Microlite external wall fire-prevention and heat-preservation integral plate and microlite materials thereof

A technology of fire prevention and heat preservation and microcrystalline stone, which is applied in covering/lining, construction, building structure, etc., can solve the problems of fire prevention, heat preservation, decorative decorative panels, large area occupied by heat preservation materials, frequent fire accidents, etc., and achieve The effect of national property and people's life and property safety protection, saving installation resources and occupied area, good fire insulation and external decoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

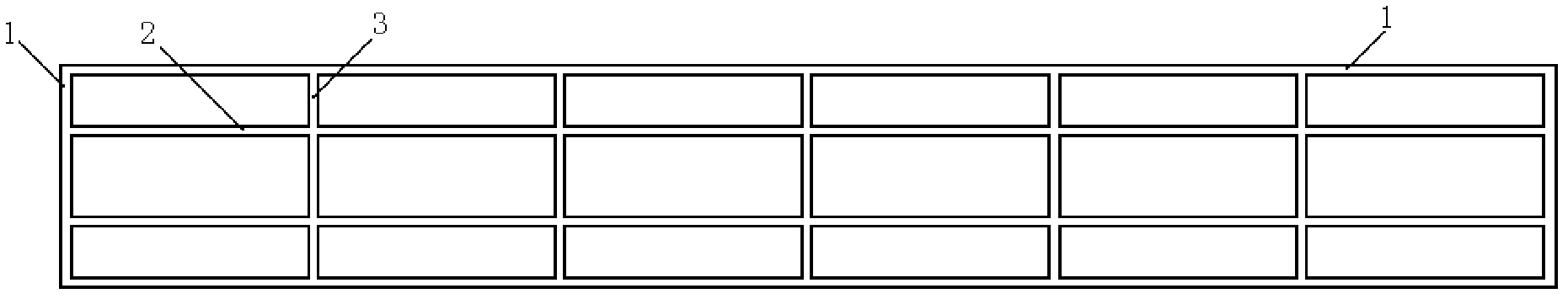

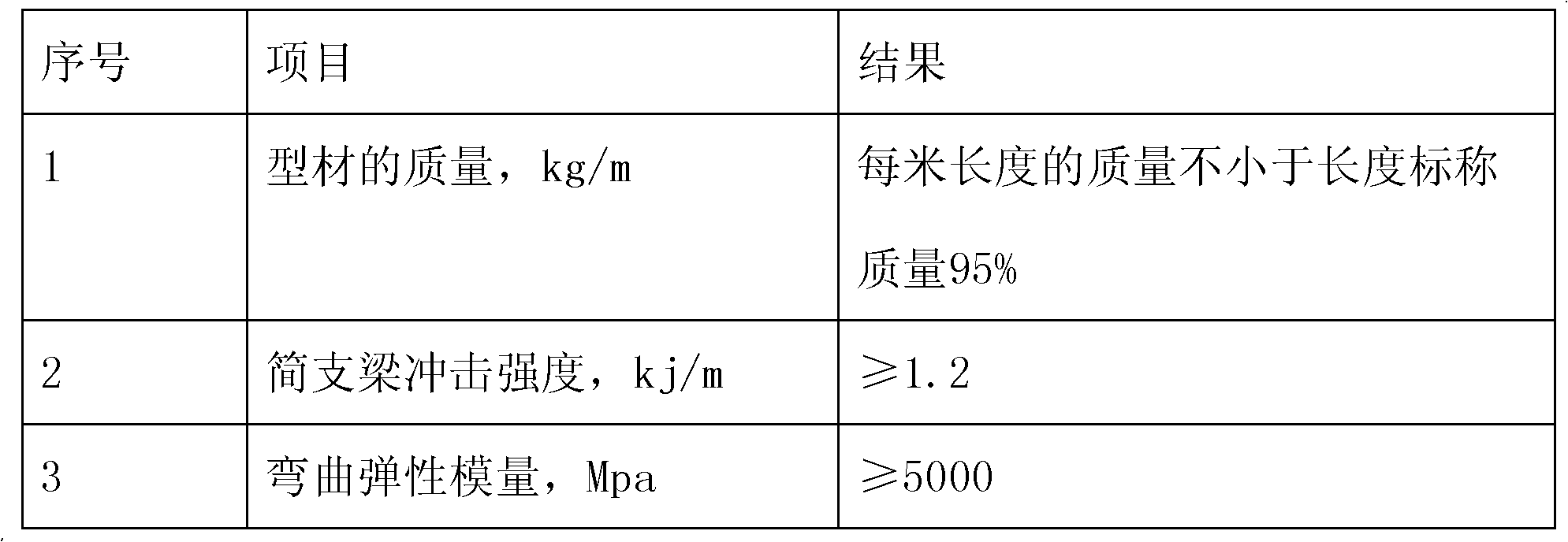

[0038] Raw materials (percentage by weight): 54% microcrystalline stone; 12% PVC resin; 5% composite stabilizer; 5% DOP; 5% decabromodiphenylethane; 9% magnesium hydroxide; 2% antimony trioxide; stearin Acid 8%. Production process: multi-layer hollow board according to the requirements of the drawing, mold production, mold installation, equipment and mold heating, batching and mixing, when the natural mixing temperature reaches 120 ° C, select the pellets, and then add the pellets to the molding material In the process, the extruded products are sanded and grooved, and then enter the paint shop for surface treatment. After passing the inspection, they are packaged and put into storage.

Embodiment 2

[0040] Raw materials: 55% microcrystalline stone; 12% PVC resin; 5% composite stabilizer; 5% DOP; 5% decabromodiphenylethane; 10% magnesium hydroxide; 2% antimony trioxide; 6% stearic acid. The manufacturing process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com