A kind of preparation method of polyethylene glycol modified graphene oxide

A polyethylene glycol modification, polyethylene glycol technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc. It does not affect the workability, the short process flow, and the effect of strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

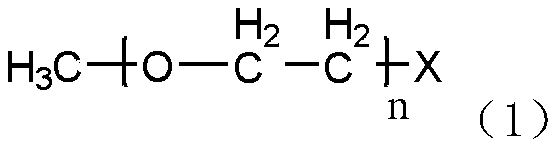

Method used

Image

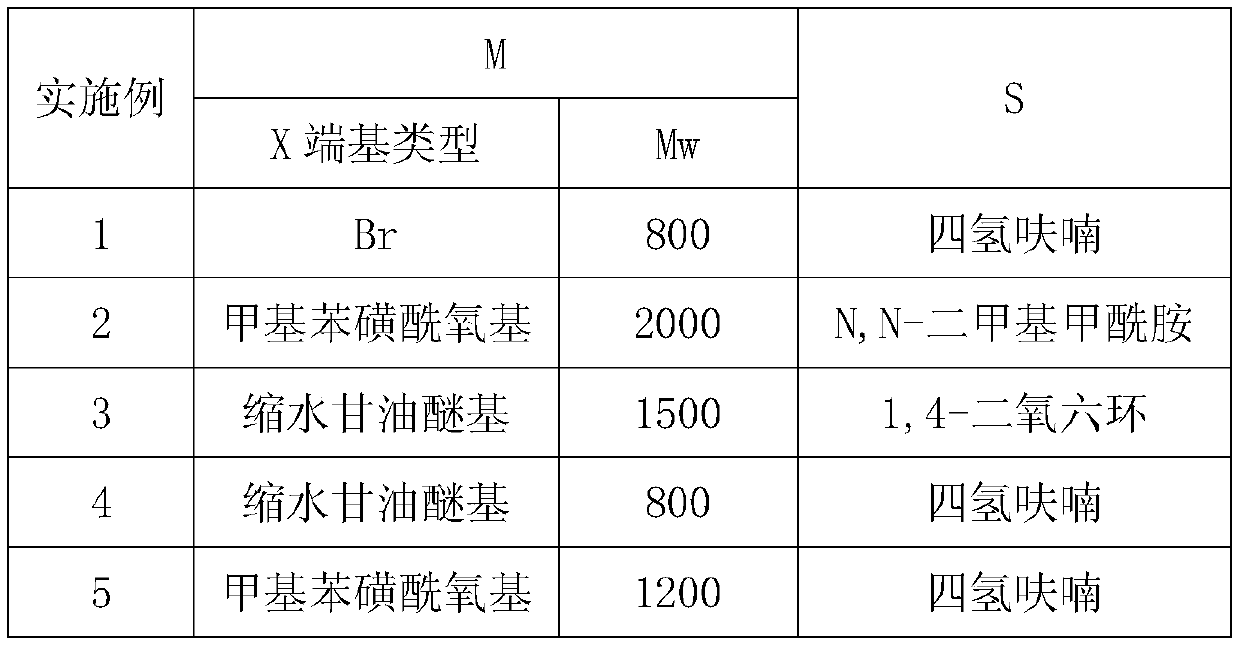

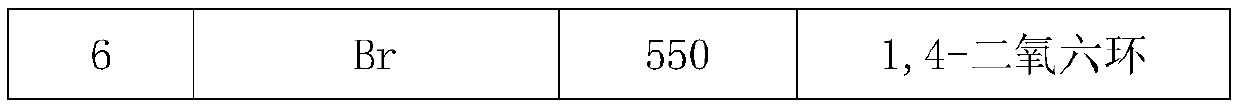

Examples

Embodiment 1

[0035] In an inert gas protection and drying environment, add 1 part of dried graphene oxide G to 500 parts of dried tetrahydrofuran, and ultrasonically disperse the system until a uniform dispersion is formed, then cool to 30 degrees Next, add 0.06 parts of sodium hydride (net mass), stir for 2 hours, and ensure that the temperature does not exceed 30 degrees during the stirring process, after that, add 0.6 parts of bromomethyl polyethylene glycol (Mw=800) The reaction was stirred for 24h. After the reaction was completed, 1.2 times the molar amount of sodium hydride was added to neutralize the sample with acetic acid, then concentrated by high-speed centrifugation, and the solvent was evaporated under reduced pressure to obtain polyethylene glycol-modified graphene oxide 1.

Embodiment 2

[0037]In an inert gas protection and dry environment, add 1 part of dried graphene oxide G to 500 parts of dried N,N-dimethylformamide, and ultrasonically disperse the system until a uniform dispersion is formed. After that, cool it to below 30 degrees, add 0.04 parts of sodium hydride (net mass), stir for 1 hour, and ensure that the temperature does not exceed 30 degrees during the stirring process, and then add 1.2 parts of methylpolyethylene p-toluenesulfonate Alcohol ester (Mw=2000), stirred and reacted at 30 degrees for 24h. After the reaction was completed, 1.2 times the molar amount of sodium hydride was added to neutralize the sample with acetic acid, then concentrated by high-speed centrifugation, and the solvent was evaporated under reduced pressure to obtain polyethylene glycol-modified graphene oxide 2.

Embodiment 3

[0039] In an inert gas protection and dry environment, add 0.5 parts by mass of dried graphene oxide G to 500 parts by mass of dried 1,4-dioxane, and ultrasonically disperse the system until a uniform dispersion is formed. , after that, cool down to below 30 degrees, add 0.02 parts of sodium hydride (net mass), stir for 2 hours, and ensure that the temperature does not exceed 30 degrees during the stirring process, and then add 0.8 parts of quality methyl polyethylene glycol glycidyl ether ( Mw=1500), stirred and reacted at 45 degrees for 24h. After the reaction was completed, 1.2 times the molar amount of sodium hydride was added to neutralize the sample, and then concentrated by high-speed centrifugation, and then the solvent was evaporated under reduced pressure to obtain polyethylene glycol-modified graphene oxide 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com