Spray cutter device

A technology of cutter and cutting surface, applied in the field of spray measurement, which can solve the problems of mutual interference of disturbance wave wavelengths, inability to accurately measure the wavelength and amplitude of disturbance waves, and interference of experimental results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

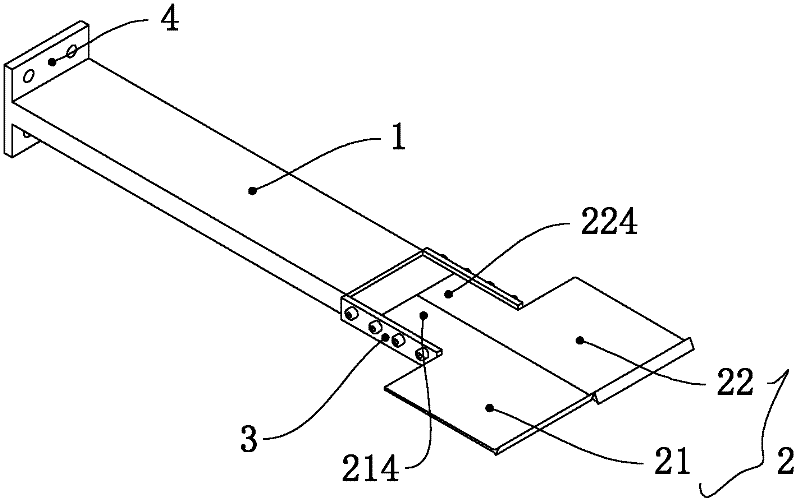

[0024] see figure 1 , a preferred embodiment of the present invention provides a spray cutter device, which is used to cut the conical liquid film rotated into 360° in half to form a liquid film without interference before and after. The spray cutter device includes a bracket 1, Cutter 2 and two connecting blocks 3 connecting the bracket 1 and the cutter 2.

[0025] The support 1 is a long rod, and the first end of the support 1 is connected to the baffle plate 4, and the baffle plate 4 has a plurality of threaded holes, which are connected with other parts by bolts, so that the spray cutter device of the present invention can be fixed.

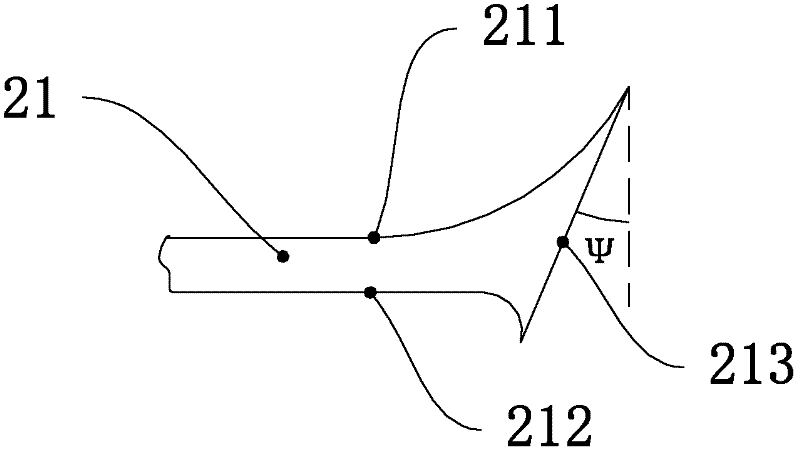

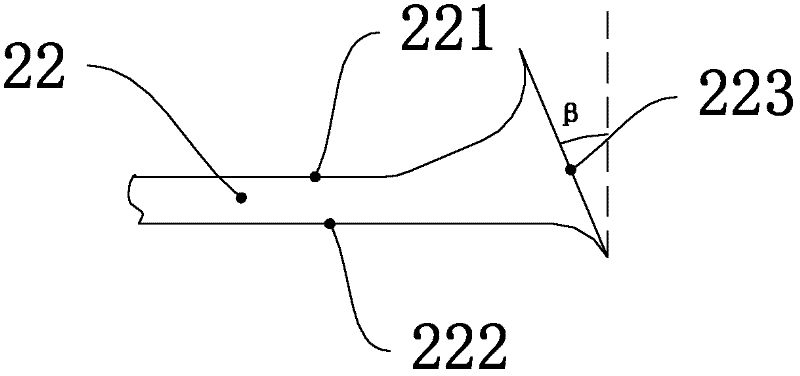

[0026] The cutter 2 is installed on the upper surface of the second end opposite to the first end of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com