Seed-coat-removal preventing device for air-blowing type seeding apparatus

A seed metering and air blowing technology, which is applied to the parts of the planter, can solve the problems of the pneumatic planter's poor compliance with the operating rules and other problems, and achieve the effects of simple structure, avoidance of seed knocking, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

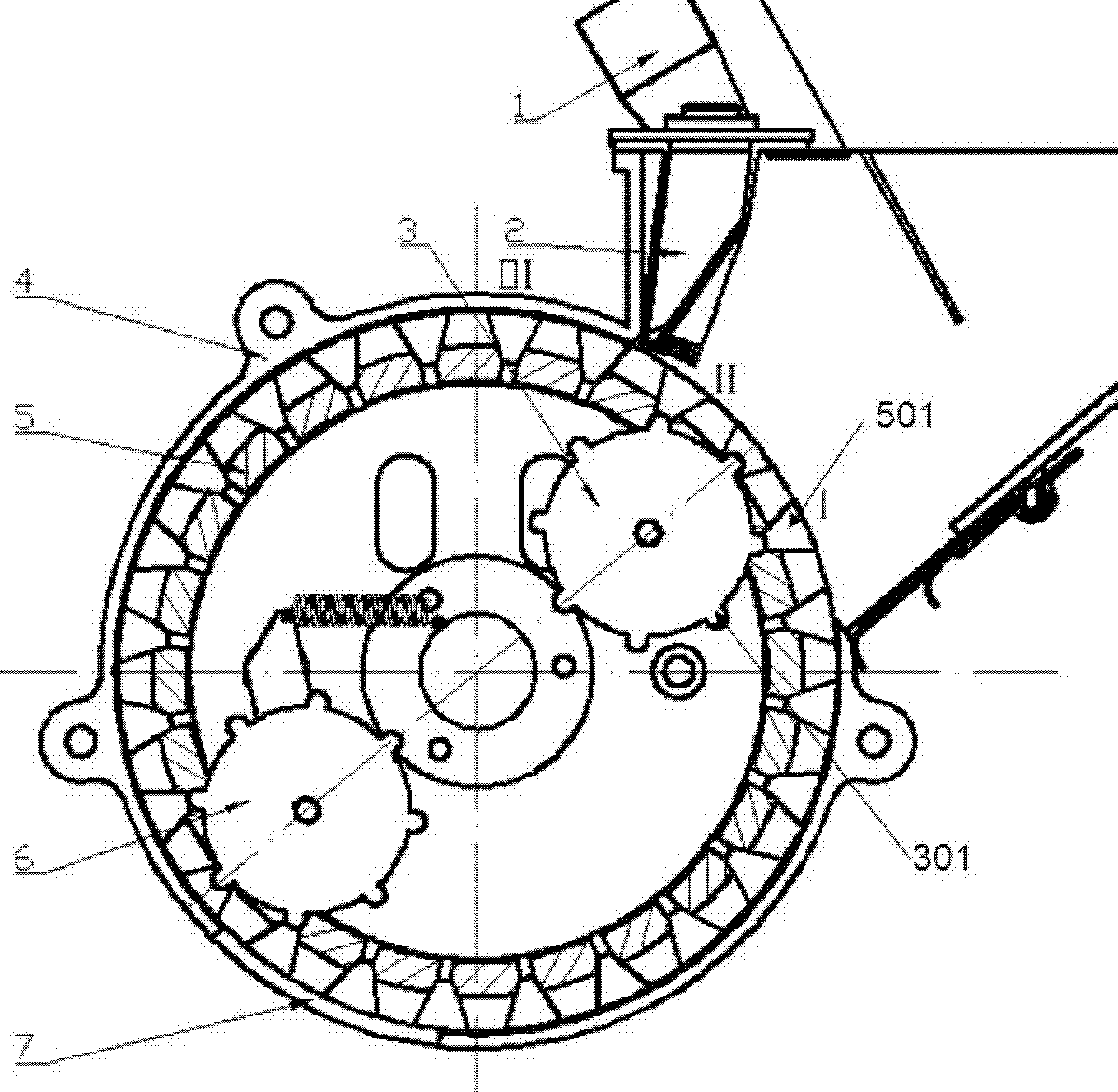

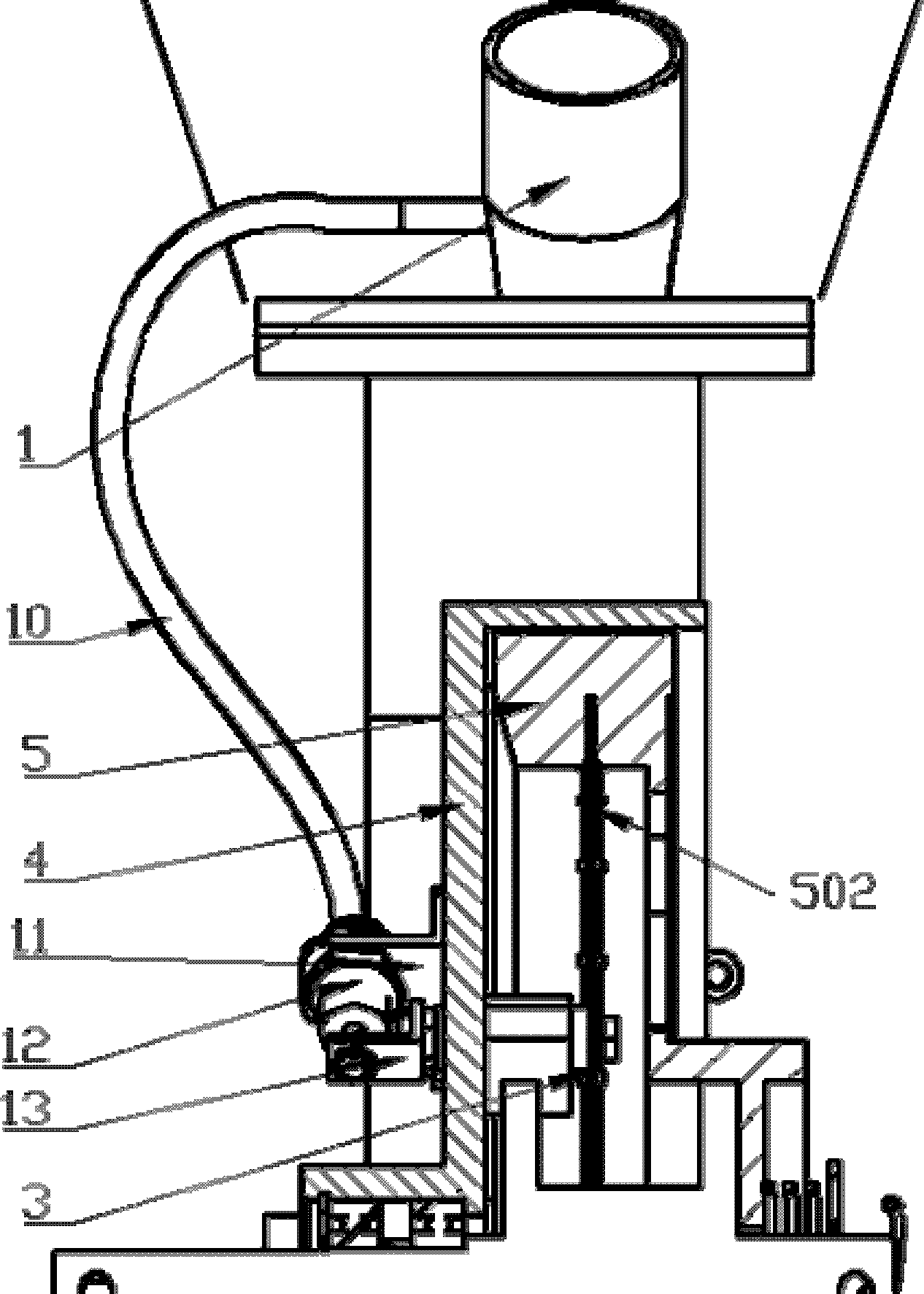

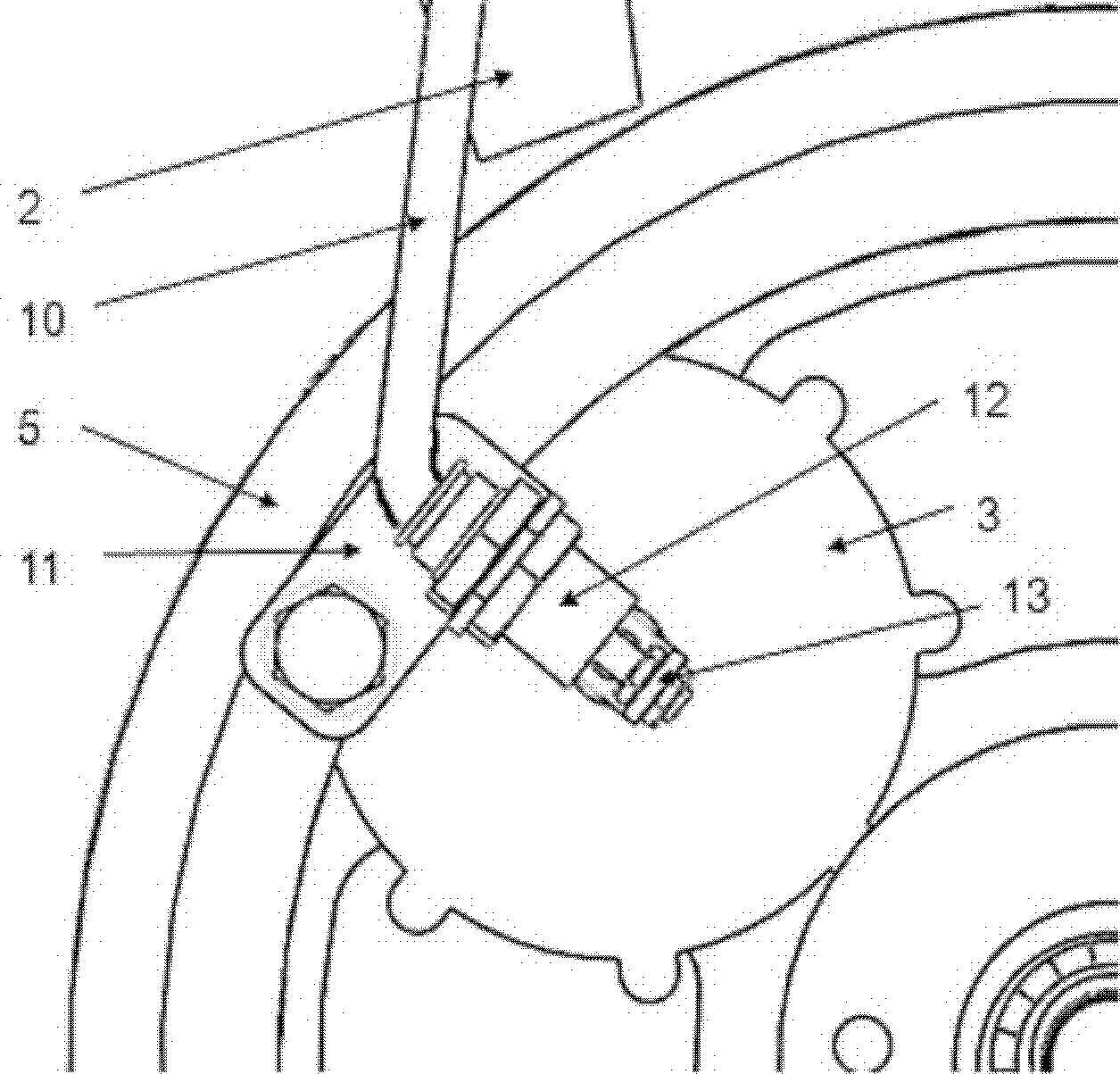

[0047] Such as figure 1 with figure 2 Shown is a front sectional view and a right sectional view of the overall structure of the anti-knock device of Embodiment 1. Wherein, the anti-knocking seed pushing sheet is a circular anti-knocking seed pushing sheet 3 with pushing ears 301 distributed on the circumference, and the pushing part is the pushing ears 301.

[0048] The control mechanism is a needle-type cylinder 12, which is fixed on the lower casing 4 of the seed meter by a cylinder fixing frame 11 through bolts, and the cylinder action point connecting frame 13 extends the cylinder of the needle-type cylinder 12 to a rod 1201 It is connected with the round anti-knocking seed pushing piece 3 to realize the linkage between the needle-shaped cylinder 12 and the circular anti-knocking seed pushing piece 3; The air inlet 1 is connected.

[0049] The anti-knocking device is installed at a certain position before the seed clearing area II, and in the working state, such as ...

Embodiment approach 2

[0053] Such as Figure 5 As shown, it is a perspective view of the working state of the anti-knocking device of the second embodiment. Wherein, the anti-knocking seed pushing sheet is a circular anti-knocking seed pushing sheet 3 with pushing ears 301 distributed on the circumference, and the pushing part is the pushing ears 301.

[0054] The control mechanism is the pusher arm 16, the circular anti-knocking seed pusher 3 is hinged to one end of the pusher arm 16, and the other end of the pusher arm 16 is hinged to the lower housing 4 of the seed meter. and can rotate around point A; the torsion spring 17 is sandwiched between the seed push arm 16 and the torsion spring limit sleeve 18, and pushes the seed push arm 16 toward the outer edge of the seed tray 5 The arm limit sleeve 15 is fixed by the position adjusting bolt 19 of the arm limit sleeve passing through the adjustment hole 14 on the lower housing 4 of the seed meter. One end of the pusher arm 16 abuts against the l...

Embodiment approach 3

[0056] Such as Figure 7 As shown, it is the working state diagram of the anti-knocking device of the third embodiment, Figure 8 for Figure 7 Schematic diagram of the installation position of the middle anti-knocking seed pushing piece on the upper housing, wherein the anti-knocking seed pushing piece is an arc-shaped anti-knocking seed pushing piece 8 with a pushing arc 801, and the pushing part is a pushing arc Tablet 801.

[0057] The control mechanism is a position adjusting nut 9. One end of the arc-shaped anti-knocking seed pushing piece 8 is movably connected to the upper housing 20 of the seed meter through a thread, and the other end is adjustablely connected to the seed meter through the position adjusting nut 9. On the oblong hole of the housing 20, changing the position of the position adjusting nut 9 on the oblong hole of the upper housing 20 of the seed metering device can determine whether the pushing arc 801 of the arc-shaped anti-knocking seed pushing shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com