Coil outlet end transition connecting device of high-voltage current conversion transformer and manufacture method of coil outlet end transition connecting device

A converter transformer and transition connection technology, applied in the direction of transformer/inductor coil/winding/connection, connection, coupling device, etc., can solve problems such as uneven distribution of electric field intensity at the end of the coil, potential safety hazards, and defective manufacturing methods , to improve the distribution of electric field intensity, ensure safety and reliability, and improve the effect of insulation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

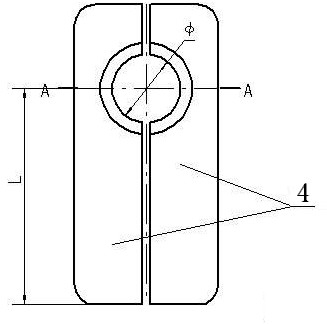

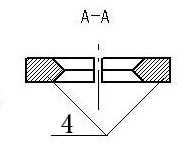

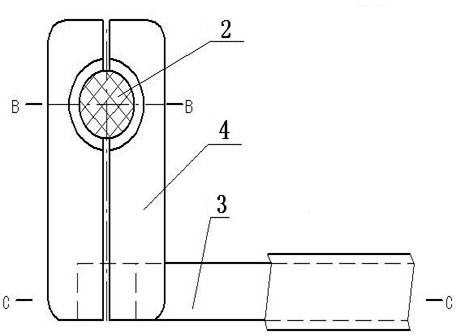

[0022] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a coil 1, a lead wire 2 and a coil lead wire 3, the lead wire 2 is welded to the opening end of the copper plate 4, the coil lead wire 3 is welded to the lead wire end of the copper plate 4, the lead wire 2, the coil lead wire 3 and the copper plate 4 Insulating paper 5 is respectively wrapped, and an insulating cardboard 6 is arranged between the copper plate 4 and the wire cake at the end of the coil 1 . The thickness of the insulating paper 5 is greater than the insulation thickness of the original wire. The four edges of the copper plate are chamfered.

[0023] The manufacturing method of the high-voltage converter transformer coil outlet transition connection device according to the present invention comprises the following steps:

[0024] a. Make the transition connection copper plate: the end of the opening is the lead end, and the other end is the wire end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com