Automatic positioning discharge system

An automatic positioning and material technology, which is applied in the direction of trolley cranes, load hanging components, cranes, etc., can solve the problems of low work efficiency and high labor intensity of operators, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

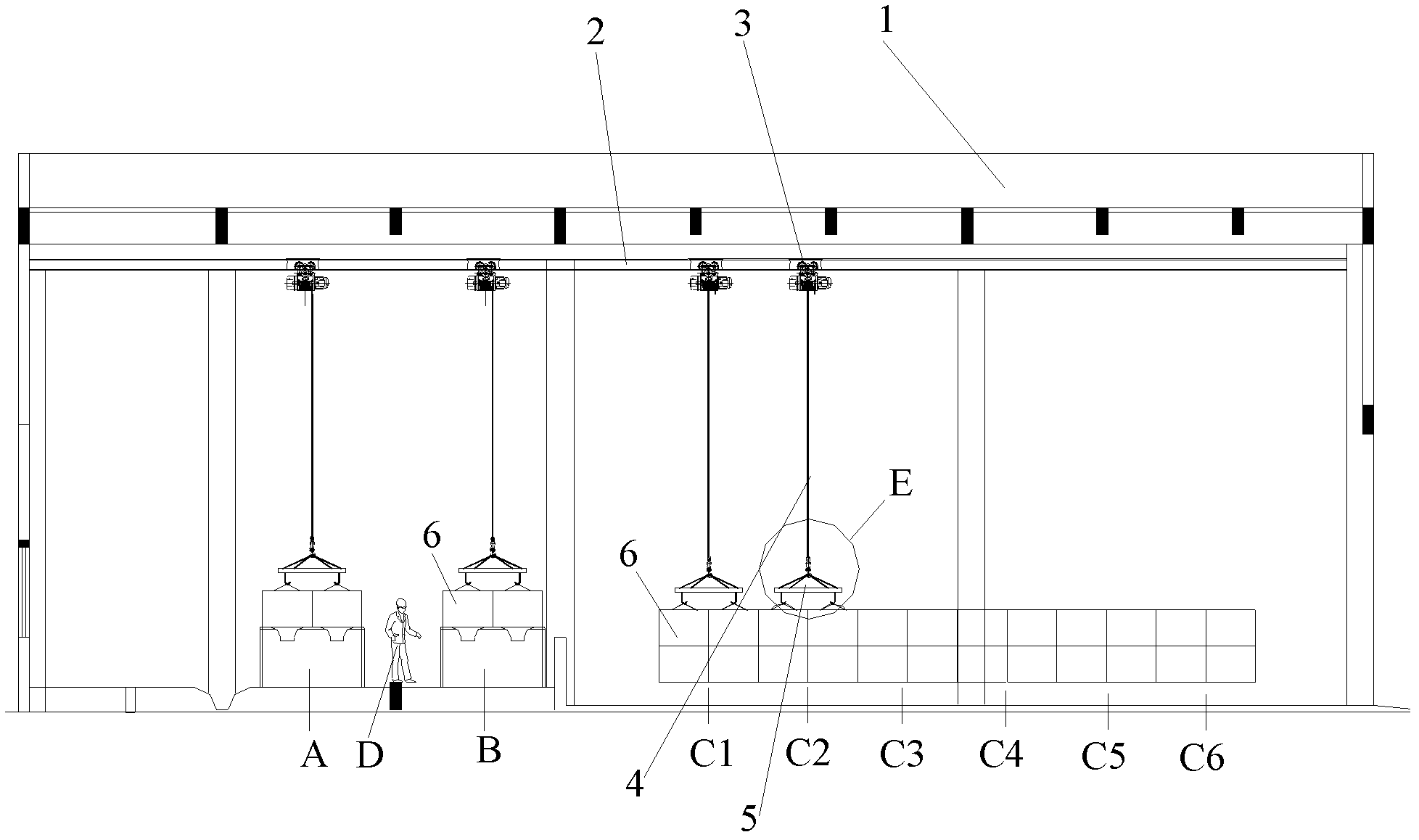

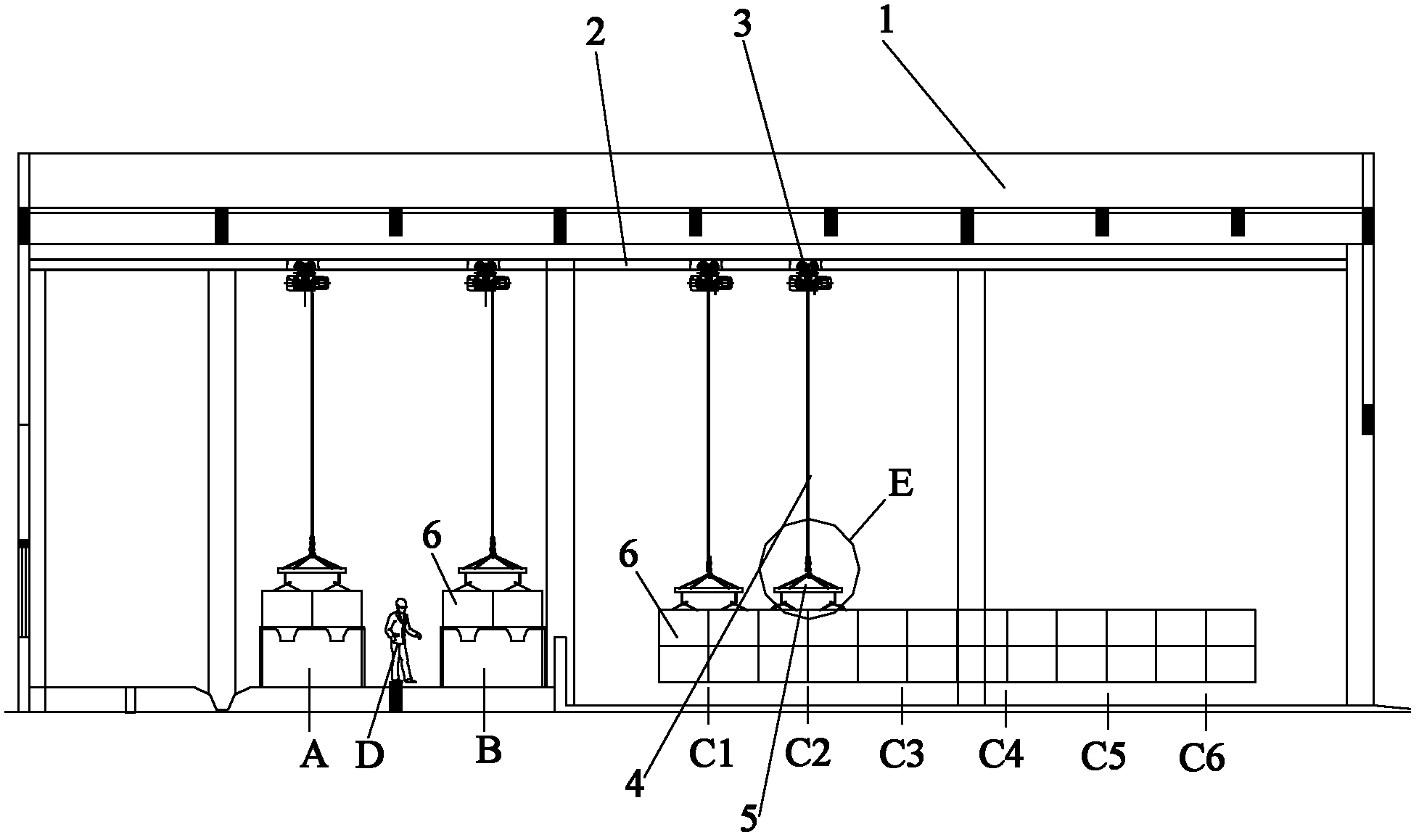

[0032] see figure 1 , the automatic positioning and unloading system in this embodiment includes a support 1 placed on the ground, a moving rail 2 arranged on the support 1, an electric hoist 3 arranged on the moving rail 2 and capable of moving along the moving rail, and an electric hoist 3 The connected steel wire rope 4, the material grasping mechanism 5 for grasping the material, and the stroke control mechanism (not shown in the figure) for controlling the electric hoist to move according to the preset stroke.

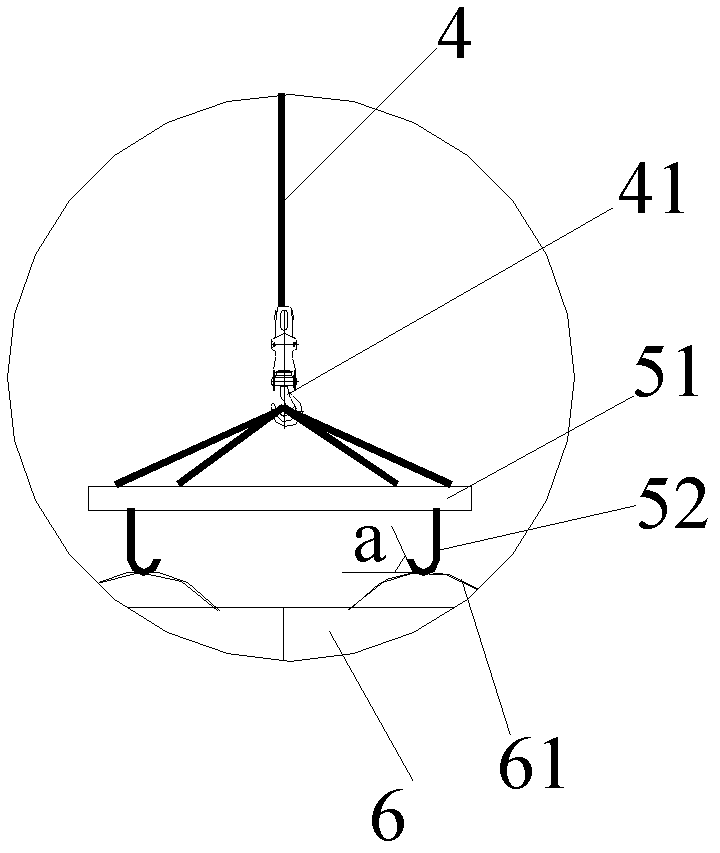

[0033] see figure 2 The material grabbing mechanism 5 includes a hanger 51 connected to the hook 41 of the steel wire rope 4 and a grapple 52 connected under the hanger 51. A plurality of grapples 52 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com