Yarn abrasion resistance testing device and abrasion resistance testing method

A testing device and wear resistance technology, applied in the direction of testing wear resistance, etc., can solve the problems of not being able to truly reflect the degree of friction in the weaving process, not being able to fully simulate the wear situation, and reducing the friction between yarns and yarns, etc., to achieve a simple structure , Simple installation, and the effect of avoiding detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in detail below:

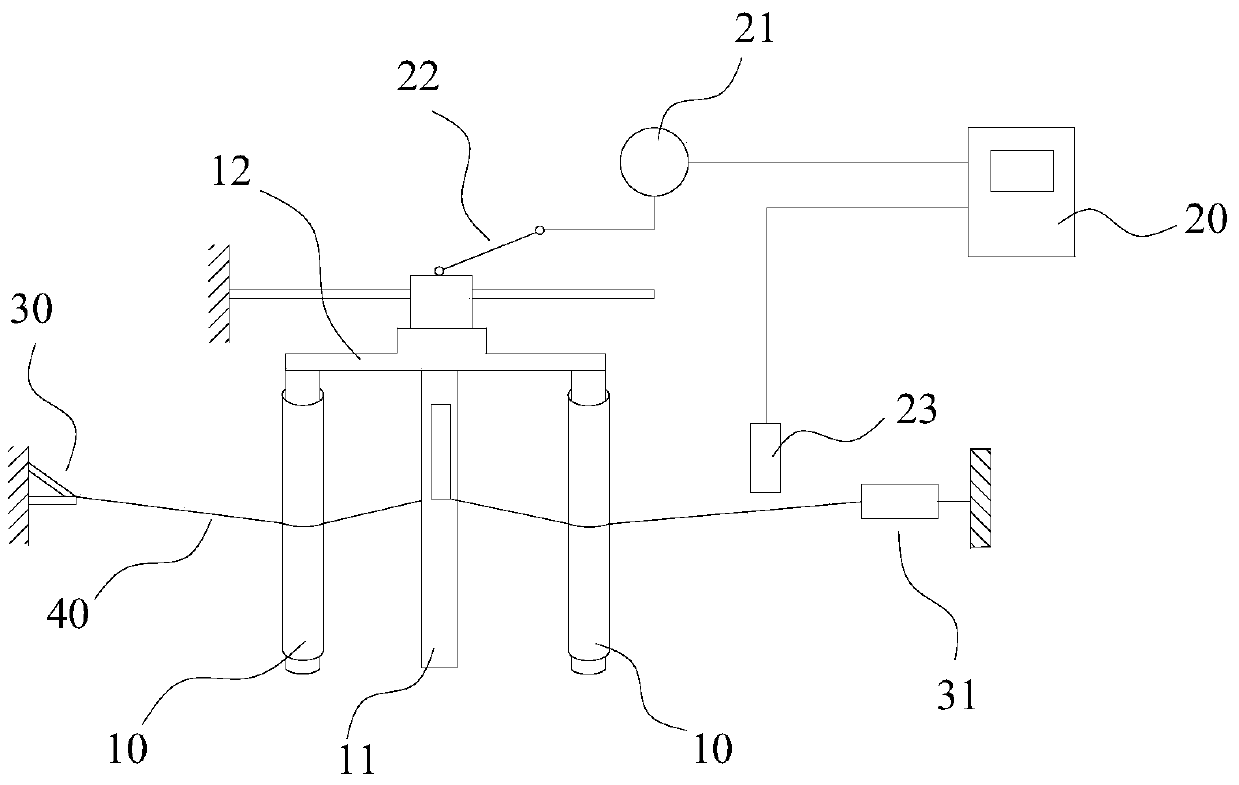

[0033] Such as Figure 1 to Figure 5 Shown, a kind of yarn abrasion resistance testing device comprises friction bar 10, heddle 11, the connecting rod 12 that connects friction bar 10 and heald 44, and heddle 11 has the heald eye for passing yarn 40 111, drive the power device 21 and the transmission mechanism 22 for reciprocating motion of the friction rod 10, the heddle 11, and the connecting rod 12, the yarn breakage sensor 23 for detecting the breakage of the yarn 40, and the counter 20 for recording the friction times when the yarn 40 breaks.

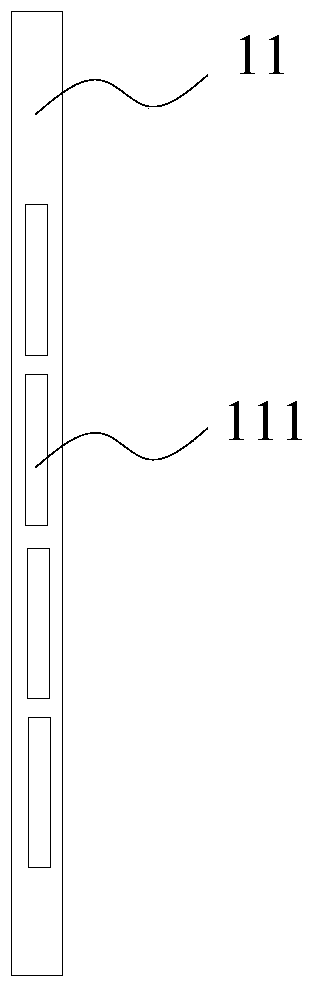

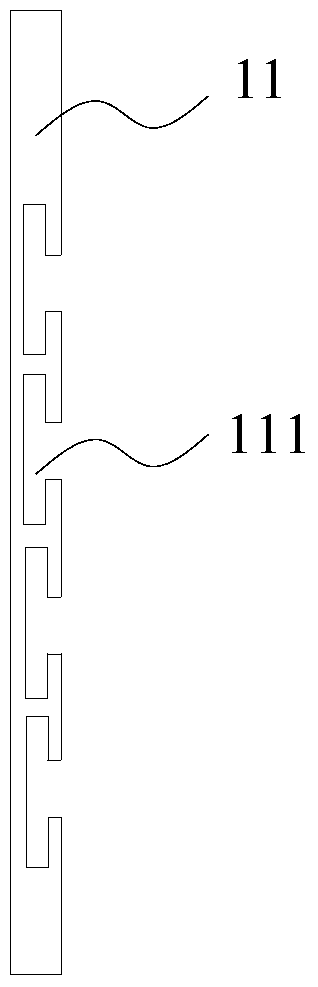

[0034] Wherein, there are multiple heddles 11, the heald eyes are elongated, and the heald eyes are in a closed-loop state or a semi-closed-loop state. The plurality of heddle eyes 111 are arranged along the axial direction of the heddle 11 . The heddle eye 111 is in a closed loop state. The heald eye 111 is in a semi-closed loop state, the opening dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com