Backlight module and liquid crystal display device

A backlight module and backplane technology, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of reducing A value and affecting the display effect of the backlight module optical quality liquid crystal display device, etc. The effect of increasing the display area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

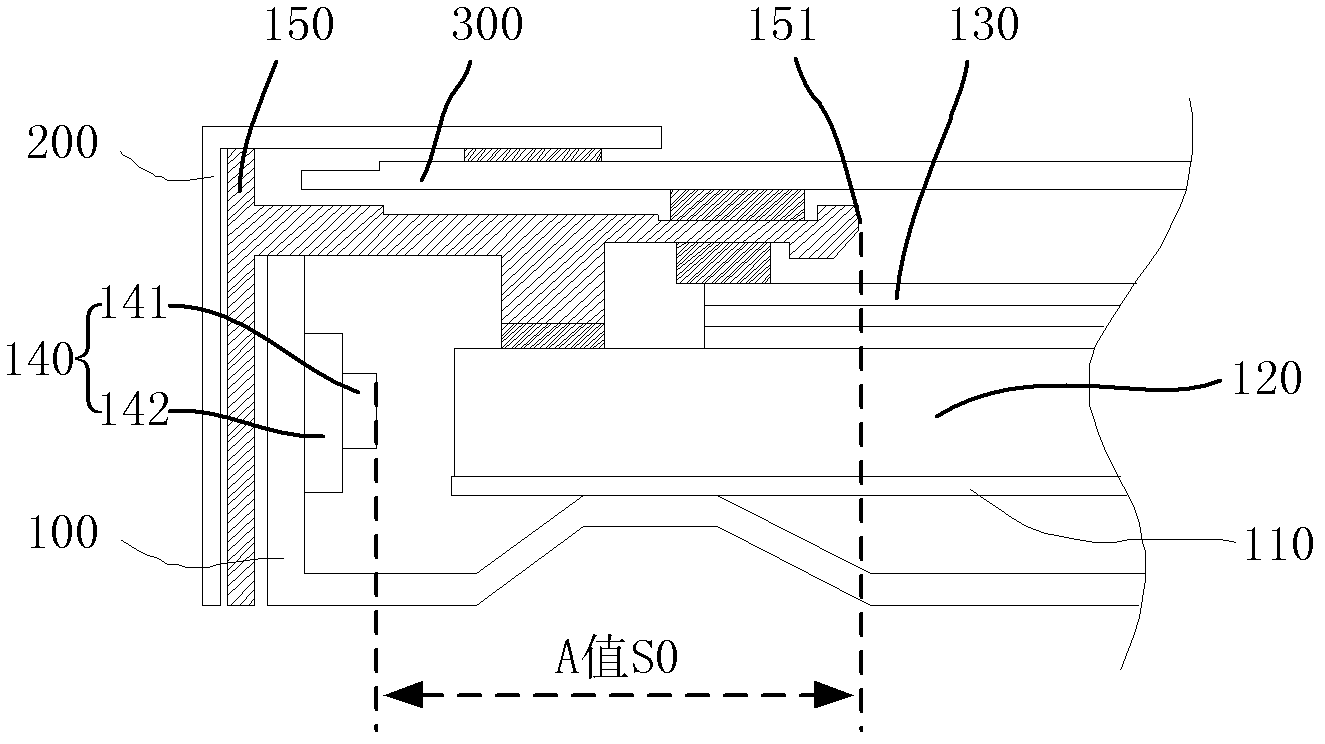

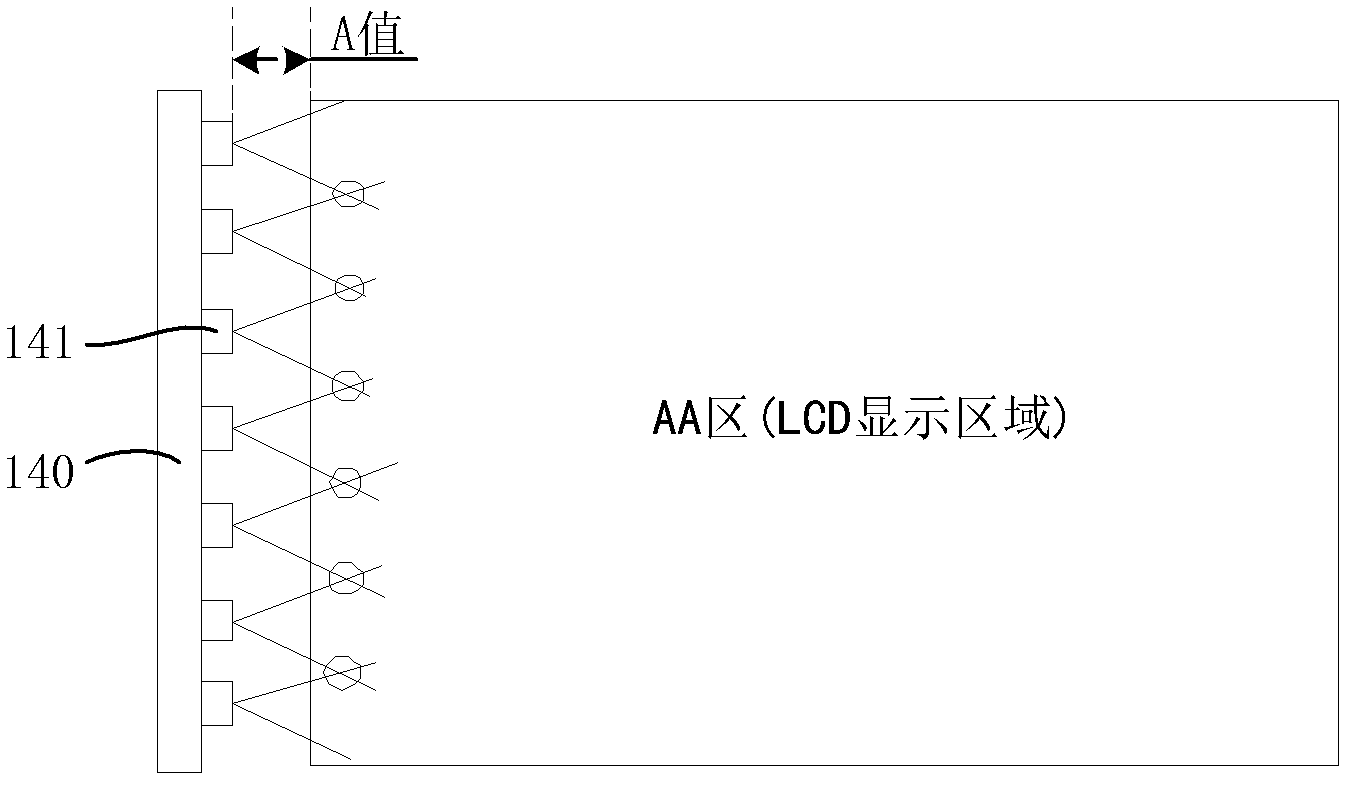

[0030] Such as Figure 4 Shown is Embodiment 1 of the present invention. The backlight module of the liquid crystal display device includes: a backplane 100, a reflection plate 110 placed on the backplane 100, a light bar 140 placed on the reflection plate 110 and opposite to the The light guide plate 120, the plastic frame 150 and the outer frame 200 arranged outside the back plate 100 and pressed together with the light guide plate 120, the optical film 130 is arranged on the light-emitting surface of the light guide plate 120, the liquid crystal panel 300 is composed of the plastic frame 150, the outer frame 200 and other components are fixed above the backlight module; wherein, the backplane 100 and the side walls of the plastic frame 150 are provided with through holes, and the through holes form a light-incident surface relative to the light guide plate 120 that extends outside the backlight module. Recess, the light bar 140 as a light source is set in the depression, an...

Embodiment 2

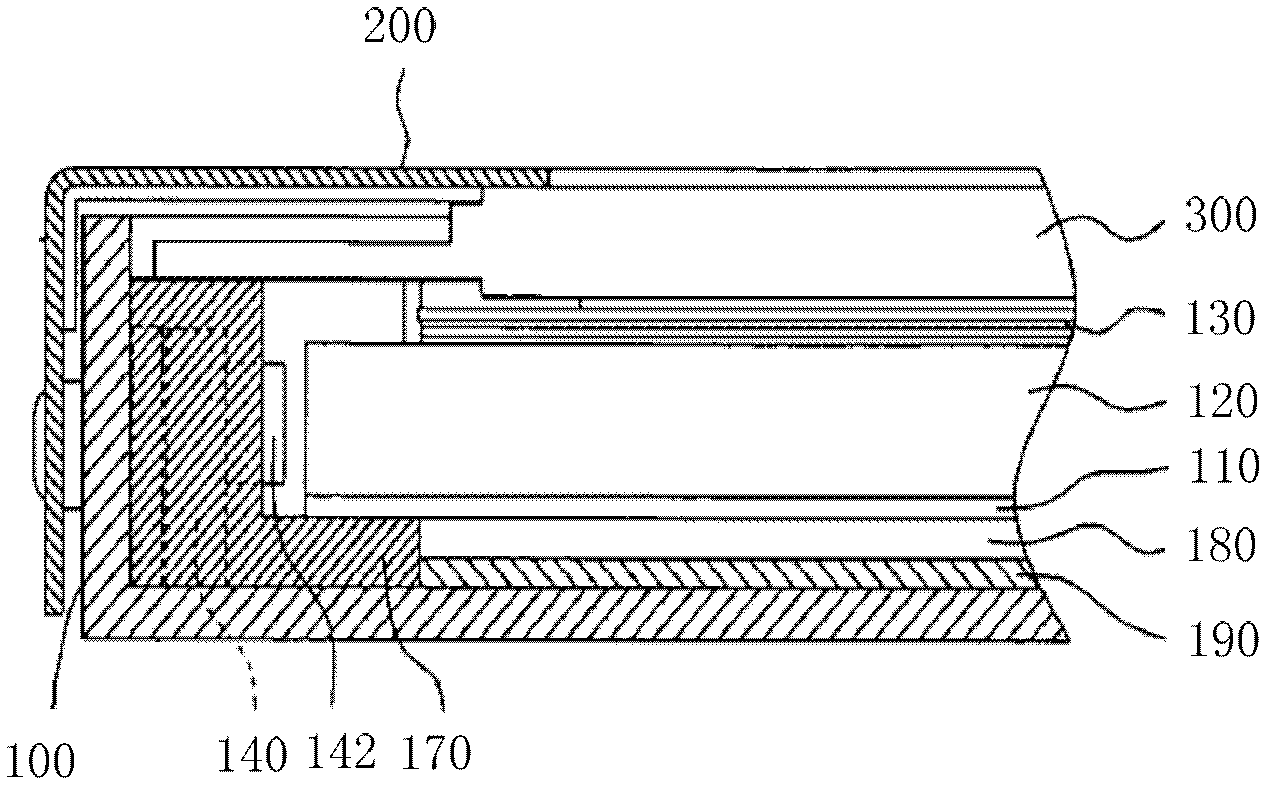

[0034] Such as Figure 5 Shown is the second embodiment of the present invention. The difference from the first embodiment is that in this example, the light bar 140 of the outer frame 200 is installed with a boss 210 extending toward the inside of the backlight module. The boss 210 Corresponding to the depression formed by the through holes on the back plate 100 and the plastic frame 150, the depth of the boss 210 is less than the sum of the thickness of the side wall of the back plate 100 and the thickness of the side wall of the plastic frame 150, and also That is to say, the boss 210 does not protrude from the concave surface of the depression and the bottom surface of the boss 210 is not flush with the concave surface, and the light bar 140 is installed on the bottom surface of the boss 210, The purpose of doing this is to facilitate positioning when the backlight module is assembled, and to improve the accuracy and efficiency of assembly. Such as Figure 5 As shown in ...

Embodiment 3

[0037] Such as Image 6 Shown is the third embodiment of the present invention. In this embodiment, the backlight module of the liquid crystal display device includes: a back plate 100, a reflective plate 110 placed on the back plate 100, and a reflective plate 110 placed on the reflective plate 110. The light guide plate 120 facing the light bar 140 , the plastic frame 150 and the outer frame 200 arranged outside the back plate 100 and pressed against the light guide plate 120 , the optical film 130 is arranged on the light-emitting surface of the light guide plate 120 , and the liquid crystal panel 300 is composed of Components such as the plastic frame 150 and the outer frame 200 are fixed above the backlight module; wherein, the side wall of the plastic frame 150 is provided with a through groove corresponding to the installation position of the light bar 140, and the back plate 100 is provided with a curved groove at this position. fold 101, the bend 101 is submerged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com