LED driver

A technology of LED driver and rectifier bridge, applied in the field of LED lamp driver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

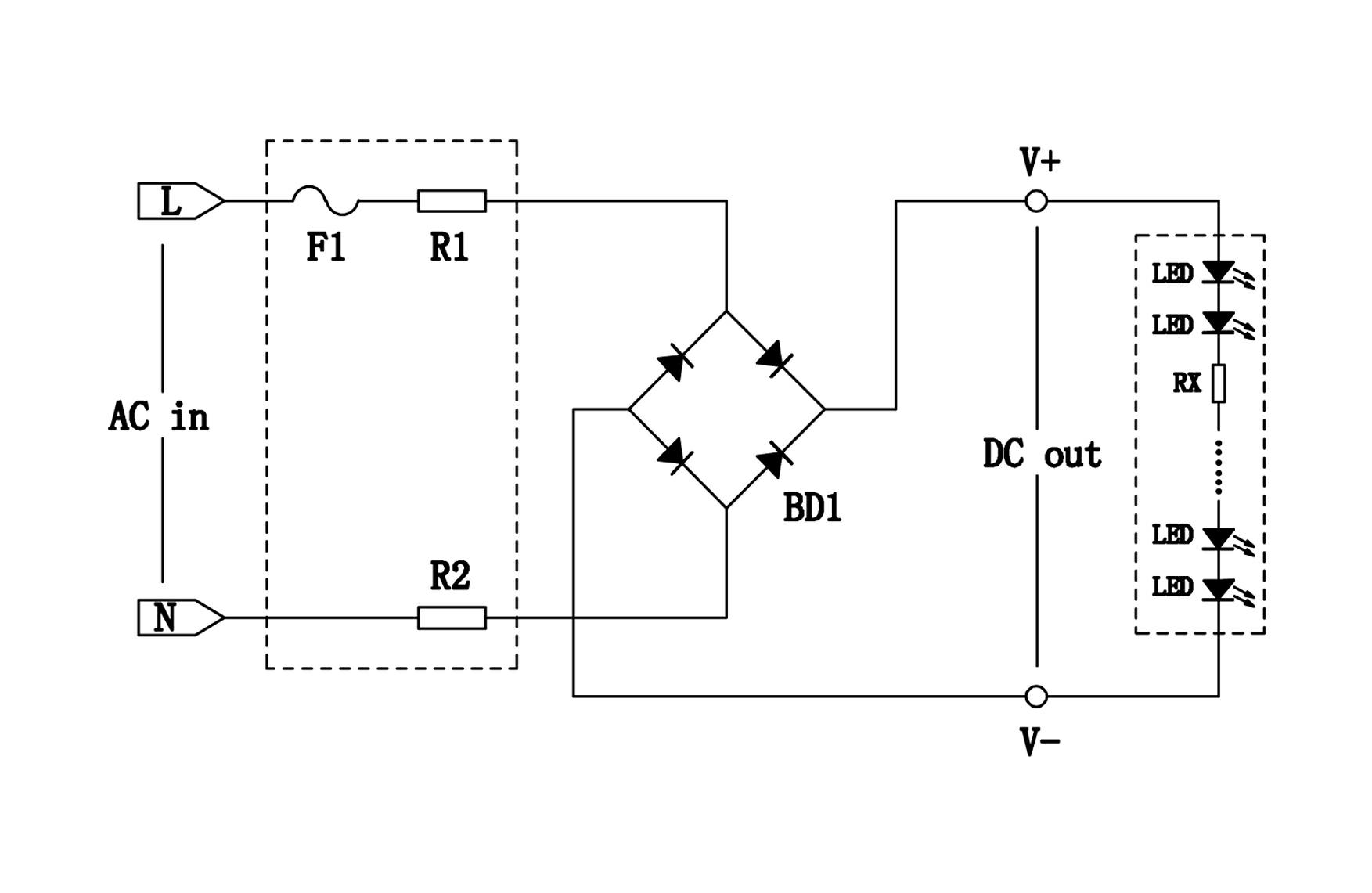

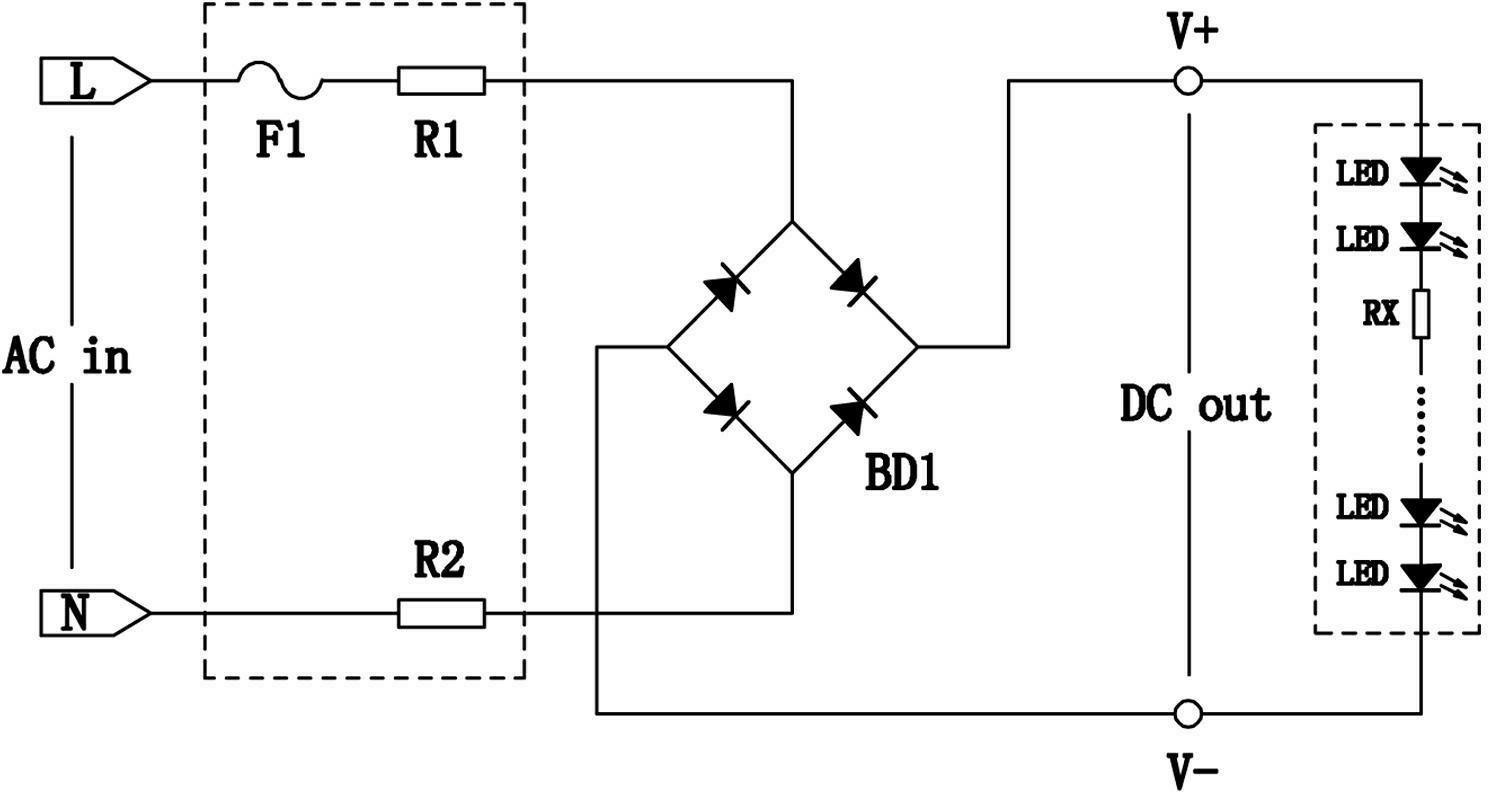

[0015] refer to figure 1 , an LED driver, which consists of a rectifier bridge circuit BD1 and a pre-protection circuit connected to the mains input terminal of the rectifier bridge circuit BD1 (shown in the dotted line box where F1, R1, and R2 are located in the figure), and the LED load is directly connected to the rectifier bridge The output terminal of the LED load (indicated by the dotted line box where LED and RX are located in the figure) is connected in series with a current-limiting resistor RX.

[0016] The pre-protection circuit includes current-limiting resistors R1, R2 and fuse F1 connected in series to the mains input line to protect the circuit.

[0017] The driver of the present invention omits the capacitive filter circuit in the traditional LED drive circuit, overcomes the technical prejudice that the capacitive filter circuit must be added in the traditional LED drive circuit, although the LED load will produce 100Hz flicker after the capacitive filter circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com