Wear resistance detection device for warp knitting cloth

A detection device and wear resistance technology, which is applied in the field of warp knitted fabric detection, can solve the problems of narrow application range and achieve the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

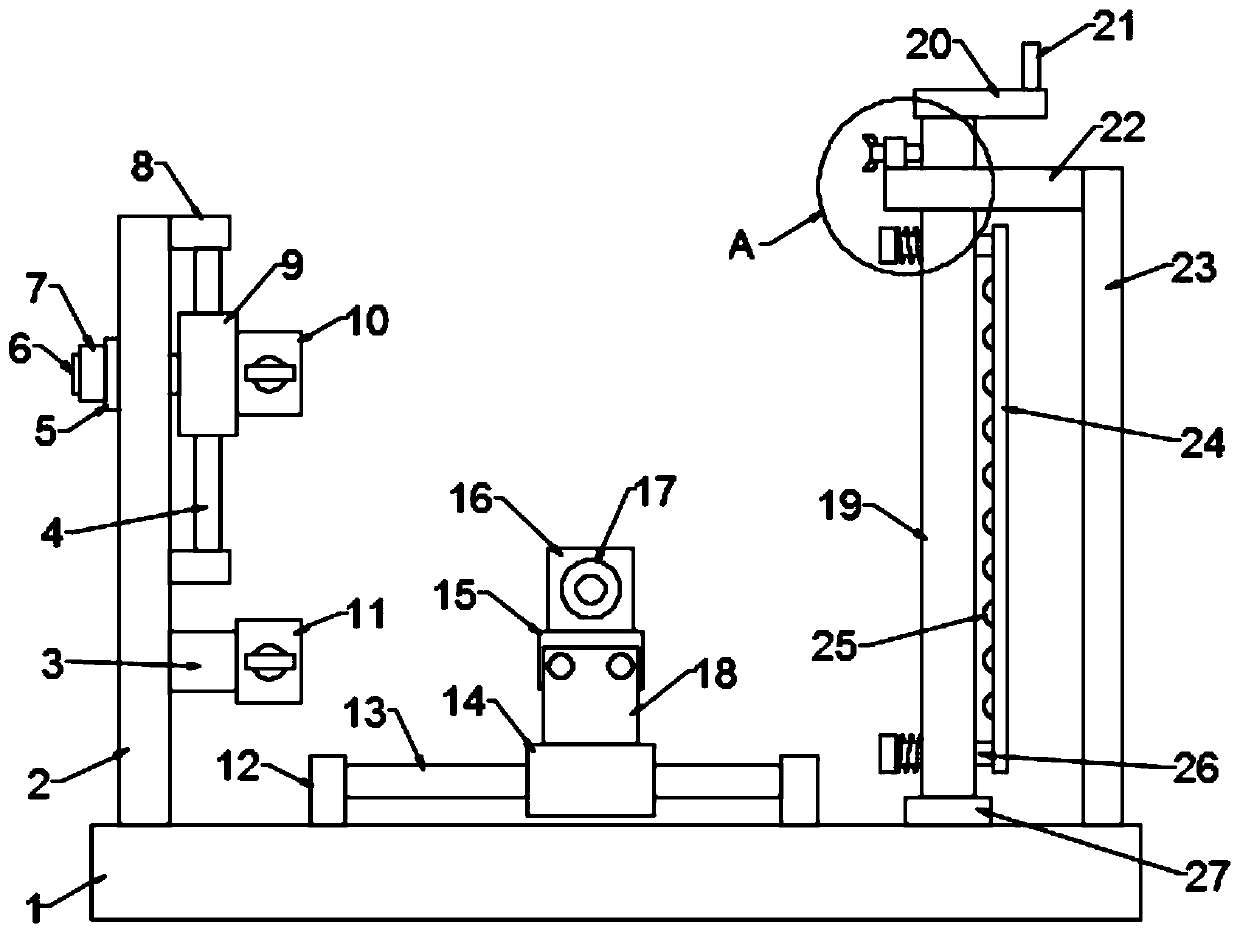

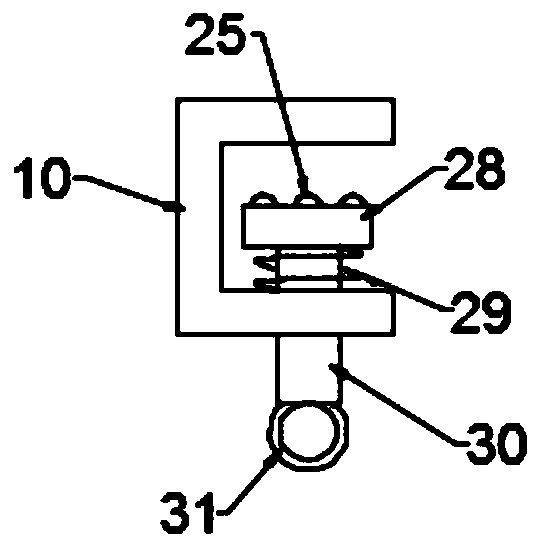

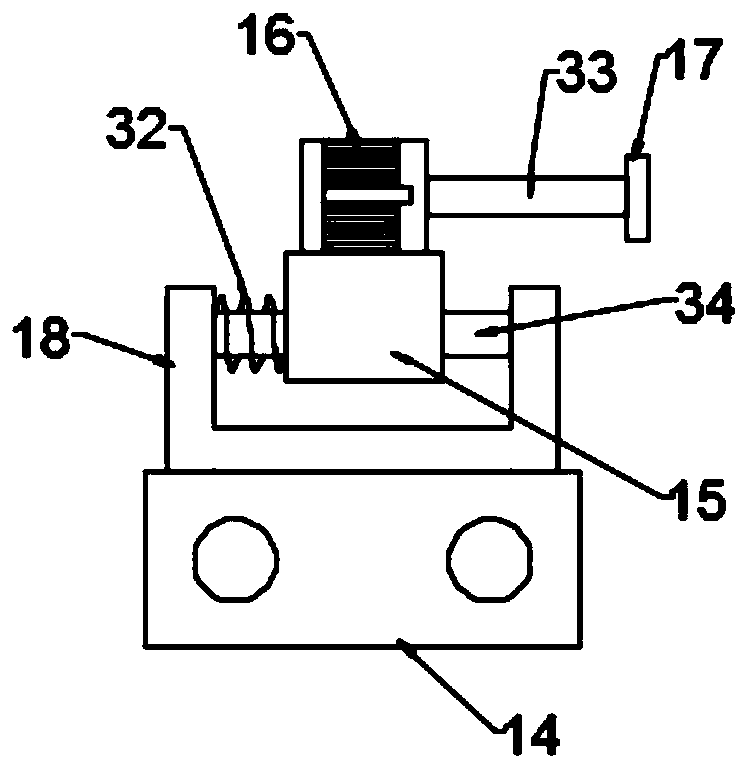

[0030] see Figure 1-5 , in the embodiment of the present invention, a kind of wear resistance detection device of warp knitted cloth comprises base plate 1 and motor 16, and the output shaft of motor 16 is connected with rotating shaft 33, and grinding disc 17 is installed on rotating shaft 33; A vertical plate 2 and a column 23 are fixed, a fixed block 3 is fixed on the vertical plate 2, a second U-shaped seat 11 is installed on the fixed block 3, and a first U-shaped seat 10 is provided on the upper side of the second U-shaped seat 11, Both the first U-shaped seat 10 and the second U-shaped seat 11 are slidably provided with a fourth slide bar 30, and the two ends of the fourth slide bar 30 are respectively connected with a pull ring 31 and a pressure block 28, and on the fourth slide bar 30 The first spring 29 is sleeved, and the vertical plate 2 is provided with an adjustment assembly for adjusting the height of the first U-shaped seat 10;

[0031] The top of the column ...

Embodiment 2

[0043] see Figure 6 , in the embodiment of the present invention, a warp knitted cloth wear resistance detection device is different from embodiment 1 in that an inner rod 40 and an outer cylinder 42 are provided between the mounting seat 18 and the slider 14, and the inner rod 40 is slidably connected with the inner wall of the outer cylinder 42, and the locking bolt 41 for locking the inner rod 40 is threadedly installed on the outer cylinder 42; through the sliding fit between the inner rod 40 and the outer cylinder 42, the mounting seat 18 can be raised and lowered to make the grinding disc 17 At different heights, it is possible to inspect areas of different heights on the warp knitted fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com