Multifunctional integrated machine of electrolytic manganese metal cathode plate and automatic plugging plate

A technology for electrolysis of manganese metal and cathode plates, which is applied in the electrolysis process, electrolysis components, photography process, etc., can solve the problems of potential safety hazards for operators, damage to baking furnace parts, and increase energy consumption of the baking furnace, so as to reduce the number of people The effect of improving work and production environment and improving automation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

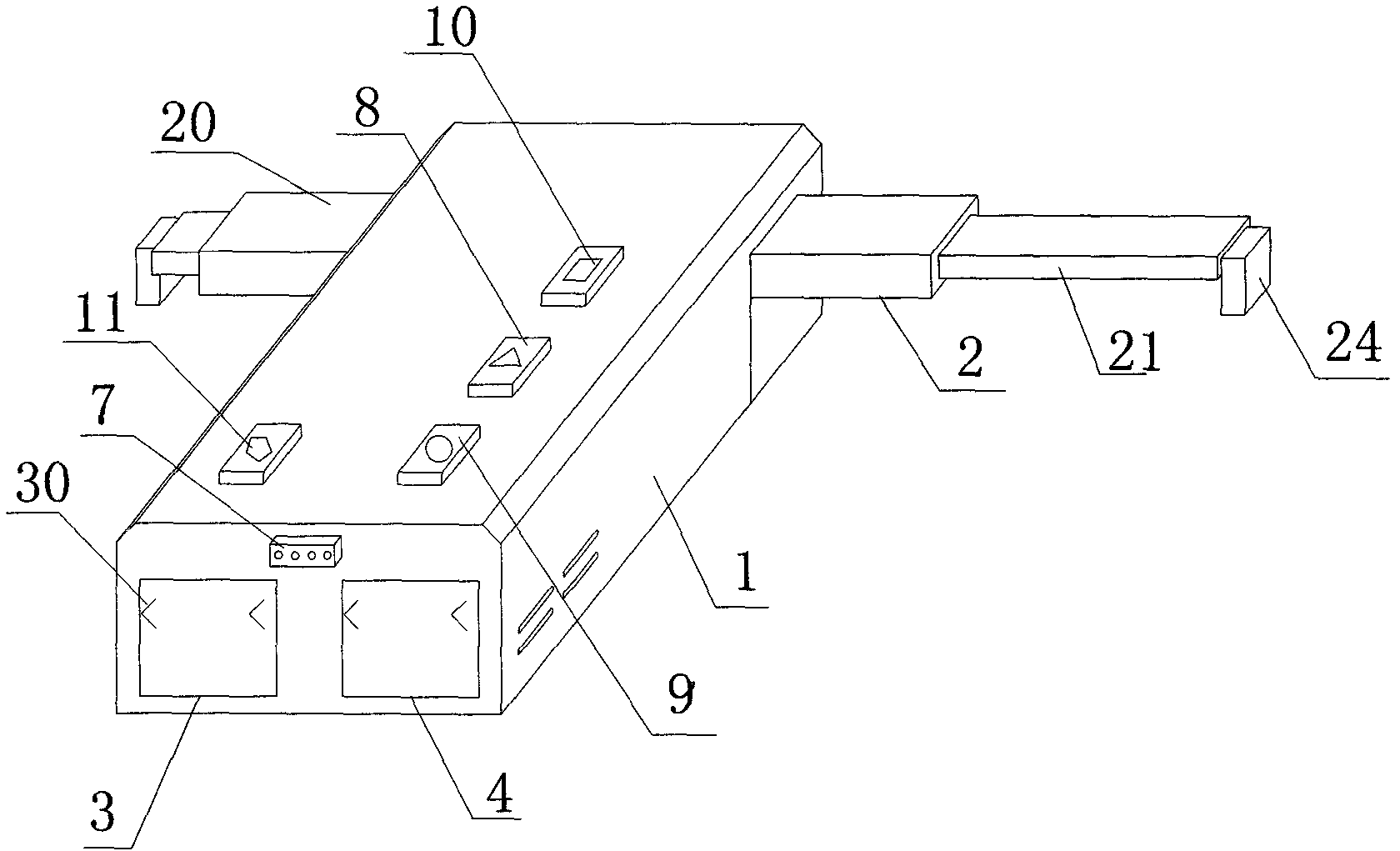

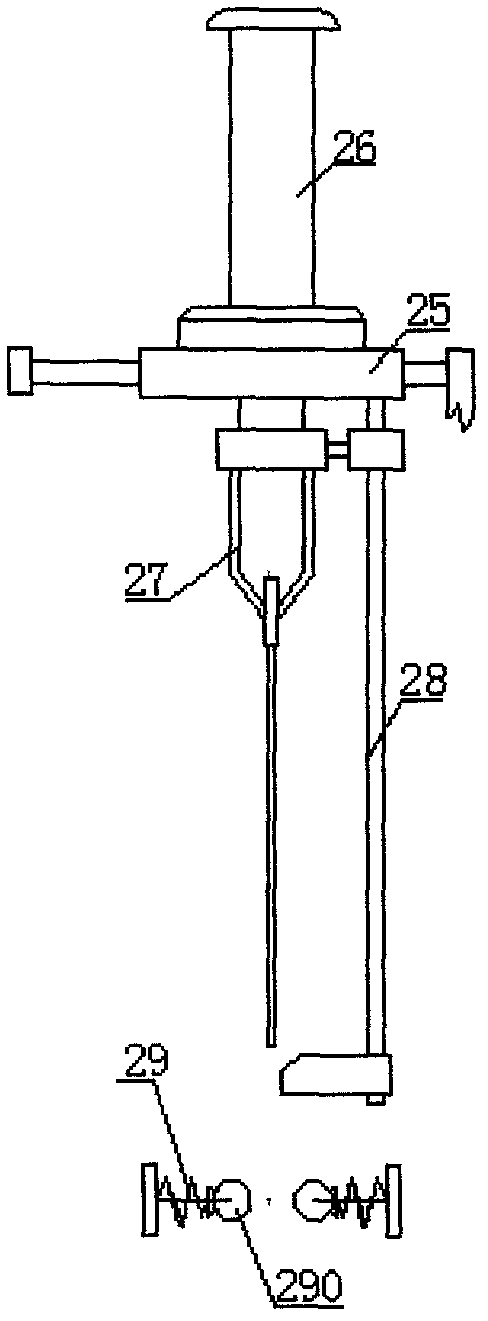

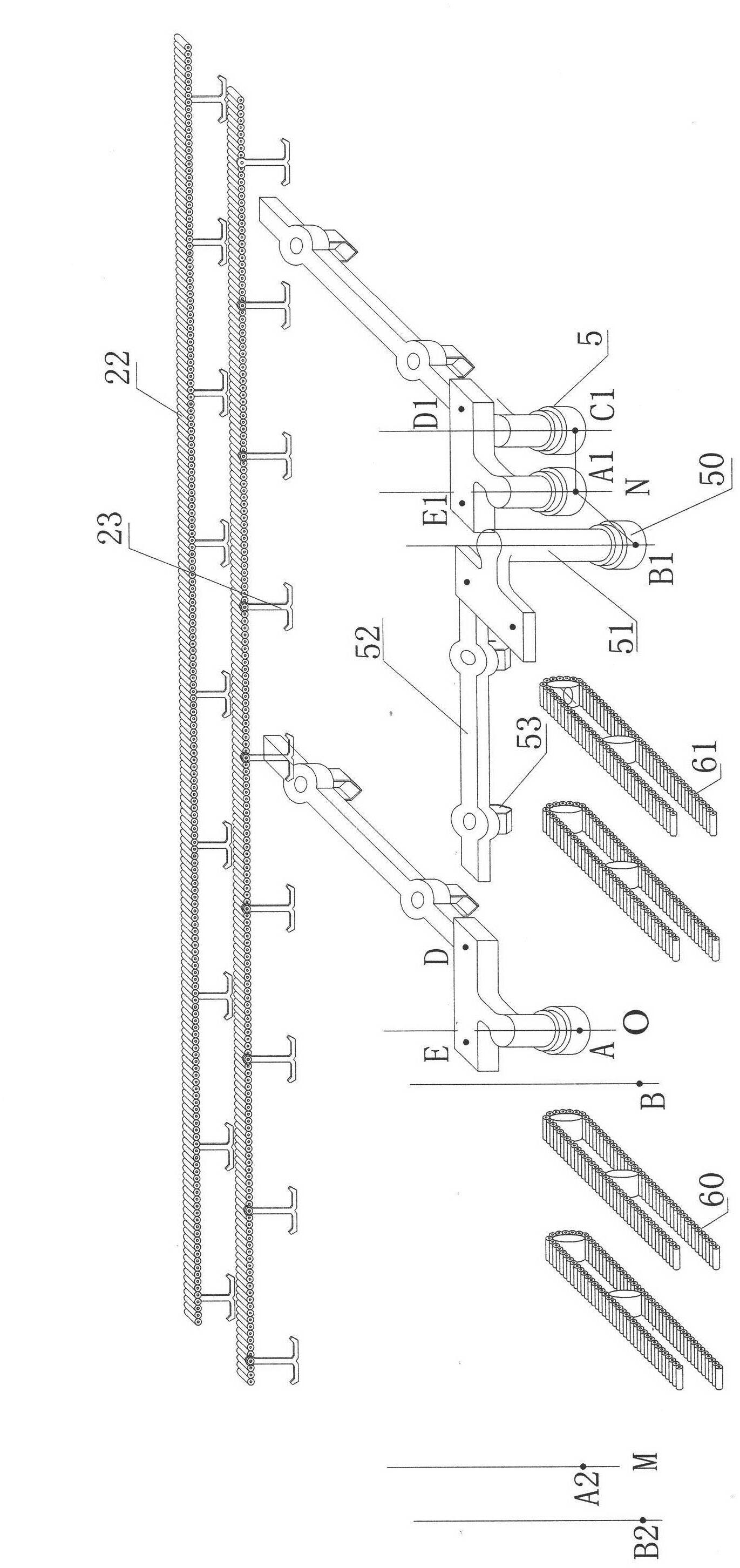

[0023] In this embodiment, refer to Figure 1 to Figure 3 As shown, the electrolytic metal manganese cathode plate automatic insertion and removal board multifunctional machine is used in the electrolytic metal manganese production enterprise to complete the automatic insertion, collection, passivation, cleaning, purging, and lighting of the cathode plate in the electrolysis process. Large-scale automation equipment for chemical and other processes. The electrolytic metal manganese cathode plate automatic inserting and removing plate multifunctional machine includes a walking body 1, and a body boom 2 arranged at one end of the walking body 1 for inserting and removing the cathode plate, and an inserting arm arranged on the other end of the walking body 1. The board entrance 3 and the board exit 4, and the shift fork coupling 5 arranged in the walking body 1 on the side of the body boom 2 for inserting and removing the board, and the cathode plate conveying chain arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com