Drawing type work light

A work light and pull-out technology, which is applied to lighting devices, electric light sources, components of lighting devices, etc., can solve the problems of easy damage to the lamp body and large size of the work light, so as to reduce the volume and avoid bumps. Damaged, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings of the description.

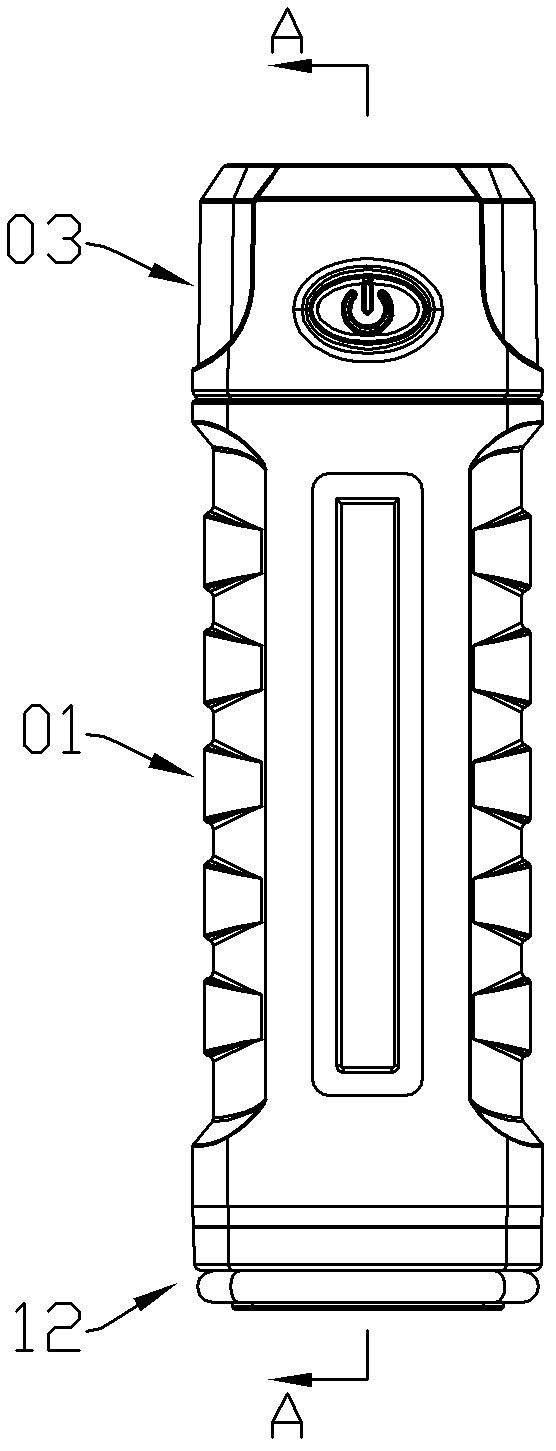

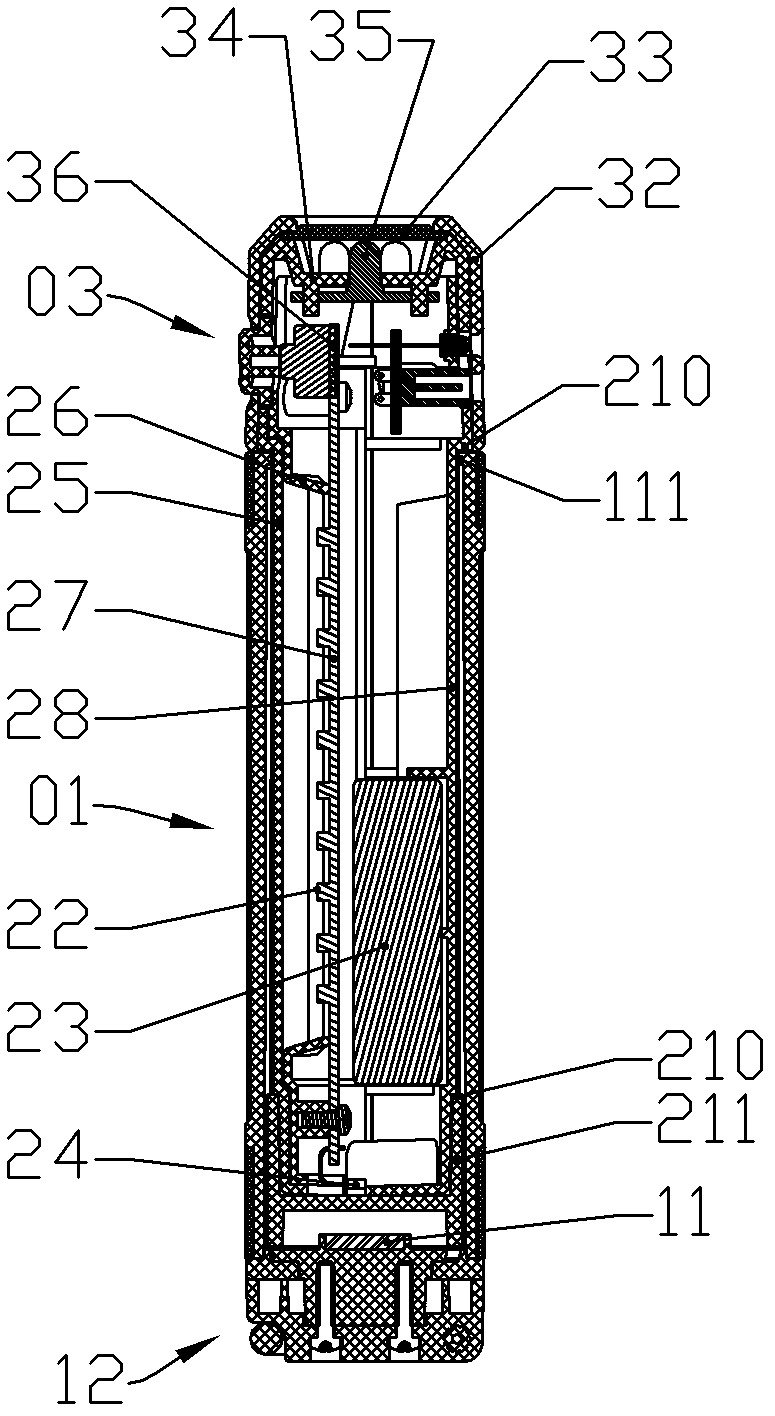

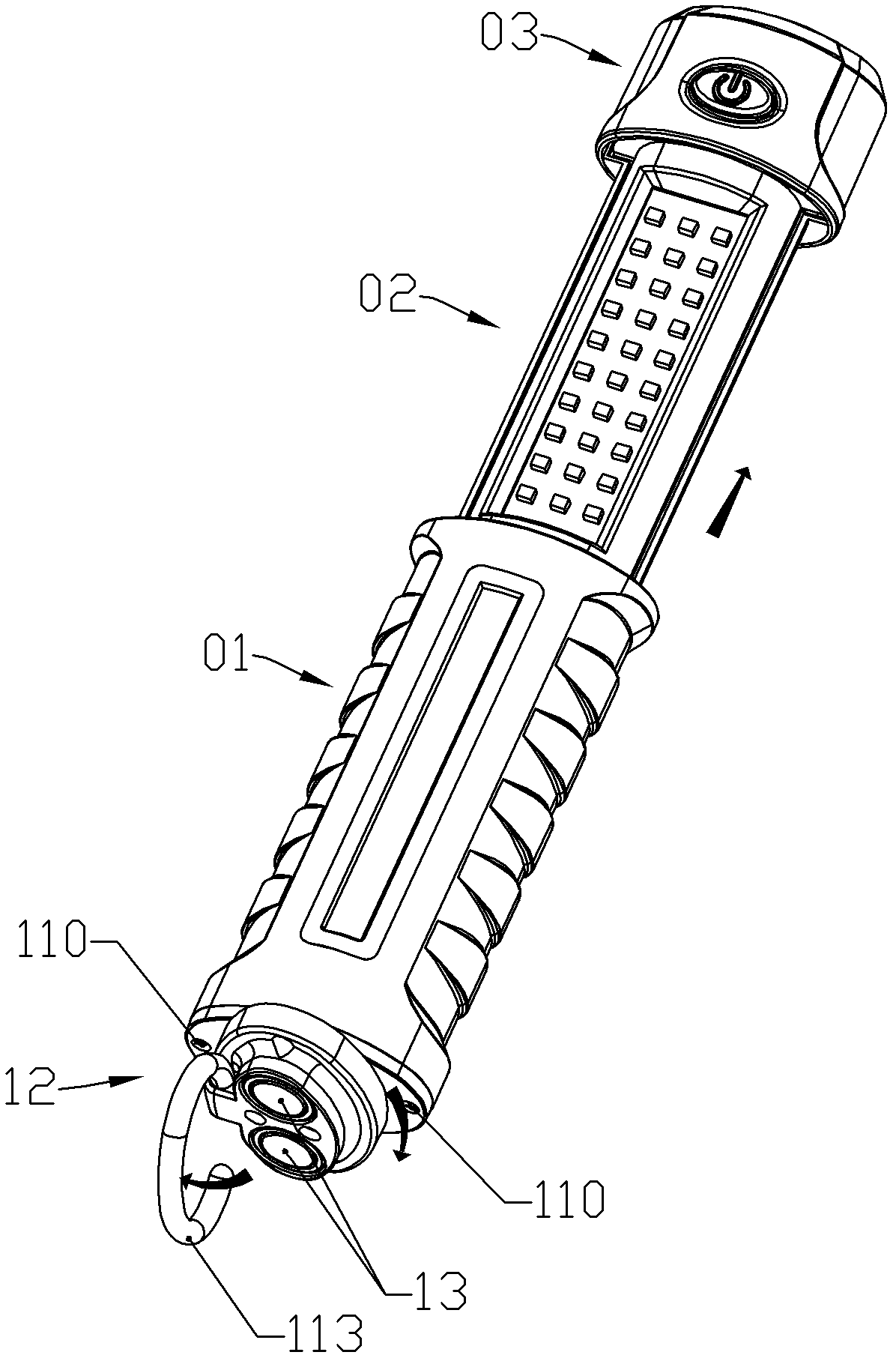

[0023] The pull-out work light of the present invention, such as Figure 1-4 shown, which includes:

[0024] The frame body 01 is provided with a permanent magnet 11 (such as a magnetic steel);

[0025] The pull-out lamp 02 is telescopically assembled on the frame body 01. The pull-out lamp 02 includes a lamp body 21 assembled with the frame body 01 and includes an electric light source 22, a power supply 23, a contactless The lighting circuit of the point sensor switch 24 (such as a Hall switch);

[0026] The electric light source 22 is stored in the frame body 01 when the pull-out lamp 02 is retracted on the frame body 01 and the permanent magnet 11 makes the non-contact induction switch 24 disconnect the lighting circuit, and the electric light source 22 is exposed on the frame body when the pull-out lamp 02 extends out of the frame body 01 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com