An automatic tester for wear resistance and tightness of sealing rings

A sealing ring and sealing technology, applied in the field of sealing ring wear resistance and sealing automatic detector, can solve the problems of inability to detect the sealing ring wear resistance, high detection cost, complex structure, etc., achieve simple structure, improve comprehensive The effect of reducing the consumption of air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the embodiments.

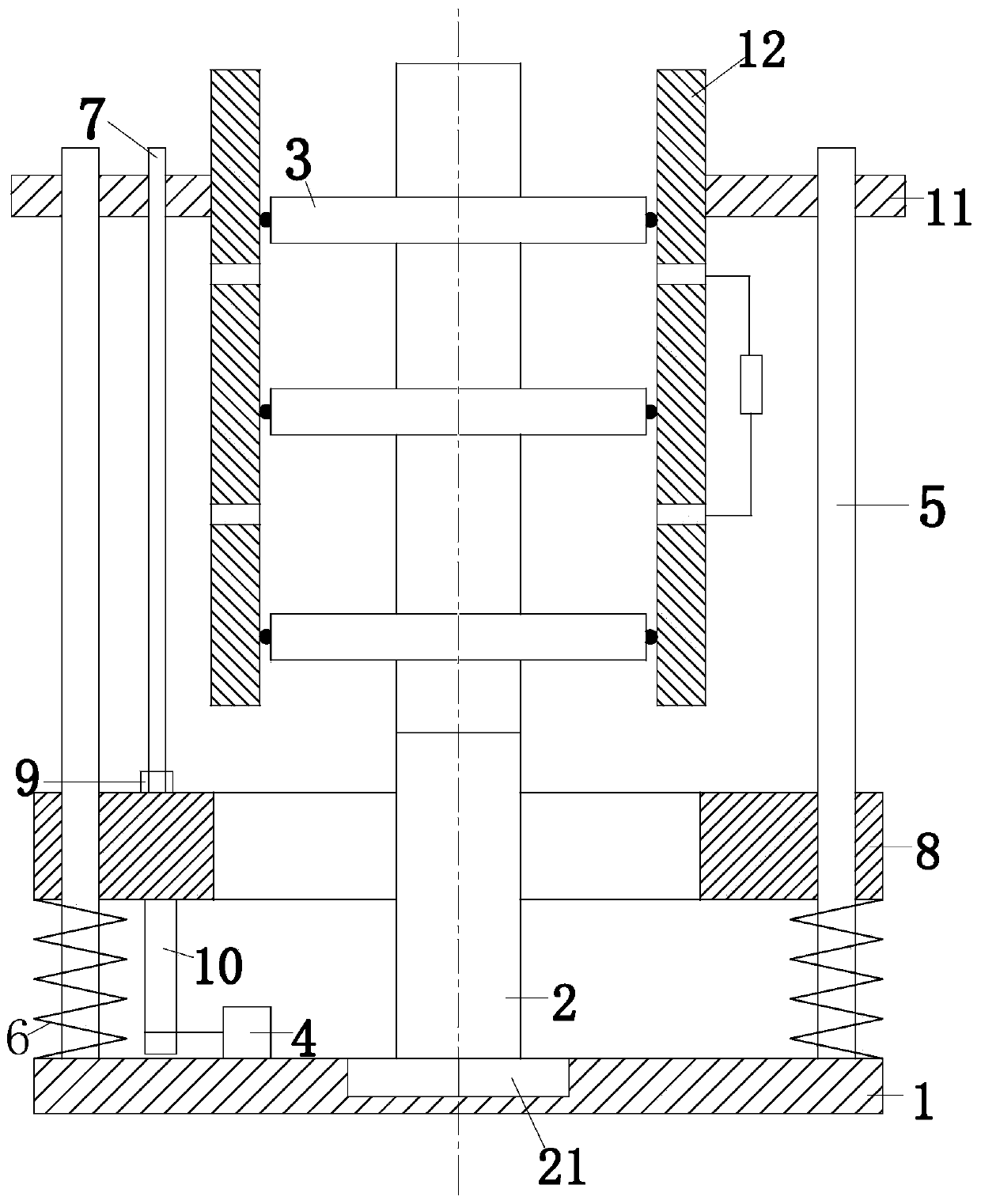

[0021] Such as figure 1 As shown, a kind of rubber abrasion resistance and tightness automatic tester of the present invention comprises circular base 1, mounting table 2, mounting plate 3, vibrating motor 4, guide post 5, vibrating spring 6, screw mandrel 7, Vibration base 8, connecting motor 9, cam 10, bracket 11 and sleeve 12; the circular base 1 is disc-shaped, the center of the circular base 1 is provided with a mounting platform 2, and the upper end of the mounting platform 2 is equipped with end-to-end There are a plurality of mounting discs 3, and the mounting discs 3 are used to install the sealing ring; two vertical guide posts 5 are symmetrically arranged on both sides of the circular base 1, and a vibration spring 6 is installed on the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com