Construction method of large I-beam butt joint operation

A construction method and I-beam technology, which is applied in the fields of construction, building structure, and building materials processing, can solve the problems of difficult construction, long crane time, and difficult precision control, so as to reduce the difficulty of operation and reduce the construction cost. cost, and the effect of improving the accuracy of docking operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

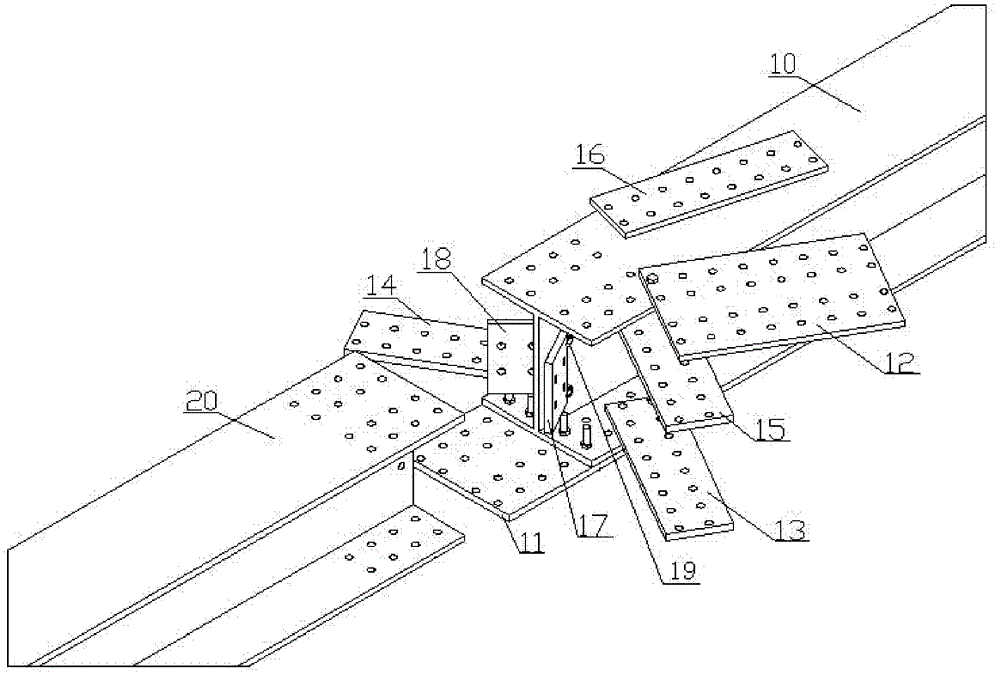

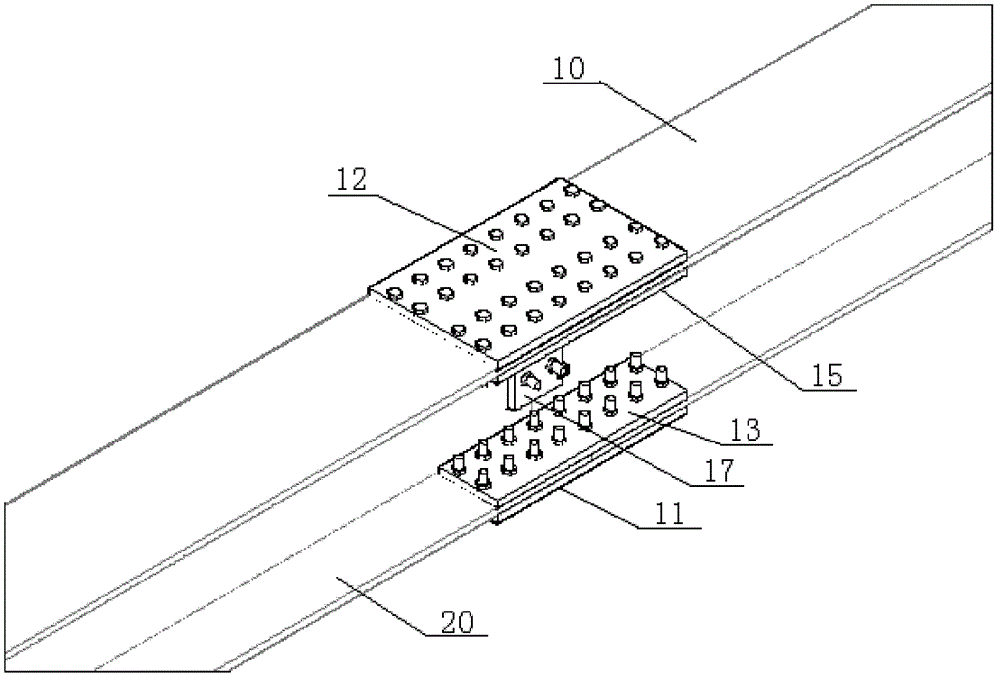

[0019] In order to reduce the construction difficulty, improve the construction efficiency, and also to improve the butt joint accuracy in the construction process, the present invention pre-installs the auxiliary connector for connecting the two I-beams on one of the I-beams, and then uses the auxiliary connector to connect the other I-beams. The precise positioning of the I-beams enables fast docking of the I-beams.

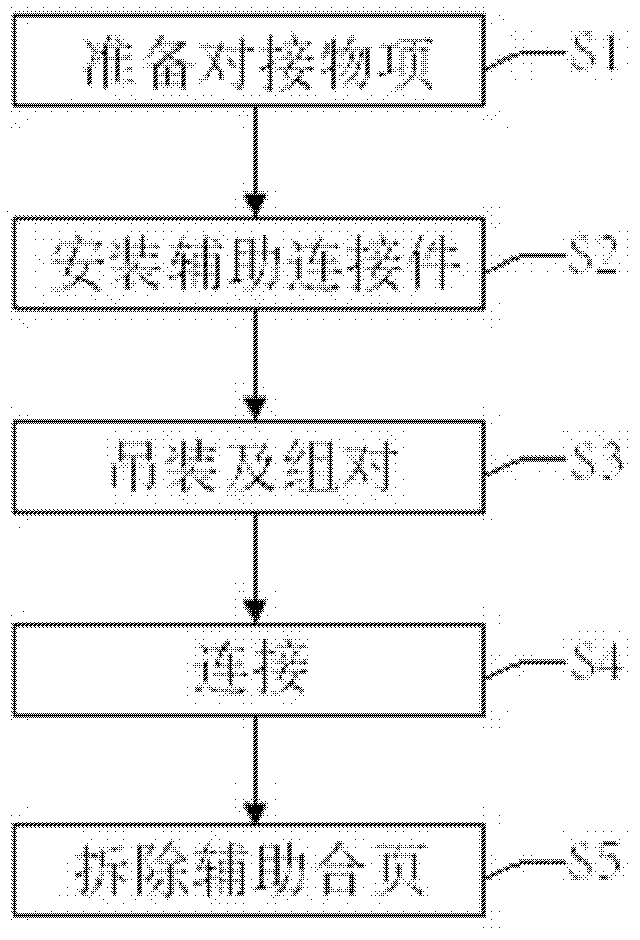

[0020] see Figure 1 to Figure 3 , the large-scale I-beam butt joint operation construction method of the present invention comprises the following steps:

[0021] S1. Prepare docking items: prepare the two I-beams 10, 20 to be docked and the sheet-shaped auxiliary connectors 11-18 for connecting the two I-beams 10, 20, and accurately lay out the wires according to the design requirements. The positions of the connection holes are marked respectively on the two I-beams 10, 20 and the auxiliary connectors 11-18 and auxiliary connection holes are provided;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com