One-row sandy soil peanut harvester

A technology for peanut harvesters and sandy soils, which is applied in the direction of digging harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of high labor intensity, low efficiency, and expensive prices, and achieve high prices, good performance, and structural advantages. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

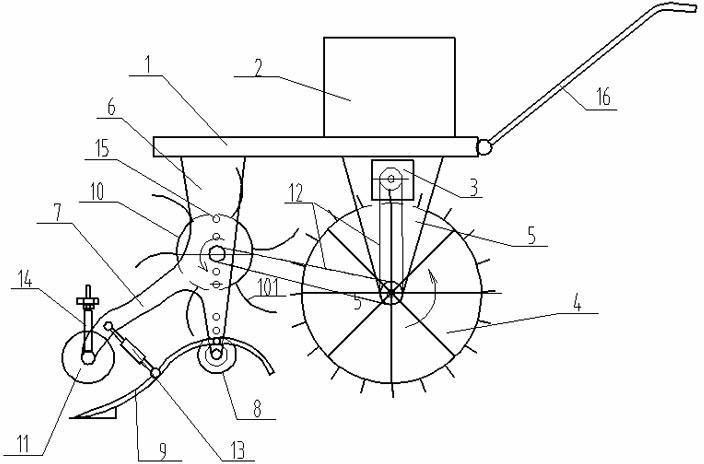

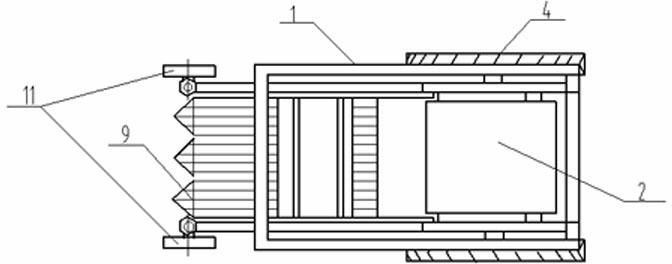

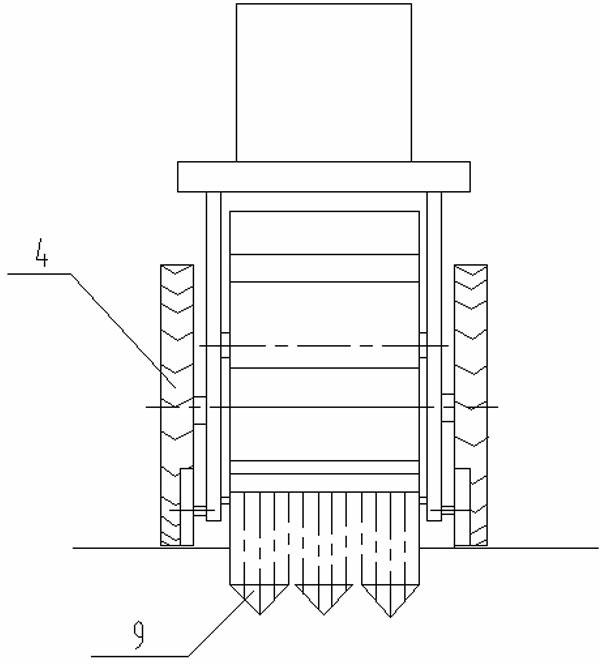

[0021] As shown in the figure, a single row sandy soil peanut harvester is mainly composed of frame 1, engine 2, reducer 3, traveling wheel 4, support frame I5, support frame II6, support frame III7, free wheel 8, coulter 9, Composed of a reel 10 and a depth-gauge wheel 11, the engine 2 is arranged on the upper end of the frame 1, and the engine transmits the power to the traveling wheels through a reducer. On the frame 1, the support frame II6 is arranged at the front end of the support frame I5, that is to say, the support frame II6 is arranged on the side where the support frame I5 is located in the direction in which the traveling wheels advance. The upper end of the support frame II6 is fixedly connected with the frame 1, and the lower end is free end, the free wheel 8, the coulter 9, and the reel 10 are set on the support frame II6 through the rotating shaft from bottom to top in turn, and the support frame II6 is uniformly provided with adjustment holes 15 from the lowes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com