A Voltage Vector Closed-loop Compensation Method

A compensation method and voltage vector technology, applied in vector control systems, electrical components, control generators, etc., can solve problems such as current surge, voltage fluctuation, motor overexcitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

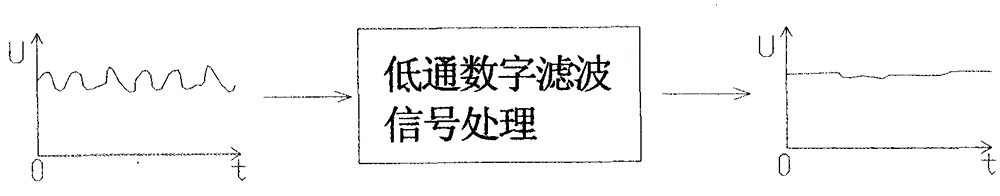

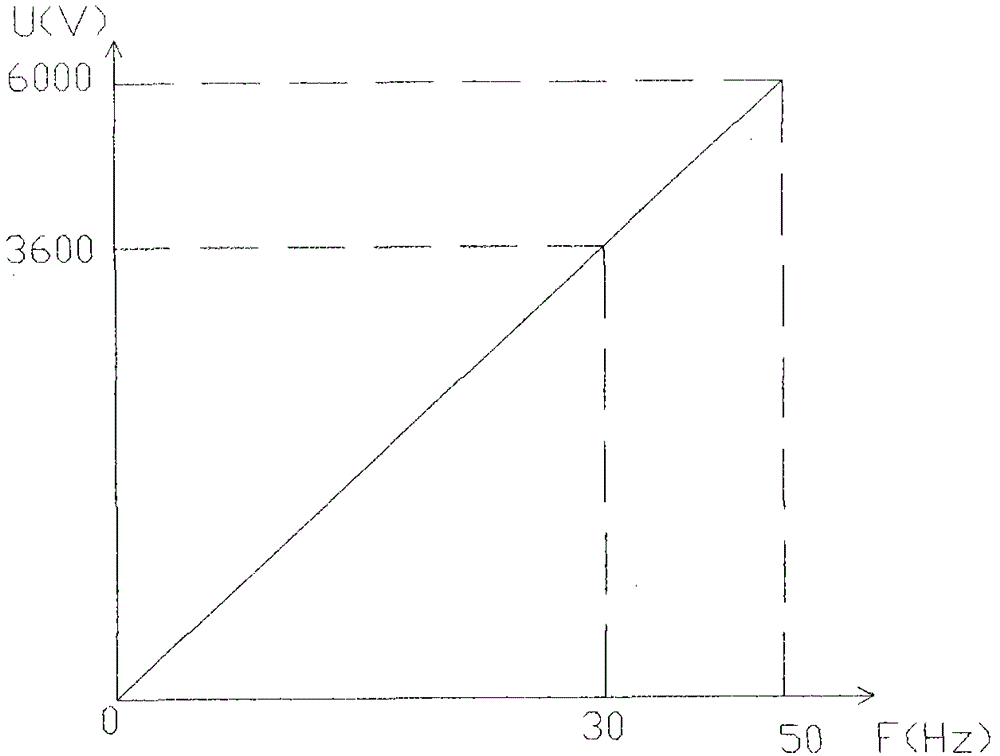

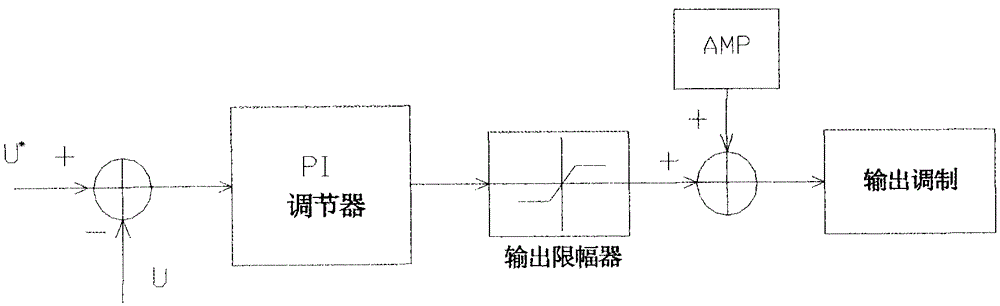

[0011] refer to Figure 1-Figure 3 , the specific implementation method adopts the following technical scheme: its compensation method is: start the frequency converter at a specified frequency f1, collect two line voltages of AB and BC, decompose the two line voltages into three phase voltages, and then according to 3 / 2 Transformation and vector value calculation formula to calculate the vector value U, calculate the standard value U* of the voltage that should be output at this time according to the rated operating frequency, rated voltage and current operating frequency of the load motor, compare the standard value U* with the feedback value U, and do PI adjustment, the output value is directly added to the original voltage output amplitude AMP, and finally modulated and output to the actuator.

[0012] This specific embodiment calculates the voltage vector at this time by detecting the amplitude of the output line voltage, and then compares it with the output voltage vecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com