Feeding mechanism of thread rolling lathe

A technology of feeding mechanism and lathe, applied in tangential feeding device, metal processing equipment, tangent device, etc., can solve the problems of manual feeding, jamming, affecting feeding efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

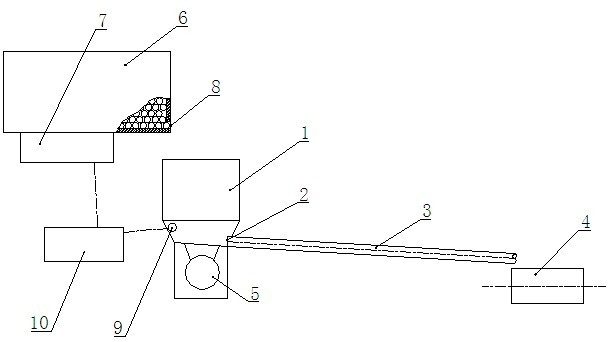

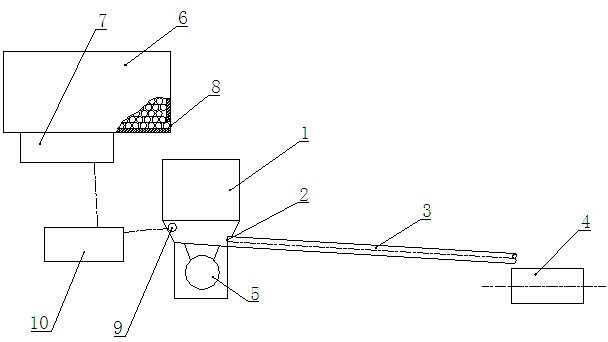

[0007] As shown in the accompanying drawings, the present invention relates to a feeding mechanism of a thread rolling lathe that is not prone to material jamming. The feeding mechanism is placed in front of the thread rolling lathe and includes a primary storage box 1, a discharge port 2, and a discharge pipe 3 , the first vibration motor 5, the secondary material storage box 6, the second vibration motor 7.

[0008] The bottom front end of the above-mentioned primary material storage box 1 is provided with a discharge port 2, and a discharge pipe 3 inclined downward is installed on the discharge port 2, and the outlet of the discharge pipe 3 is located at a pair of thread rolling lathes between round 4. The primary material storage box 1 is fixed with a first vibrating motor 5, and a proximity switch 9 for detecting the height of workpieces in the primary material storage box is installed on the bottom of the primary material storage box 1.

[0009] The secondary storage bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com