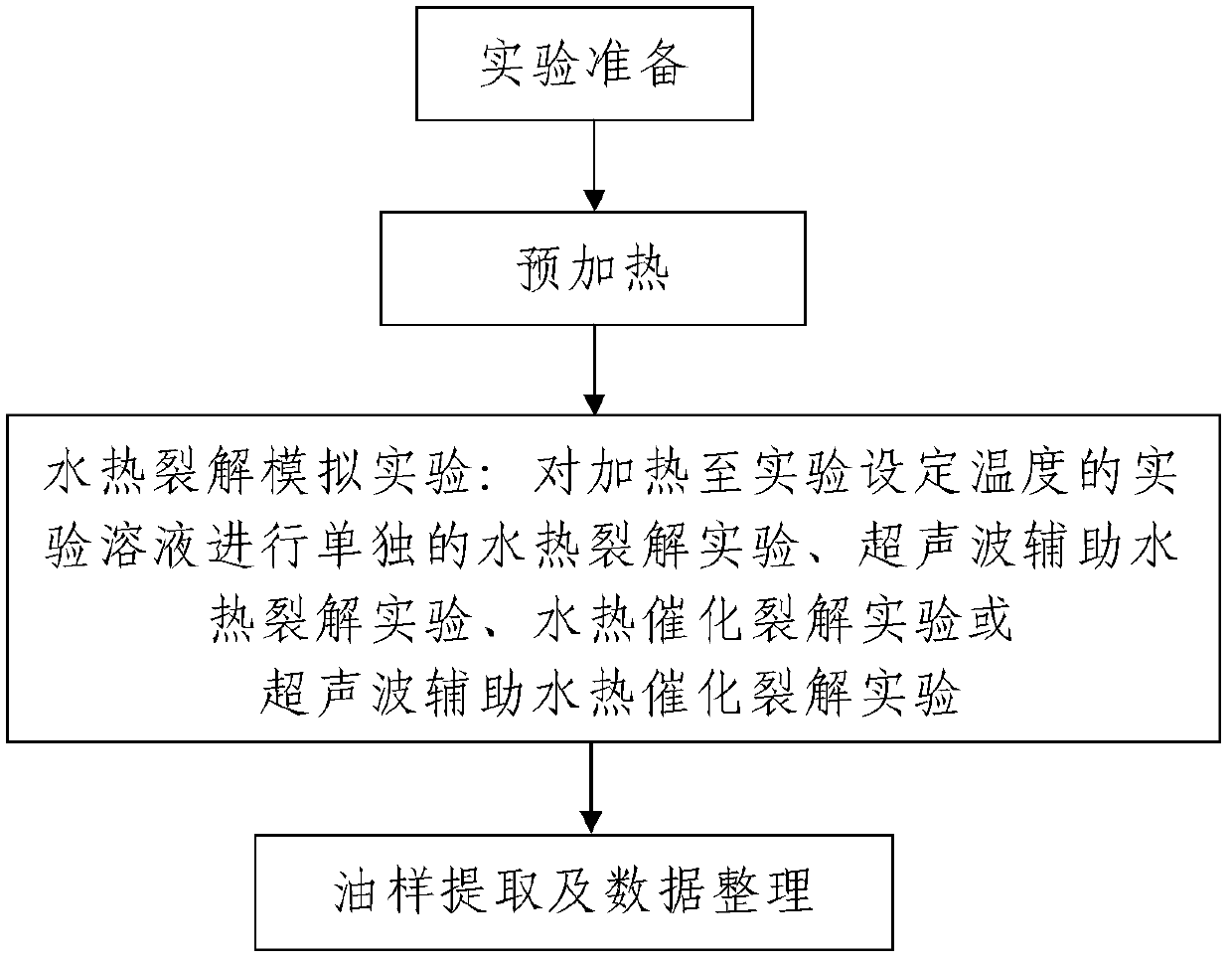

[0051] Such as figure 1 The shown ultrasonic-assisted heavy oil chemical catalytic cracking static simulation experiment device includes a constant temperature heating device, a reaction tank 12 with a test solution inside, and a temperature detection unit for real-time detection of the temperature of the test solution in the reaction tank 12 3. The pressure detection unit 2 for real-time detection of the liquid pressure of the test solution in the reaction tank 12, the ultrasonic transducer 4 for ultrasonic treatment of the test solution in the reaction tank 12 and the ultrasonic transducer 4. The ultrasonic generator 6, the ultrasonic transducer 4 is installed on the reaction tank 12. The reaction tank 12 is connected with the high-pressure nitrogen cylinder 13 through the connecting pipeline and before the experiment, the high-pressure nitrogen cylinder 13 is used to fill the reaction tank 12 with nitrogen to discharge the retained air in the reaction tank 12. The reaction ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap