Air-permeable imitation leather printed fabric and production process thereof

A production process and breathable technology, applied in the field of imitation leather fabrics, can solve the problems of polluting the environment, easy to cause discomfort after wearing for a long time, VOC emission, etc., and achieve the effects of comfortable wearing, good moisture absorption and breathability, and large coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, the water-based bright polyurethane of 40 parts by weight, the water-based dull polyurethane of 60 parts by weight, the silicone leveling agent of 0.3 parts by weight, the polyether defoamer of 0.3 parts by weight, 0.2 parts by weight of the association thickener, 1 part by weight of the polyethylenimine crosslinking agent, and 3 parts by weight of the water-based environmental protection pigment are mixed to prepare the imitation leather slurry.

Embodiment 2

[0037] Embodiment 2, the use of water-based bright polyurethane of 50 parts by weight, the water-based dull polyurethane of 50 parts by weight, the silicone leveling agent of 0.3 parts by weight, the polyether defoamer of 0.3 parts by weight, 0.5 parts by weight of the association thickener, 1 part by weight of the polyethylenimine crosslinking agent, and 5 parts by weight of the water-based environmental protection pigment are mixed to prepare the imitation leather slurry.

Embodiment 3

[0038]Embodiment three, the use of water-based bright polyurethane of 45 parts by weight, water-based dull polyurethane of 55 parts by weight, silicone leveling agent of 0.4 parts by weight, polyether defoamer of 0.5 parts by weight, 0.4 parts by weight of the association thickener, 1 part by weight of the polyethylenimine crosslinking agent, and 4 parts by weight of the water-based environmental protection pigment are mixed to prepare the imitation leather slurry.

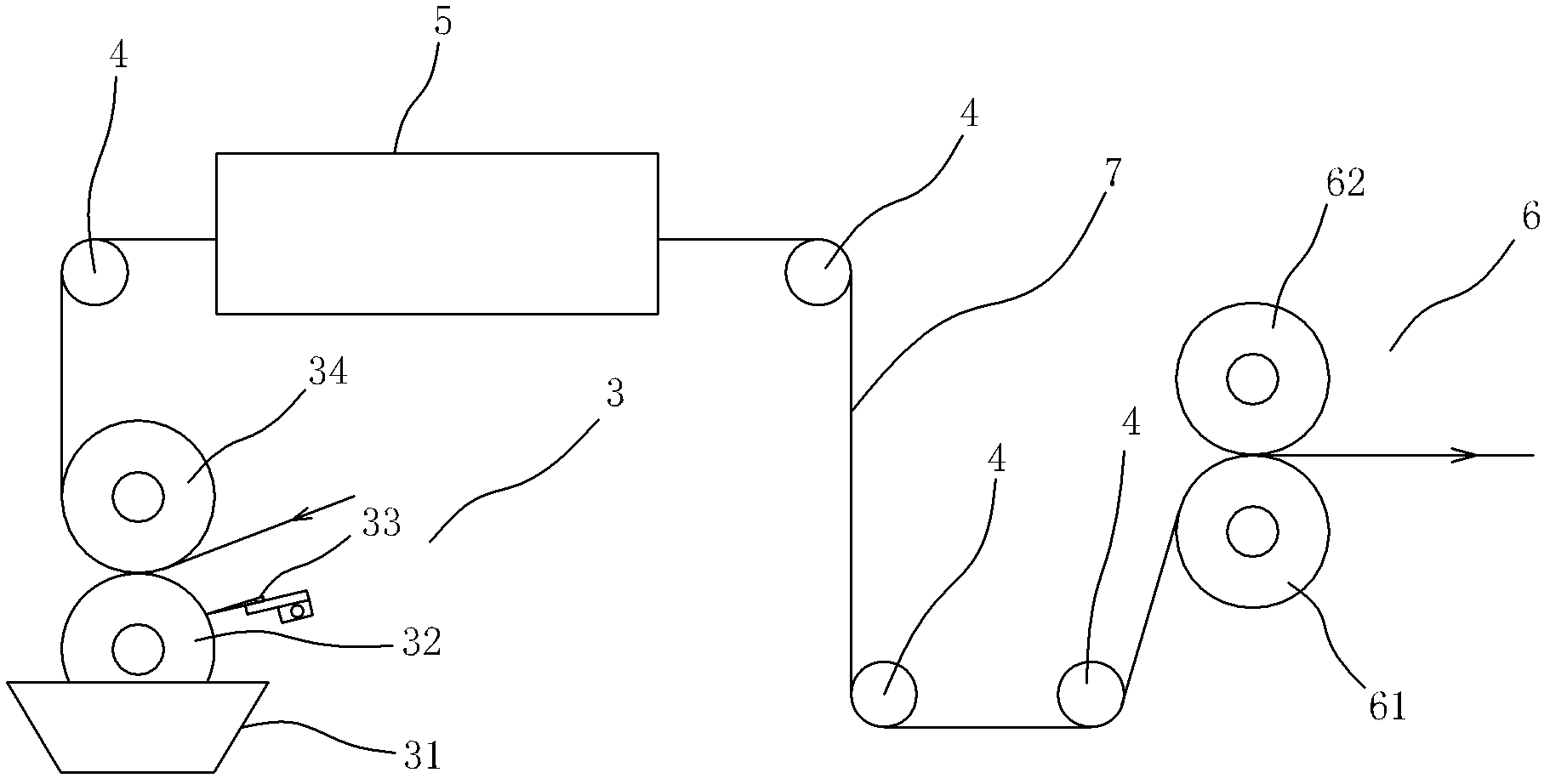

[0039] refer to image 3 Shown, a kind of production system of air-permeable imitation leather printing fabric comprises pretreatment device (not shown in the figure), gravure printing device 3, drying device 5, hot press film-forming device 6, and is used for base cloth 7. The roller conveying device that conveys to the gravure printing device 3, the drying device 5, and the hot-press film forming device 6 in sequence. The gravure printing device 3 includes a hopper 31 for holding the imitation leather slurry, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com