Peristaltic pump

A technology of hose pumps and hoses, which is applied in the field of hose pumps and can solve the problems of valve cleaning and insufficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

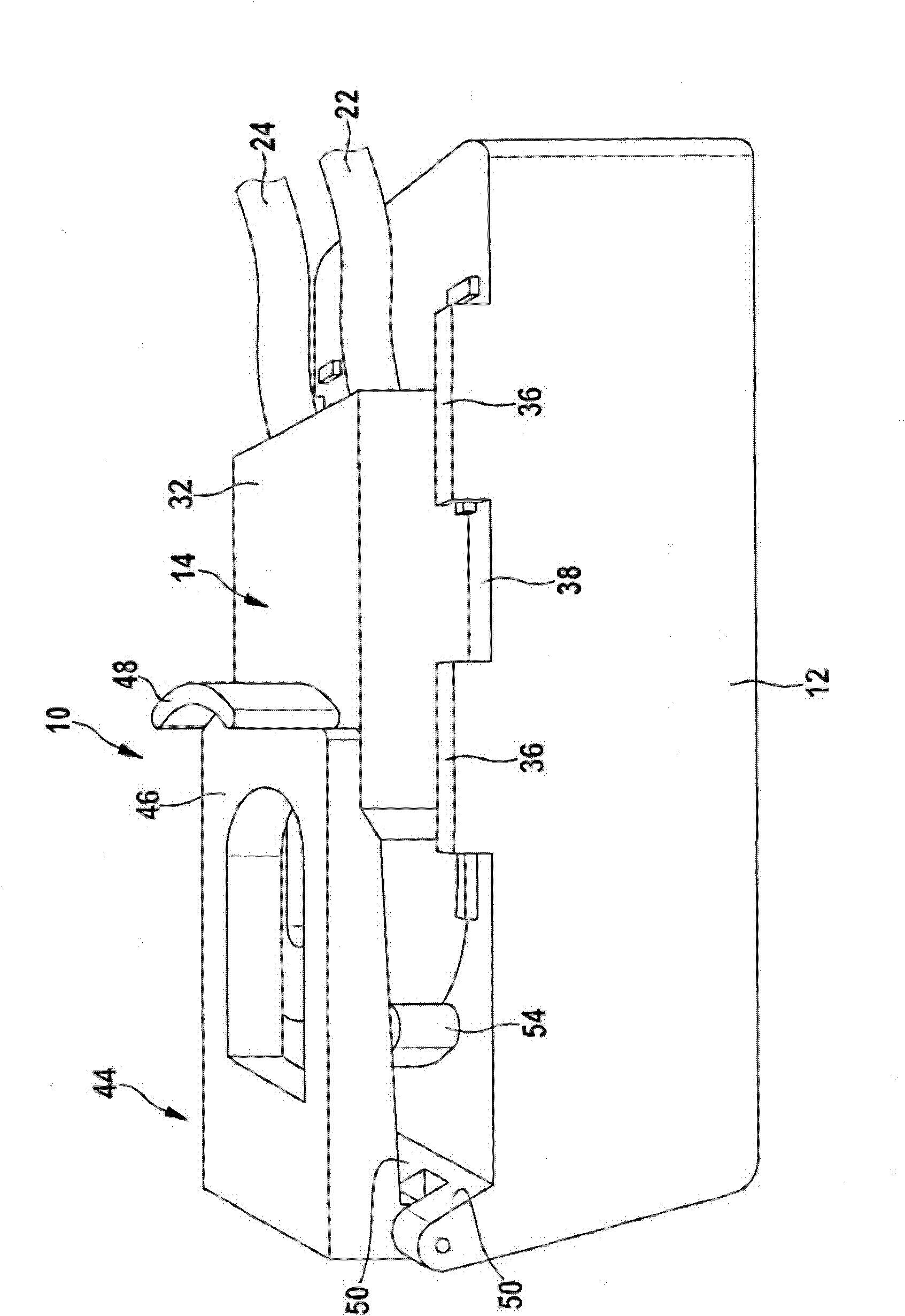

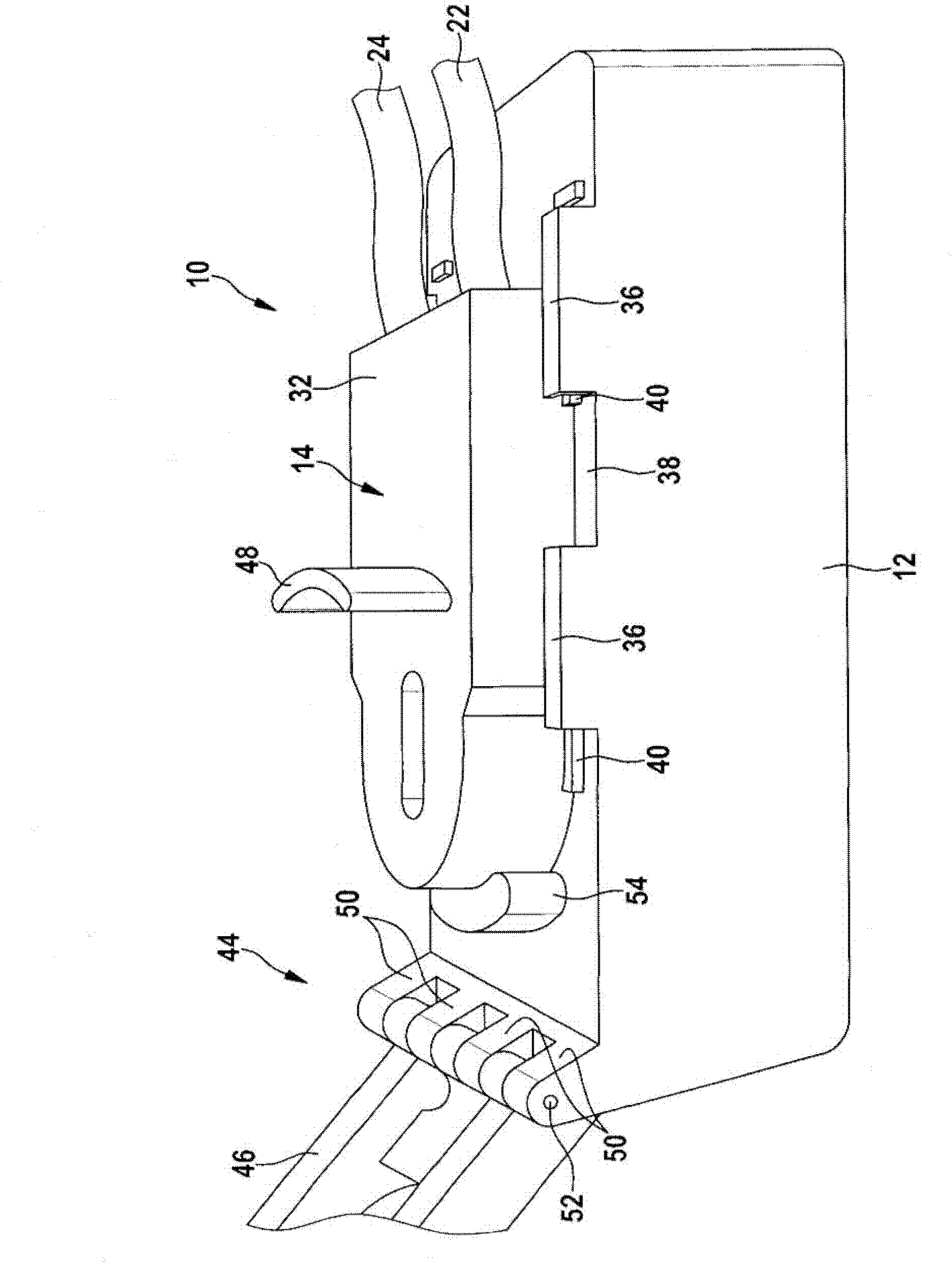

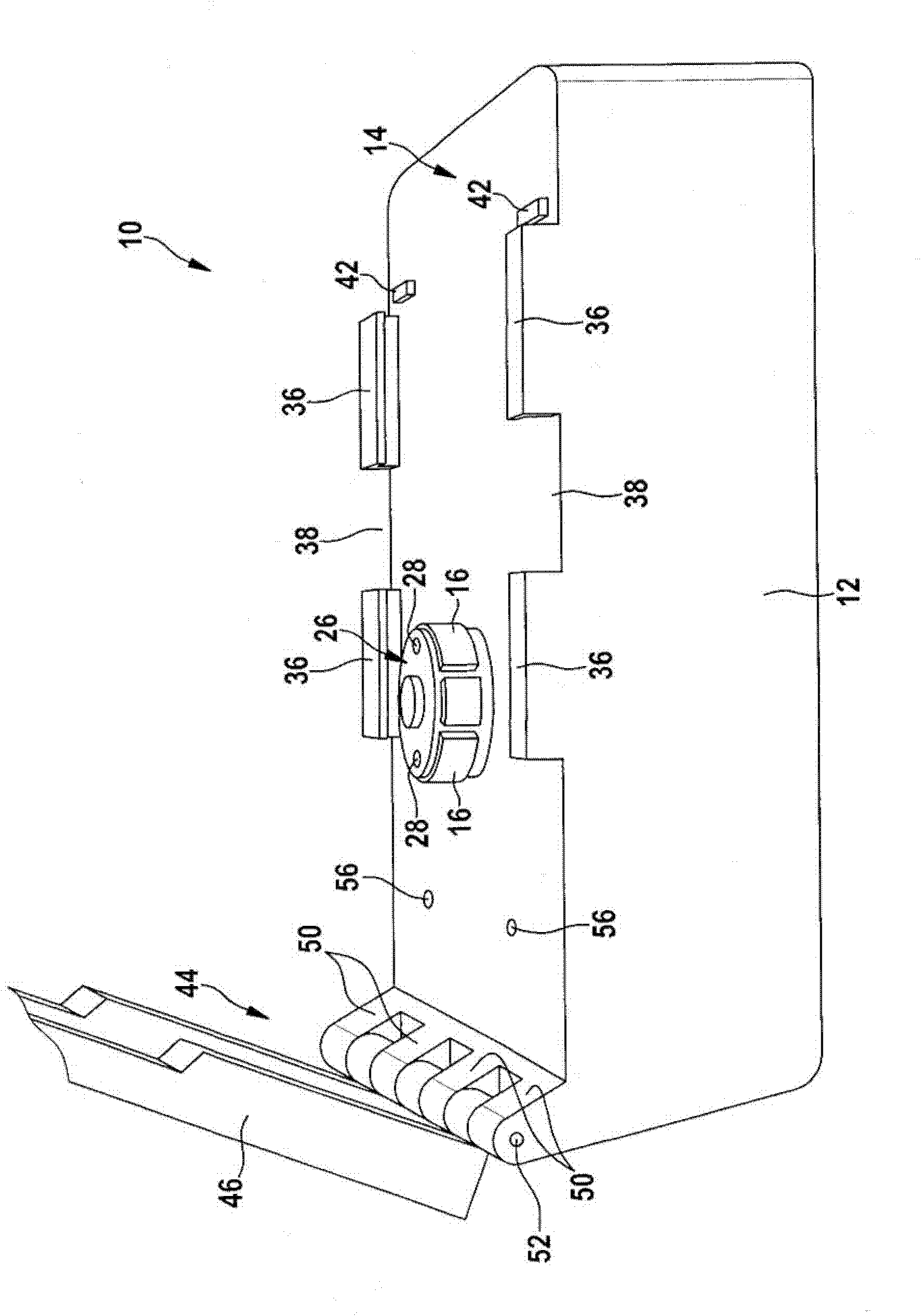

[0023] Figures 1 to 4 A hose pump 10 according to an embodiment of the invention is shown, which can be used, for example, as a conveying device for paint application devices, commonly also referred to as motorized paint rollers, in order to convey especially thin liquid dispersion paints, latexes Paints, water-dilutable primers, lacquers, oils and water-based wood preservatives. The hose pump 10 comprises a pump housing 12 which receives a drive motor, not shown in detail, and a pump head 14 arranged on the pump housing, which has a deformation body 16 in the form of a pressure roller which can be driven by the drive motor and a pump hose 18 which is supported on the pump housing 12 and which is mechanically deformed by the deformation body 16 during operation of the hose pump in order to move the medium to be conveyed through the pump hose 18 . A suction line 22 on the one hand and a pressure line 24 on the other hand are fastened to the pump hose 18 via corresponding coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com