Abrasion resistance testing device

A testing device and wear-resistant technology, which can be used in measuring devices, testing wear-resistance, instruments, etc., and can solve problems such as lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

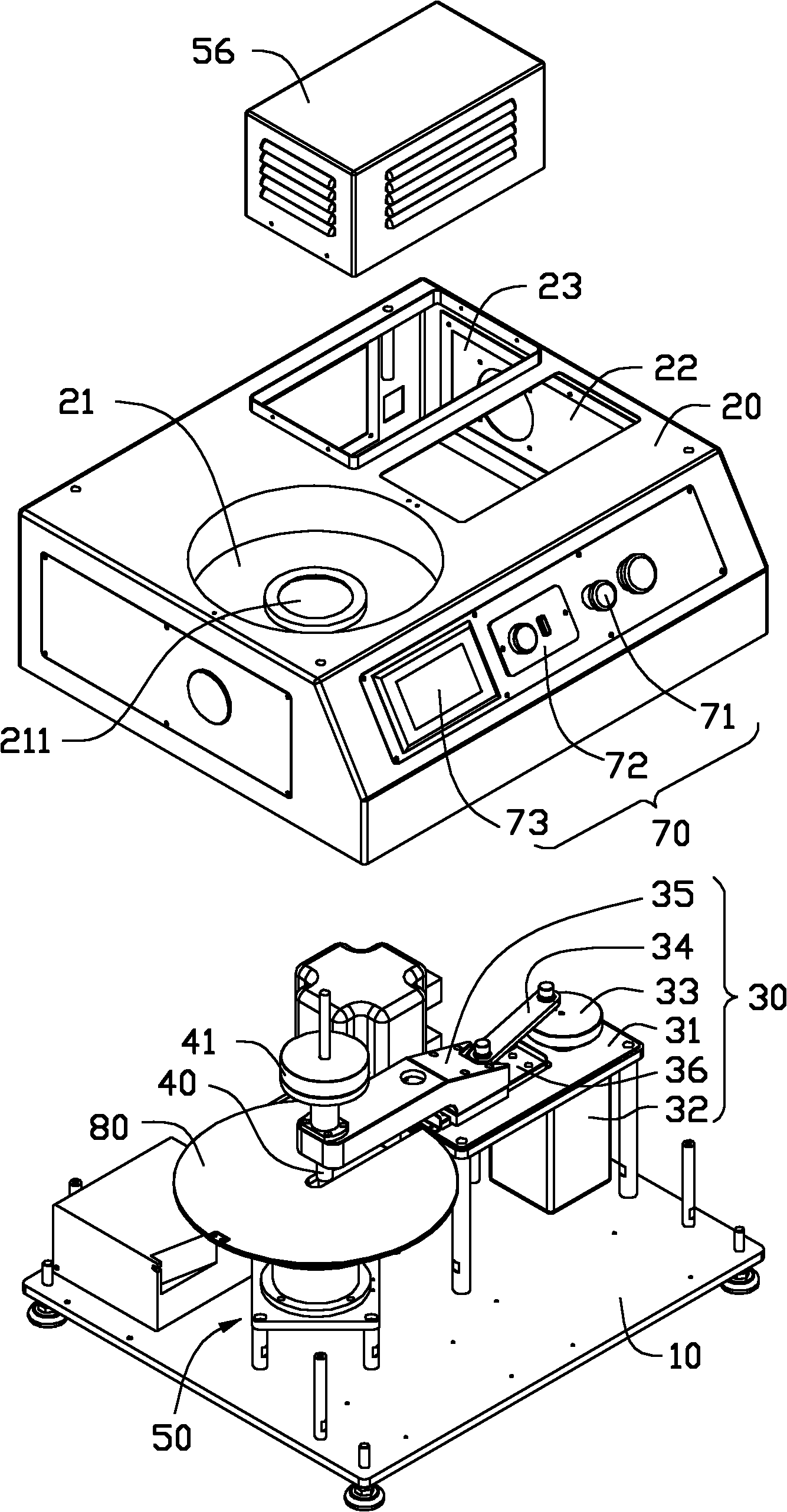

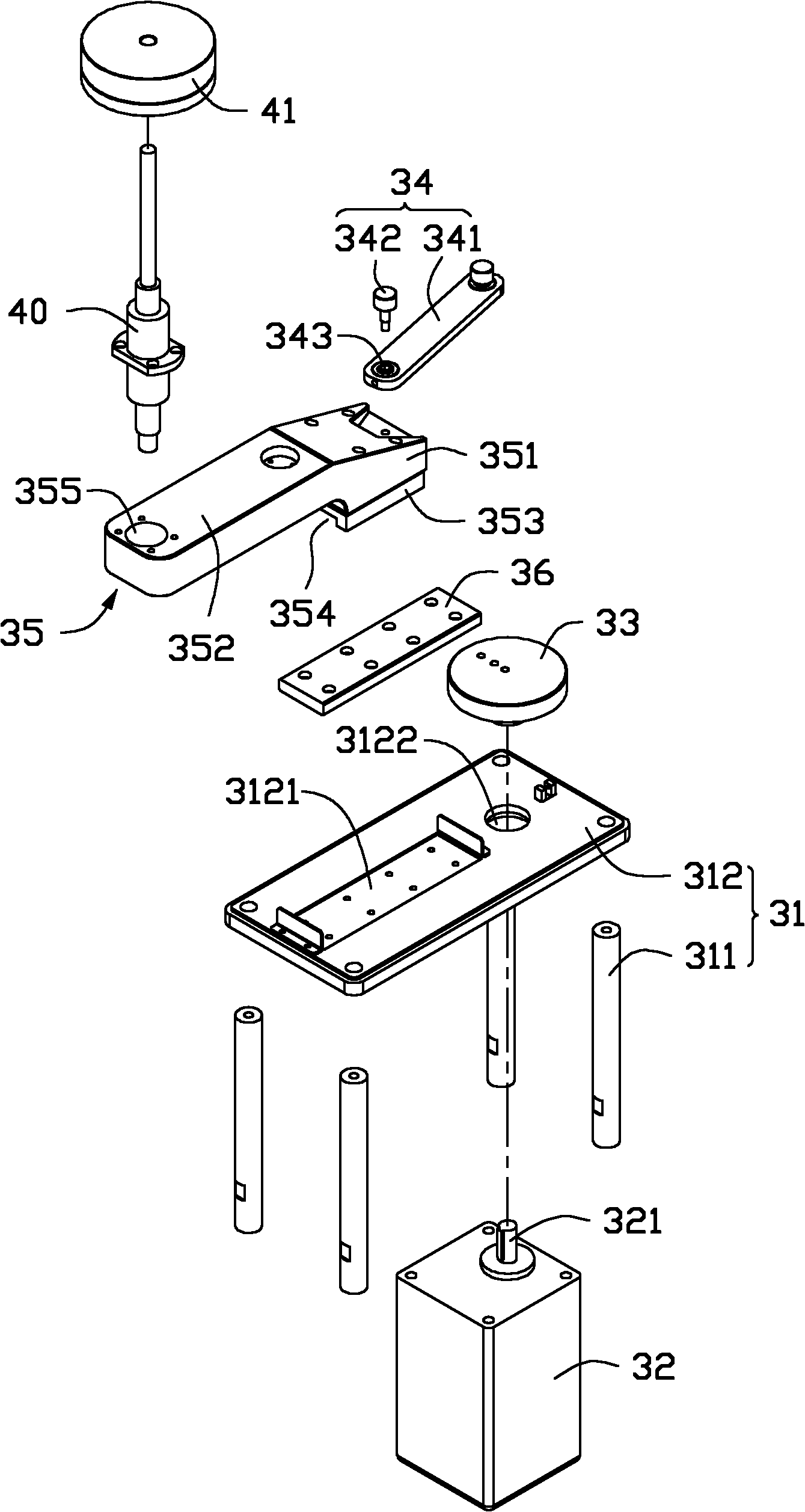

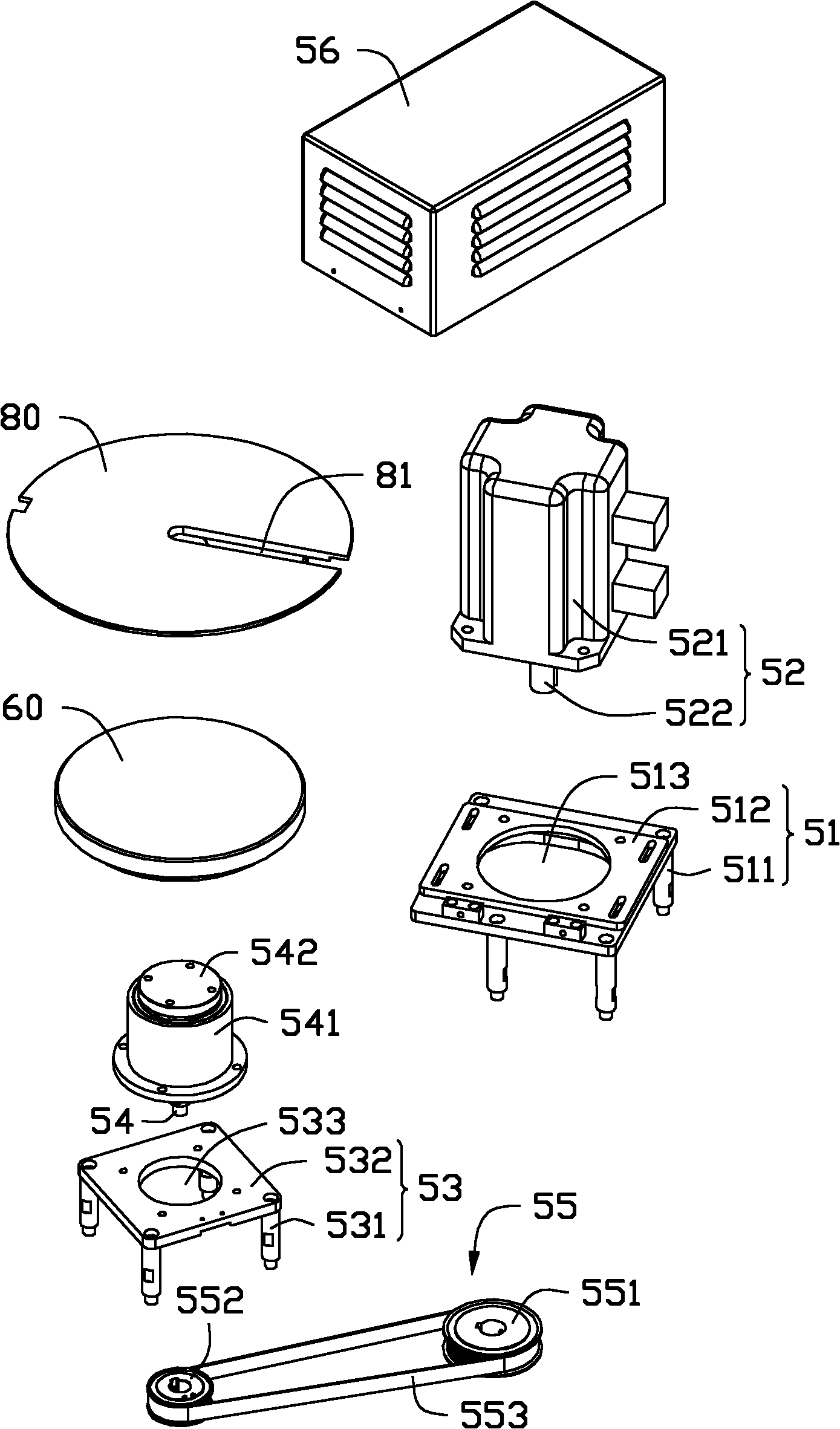

[0014] see figure 1 A preferred embodiment of the present invention provides an abrasion resistance testing device 100 for testing the abrasion resistance of sandpaper. This abrasion resistance testing device 100 comprises base plate 10, outer cover 20, sliding mechanism 30, pressing member 40, rotating mechanism 50, grinding disc 60 (see image 3 ) and the control assembly 70. The pressing member 40 is installed on the sliding mechanism 30, and slides reciprocally under the drive of the sliding mechanism 30. The grinding disc 60 is installed on the rotating mechanism 50, and the sandpaper to be tested is placed on it. Driven by the rotating mechanism 50 , the sandpaper to be tested is driven to rotate and rub against the pressing member 40 that slides back and forth.

[0015] The outer cover 20 is disposed on the bottom plate 10 and together with the bottom plate 10 forms a closed accommodating space (not shown). The top of the cover 20 defines a circular groove 21 and two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com