Cement-based material expansion agent and preparation method thereof

A technology of cement-based materials and expansion agents, which is applied in the field of building materials to achieve the effects of reducing pollution, improving carbonation resistance, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

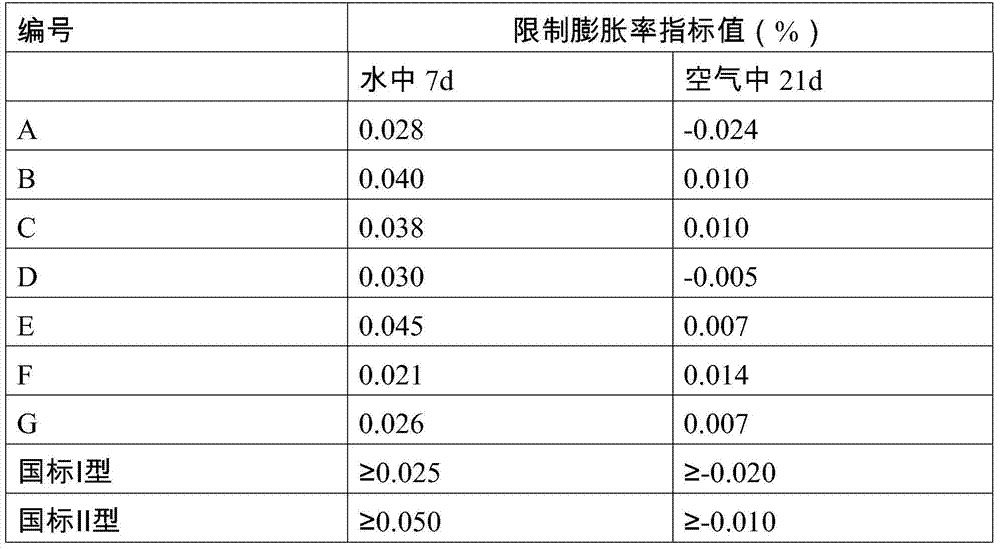

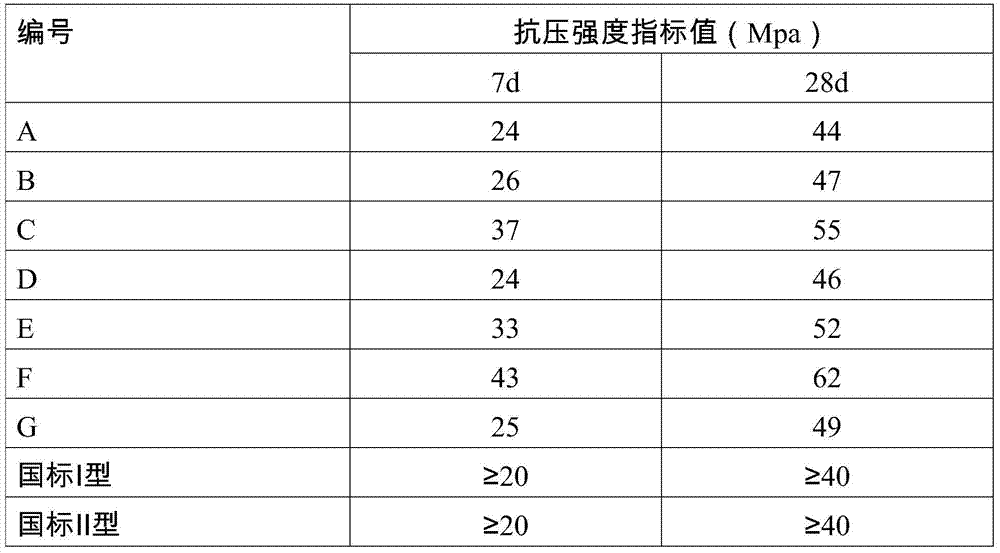

Examples

Embodiment 1

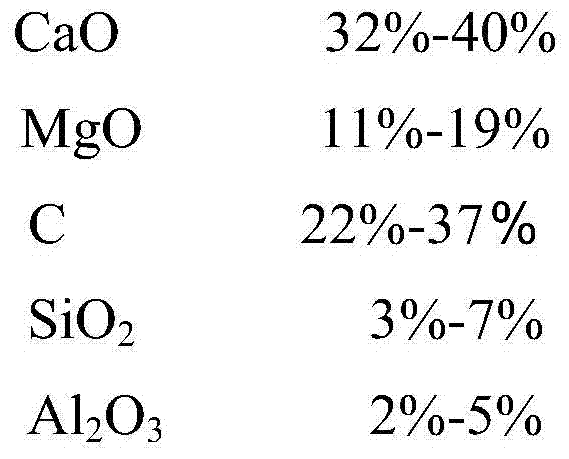

[0036] Calcium carbide purified ash 100 parts as raw meal, its composition is: CaO 37.94%, MgO 12.33%, C 34.17%, SiO 2 6.32%, Al 2 o 3 3.37%. Prepare cement-based material expansion agent according to the following steps:

[0037] The raw meal is dried at 105±5°C until the weight loss value is not more than 5 / 10,000, and the dried raw meal is calcined at a high temperature under the following conditions: the calcining temperature is 810°C, the calcining time is 120min, and the holding time is 120min, the heating rate is 5°C / min; after cooling, calcined pellets are obtained (the sum of MgO and CaO content in the calcined pellets is 76.15%, and the ratio of calcium to magnesium is 3.07), and the specific surface area obtained by grinding is 433m 2 / kg cement-based material expansion agent A.

Embodiment 2

[0039] Every 100 parts by mass of raw meal is composed of 80 parts of calcium carbide purified ash and 20 parts of calcium and magnesium regulating components. Among them, the composition of calcium carbide purified ash is: CaO 32.31%, MgO 13.66%, C 27.92%, SiO 2 5.28%, Al 2 o 3 4.11%; calcium and magnesium adjustment components are 10 parts of magnesite tailings and 10 parts of dolomite tailings, the chemical composition of magnesite tailings is MgO 43.66%, CaO 1.71%, SiO 2 1.58%, Al 2 o 3 0.41%, Fe 2 o 3 0.47%, Loss (loss on ignition) 50.47%; chemical composition of dolomite tailings is CaO31.72%, MgO21.28%, SiO 2 0.96%, Fe 2 o 3 2.18%, Loss 42.78%. The magnesite tailings and dolomite tailings ores are crushed and ground to a fineness of 80 μm square hole sieve, and the sieve residue is less than 10%. Prepare cement-based material expansion agent according to the following steps:

[0040] Calcium carbide purified ash and calcium and magnesium adjustment components ...

Embodiment 3

[0042] Every 100 parts by mass of raw meal is composed of 85 parts of calcium carbide purified ash and 15 parts of calcium and magnesium regulating components. Among them, the calcium carbide purified ash is composed of: CaO 37.94%, MgO 12.33%, C 34.17%, SiO 2 6.32%, Al 2 o 3 3.37%; calcium and magnesium adjustment components are 10 parts of magnesite tailings and 5 parts of dolomite tailings, the chemical composition of magnesite tailings is MgO 43.66%, CaO 1.71%, SiO 2 1.58%, Al 2 o 3 0.41%, Fe 2 o 3 0.47%, Loss50.47%; Dolomite tailings chemical composition is CaO 31.72%, MgO 21.28%, SiO 2 0.96%, Fe 2 o 3 2.18%, Loss 42.78%. The magnesite tailings and dolomite tailings ores are crushed and ground to a fineness of 80 μm square hole sieve, and the sieve residue is less than 10%. Prepare cement-based material expansion agent according to the following steps:

[0043] Calcium carbide purified ash and calcium and magnesium adjustment components are evenly mixed to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com