Folding machine fence panels with front gauge guides

A guide device and front gauge technology, which is applied in the field of folding machines, can solve the problems of inaccurate paper folding accuracy, affecting the folding accuracy of the folding machine, and difficult adjustment of the front gauge components, so as to avoid the front gauge The effect of gauge bumping against paper swinging, preventing deformation, and moving flexibly and accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

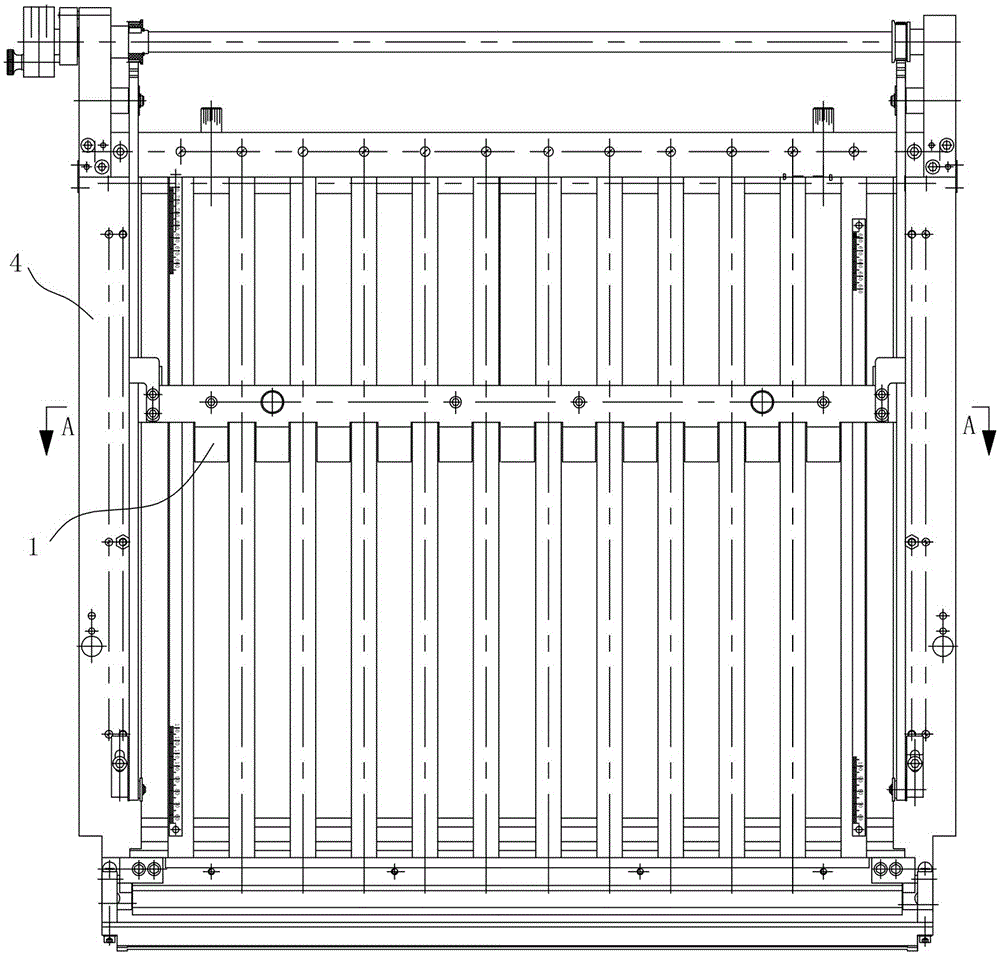

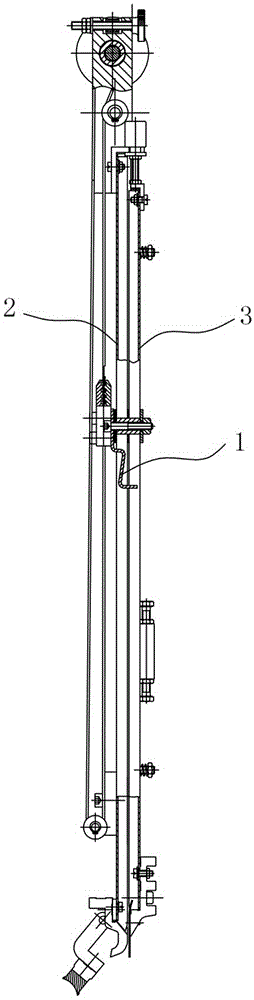

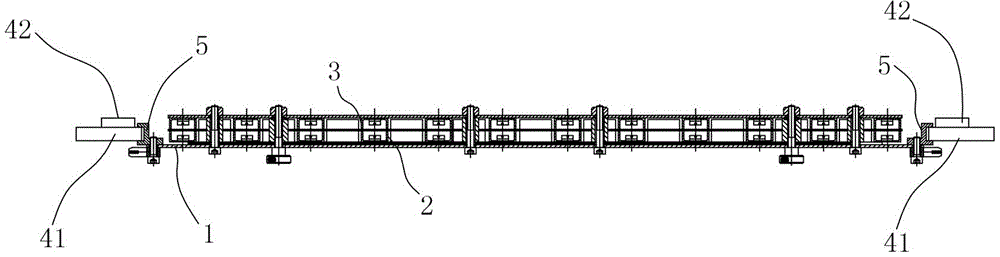

[0016] Figure 1 to Figure 4 It shows an embodiment of a folding machine fence panel with a front gauge guide device of the present invention, and the folder fence panel includes a front gauge assembly 1, a plurality of paper pressing rods 2, a plurality of paper supporting rods 3 and A pair of support plate assemblies 4 arranged in parallel, the paper pressure rod 2 and the paper support rod 3 are arranged in pairs to form multiple groups of rod groups, and the multiple groups of rod groups are arranged in parallel between a pair of support plate assemblies 4, and the front gauge assembly 1 is empty Set on multiple groups of rods, at least one end of the front gauge assembly 1 is equipped with a guide block 5 that cooperates with the support plate assembly 4, and the front gauge assembly 1 is adjusted by the cooperation between the guide block 5 and the support plate assembly 4. It is adjusted for stable and reliable guidance, and the structure guided by the contact and coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com