Tower crane capable of transporting, loading and unloading

A technology of tower crane and tower body is applied in the field of industrial tower cranes, which can solve the problems of time consumption, the tower crane occupies a considerable amount, and the tower crane cannot do any movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

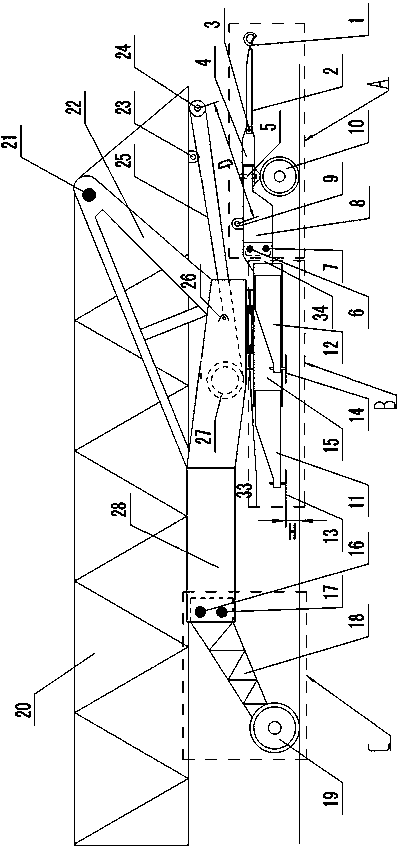

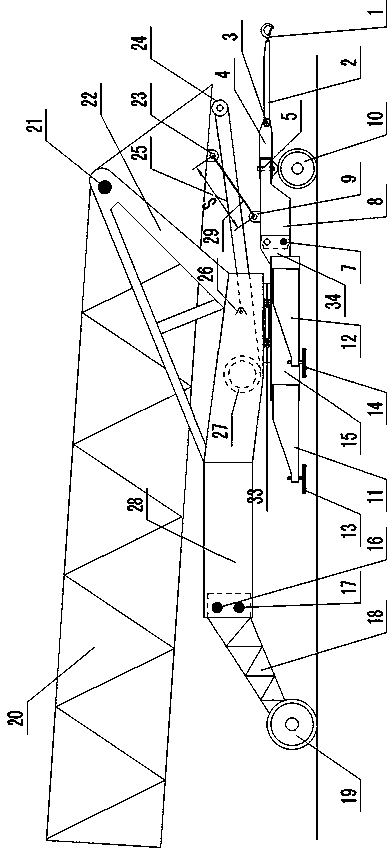

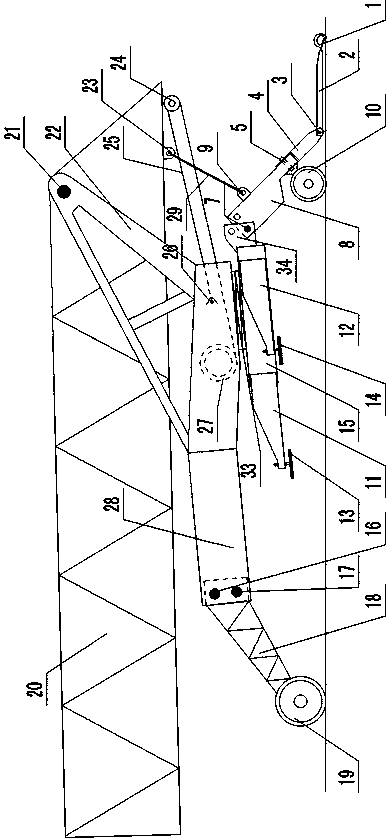

[0020] Such as Figure 1~Figure 7 As shown, this embodiment discloses a tower crane that can be transported and loaded and unloaded, and a method for getting on and off the vehicle in the overall transport state. Wherein comprise front vehicle A, base structure B, rear vehicle C, tower body 20 and stay cable 29.

[0021] Such as figure 1 As shown, the tower crane is in a folded state during overall transportation, the tower body 20 is lying on the slewing platform 28, the bottom side is movably connected with the diagonal brace 22 through the rotating pin 21, and the triangular structure at the tail extends out of the diagonal brace . The bottom inside the tower body is provided with an upper ear plate 23 and a vertical tower pulley 24 in sequence along the horizontal direction. The middle part of the turntable is also provided with a winch 27 and a fixed lug 26 , and the bottom is connected with the underframe 15 through a turn support 33 . The output end of the winch 27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com