Metal melt diffusion device

A metal melt and equipment technology, applied in the field of metal melt diffusion equipment, can solve problems such as large differences, and achieve the effects of removing systematic errors, accurate and reasonable diffusion coefficient measurement, and reducing residual temperature diffusion time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

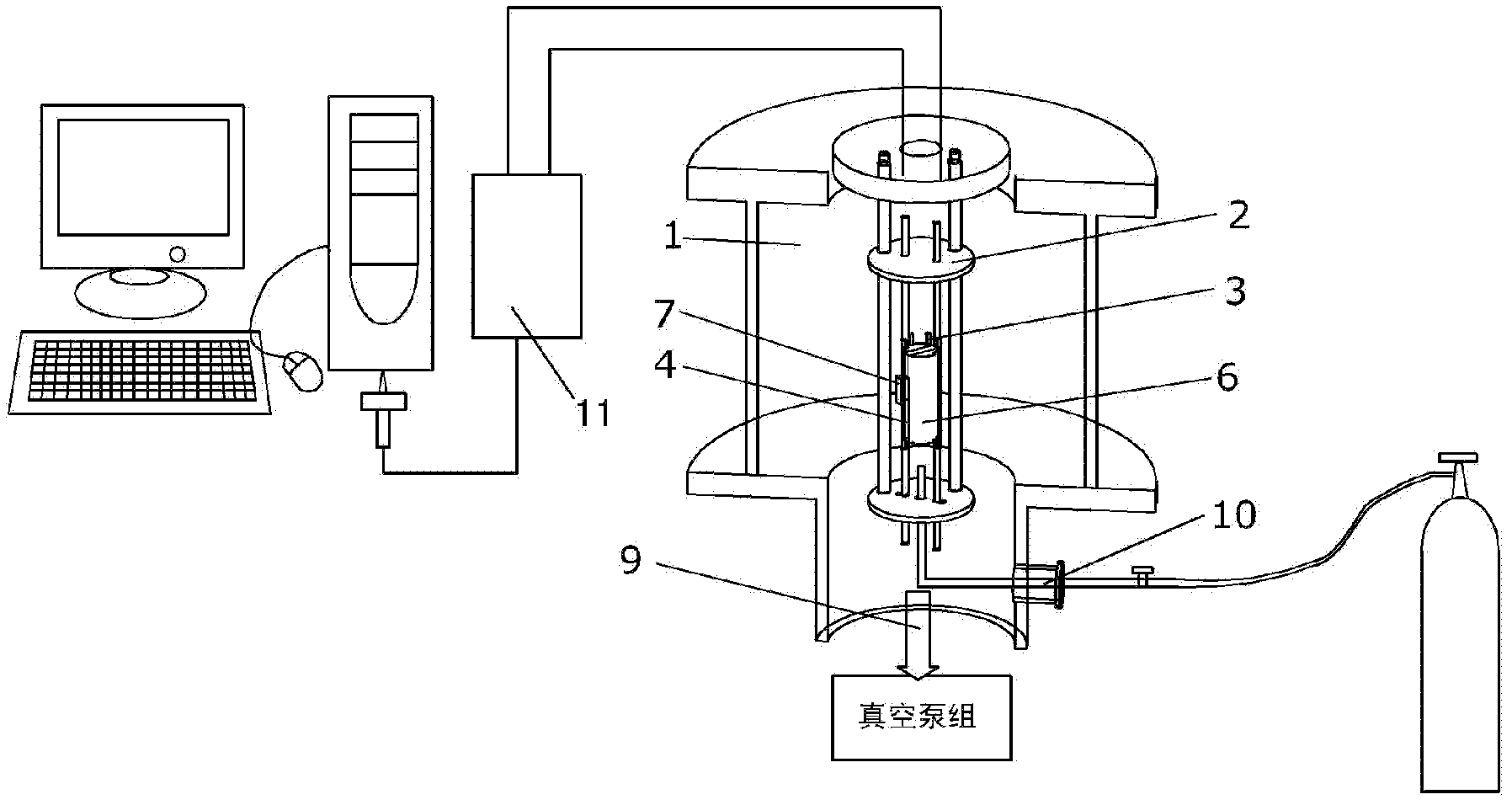

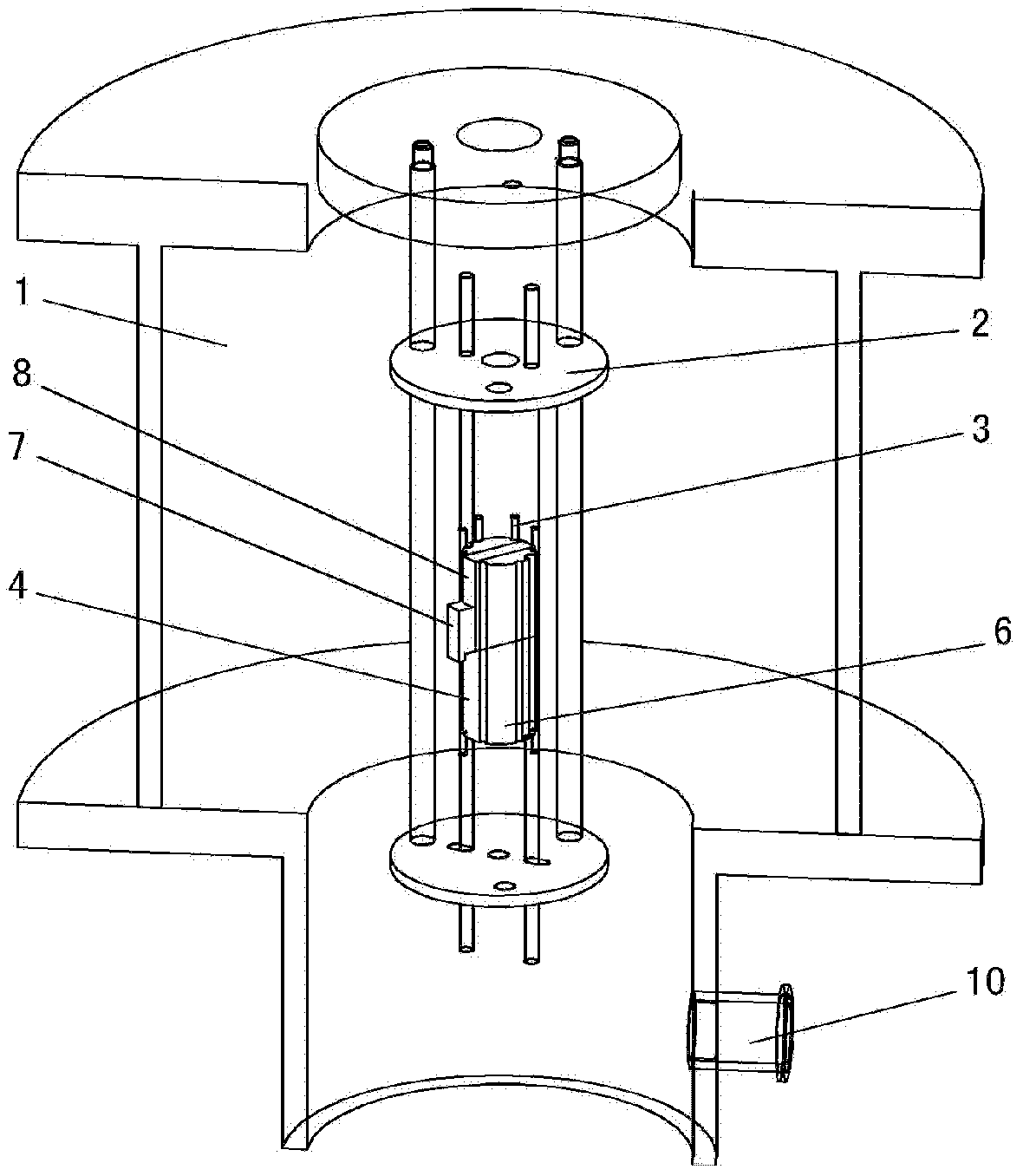

[0028] The structural form of the molten metal diffusion equipment in this embodiment is:

[0029] see figure 1 , figure 2 , a frame 2 is set in the vacuum chamber 1, and a diffusion table made of graphite is fixedly arranged in the frame 2; the diffusion table is a vertically fixed columnar body; a heating device 3 is arranged on the periphery of the diffusion table; The platform is a component, including:

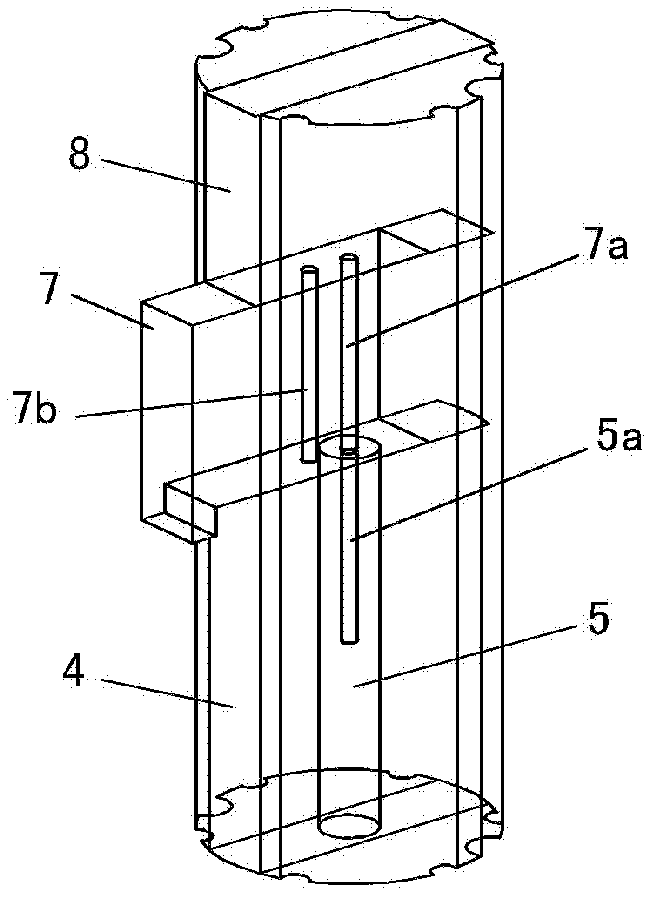

[0030] Such as figure 2 , Figure 3a and Figure 3b As shown, a fixed base 4 is set, and a fixed sample column 5 is arranged in the center of the fixed base 4 along the axial direction. The top surface of the base 4 is flush, and fixed splints 6 are respectively arranged on both sides of the diffusion table; the fixed base 4, the fixed sample column 5, the sliding block 7 and the fixed top plate 8 are clamped front and rear by the fixed splints 6; A slot for positioning the heating device 3 is provided on the top for heating, and a small hole leading to the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com