Gravure coating apparatus

A coating and gravure technology, which is applied in the device, coating, printing and other directions of coating liquid on the surface, can solve the problem of separation, bubbles K easily flow into the ink storage part, and the coating efficiency of the coating liquid inevitably deteriorates gradually. and other problems, to achieve the effect of improving the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

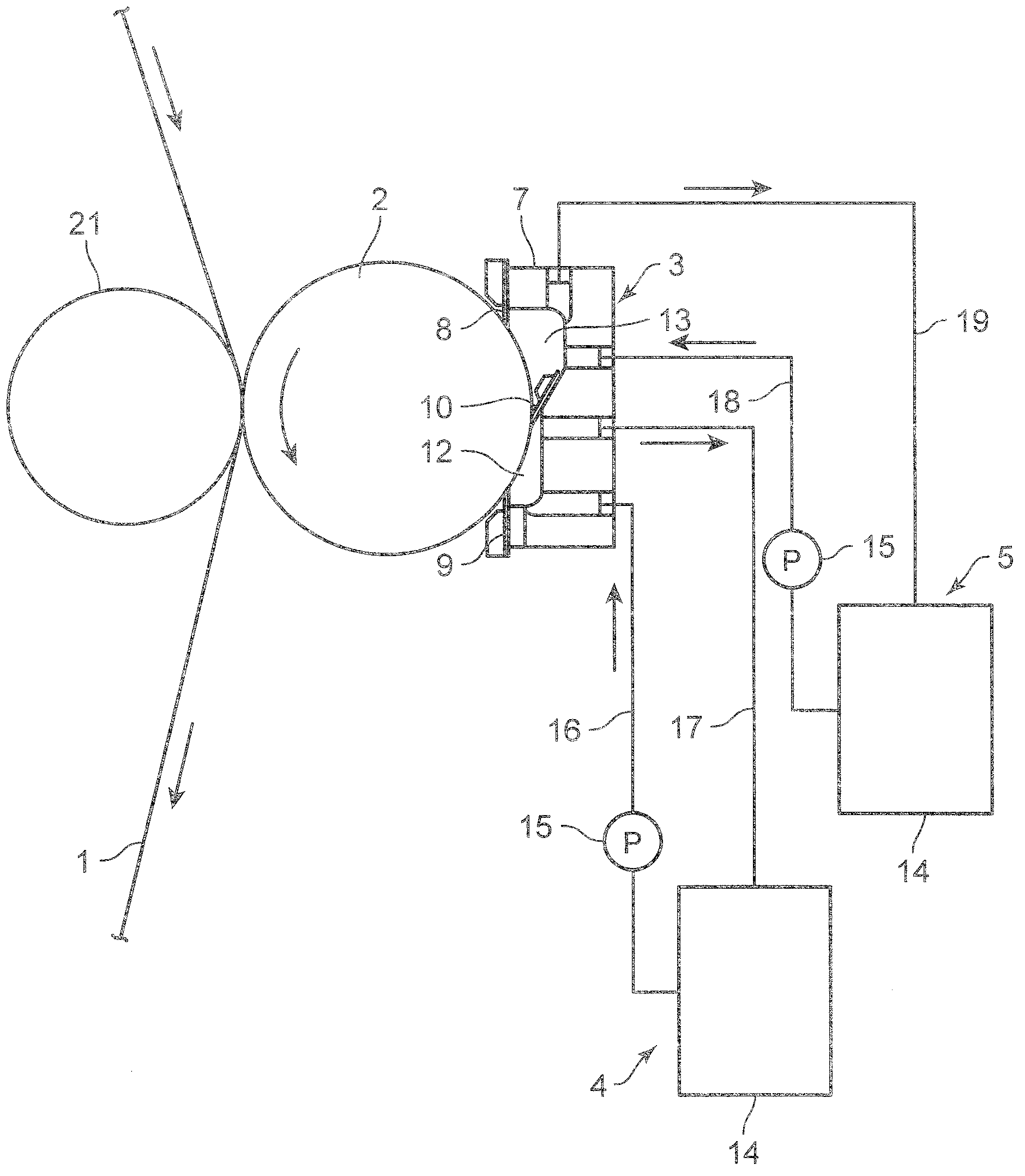

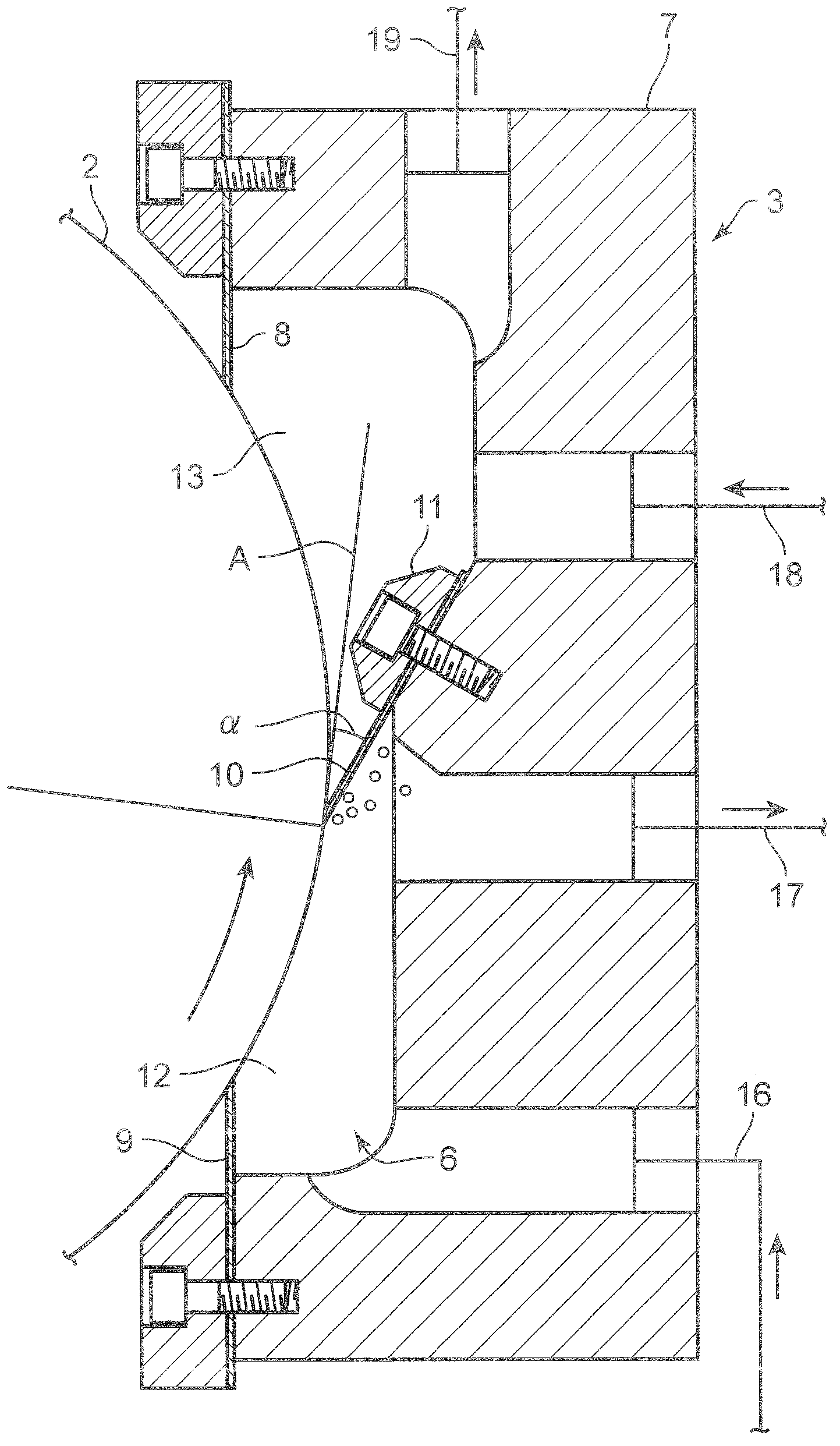

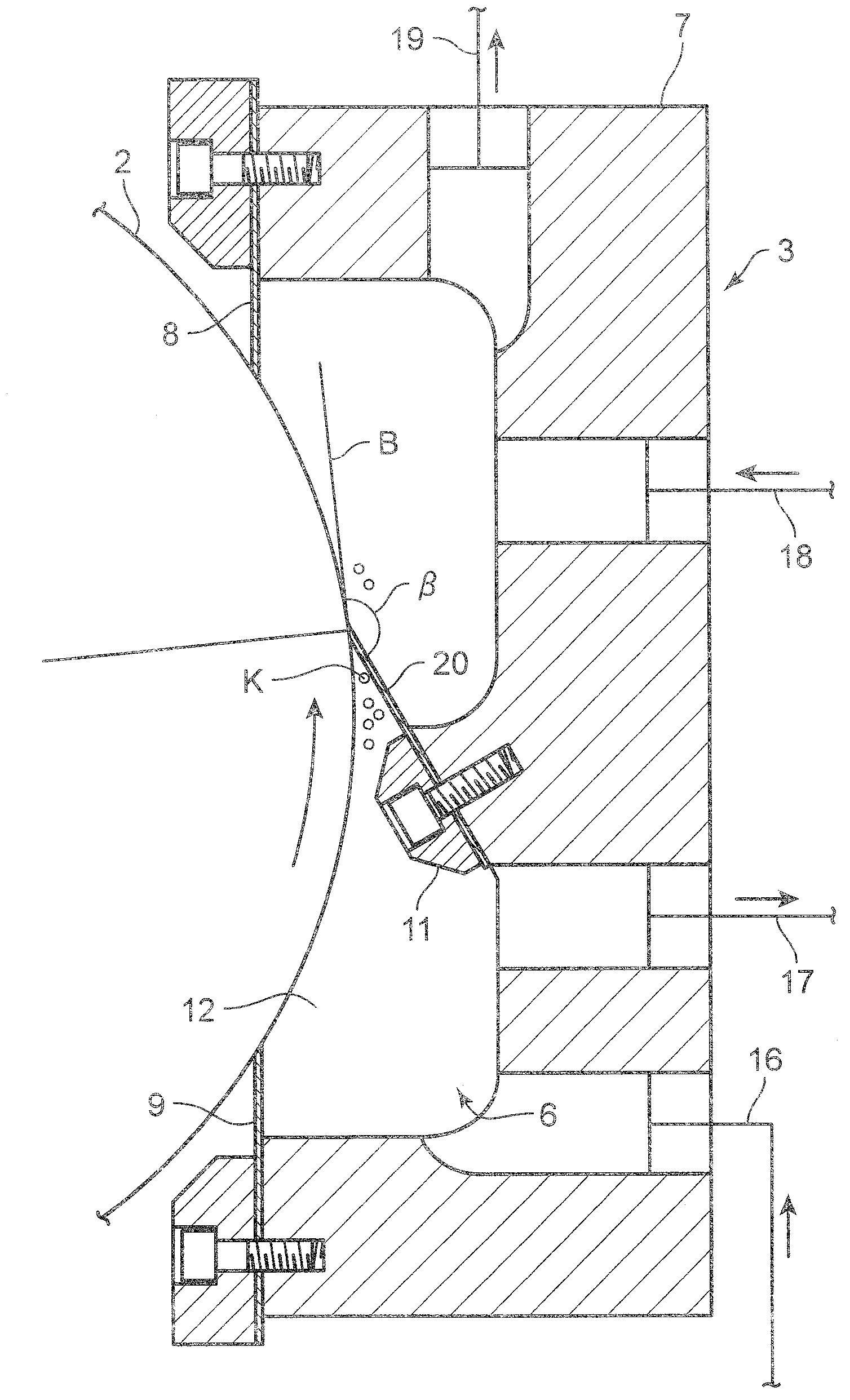

[0044] figure 1 and figure 2 The first embodiment of the gravure coating apparatus of the present invention is shown. This gravure coating device is a device for applying a coating liquid to a sheet-shaped base material 1, and includes a gravure roll arranged on a transport path of the base material 1 to transfer the coating liquid onto the surface of the base material 1. 2; a coating unit 3 for applying a coating liquid to the gravure roll 2 ; and first and second coating liquid supply mechanisms 4 and 5 for supplying the coating liquid to the coating unit 3 .

[0045] The substrate 1 is introduced between the above-mentioned gravure roll 2 and the support roll 21 disposed opposite thereto, the base material 1 is conveyed from above to below, and the above-mentioned gravure roll 2 is rotationally driven in a direction opposite to the conveyance direction of the substrate 1 , and at the same time, the gravure roll 2 is brought into contact with the substrate 1 to apply the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com