Pressure filter device

A filter device and pressure technology, applied in the direction of filter circuit, filter separation, membrane filter, etc., can solve the problem of time-consuming decomposition, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

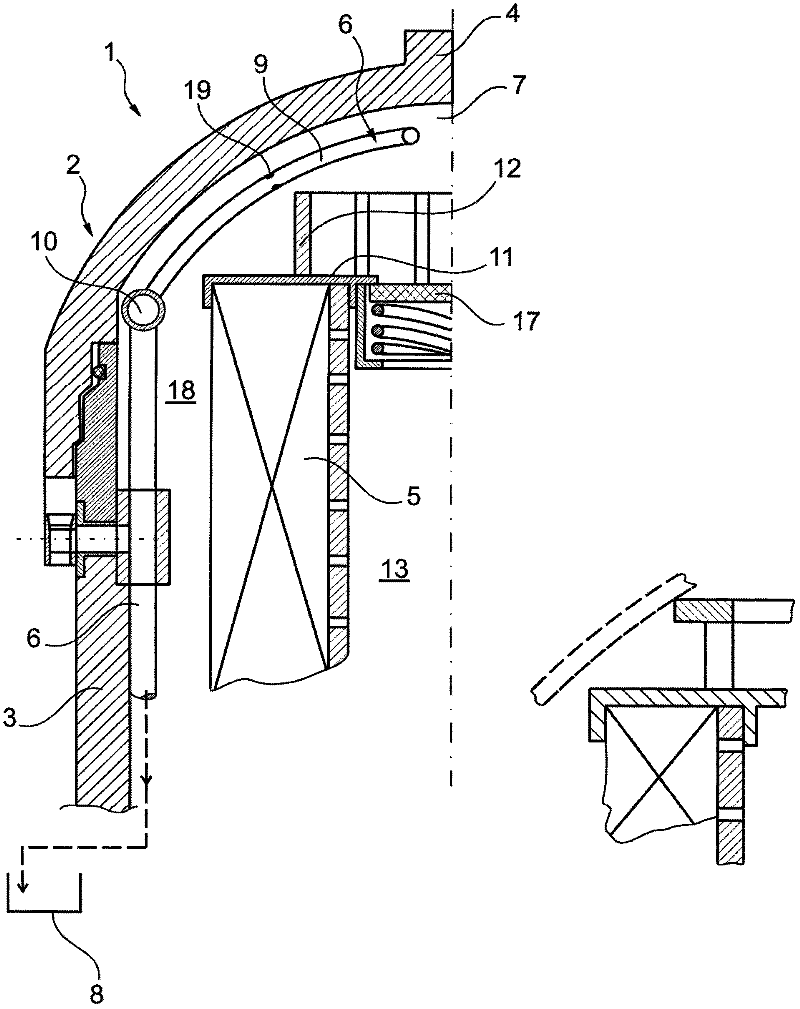

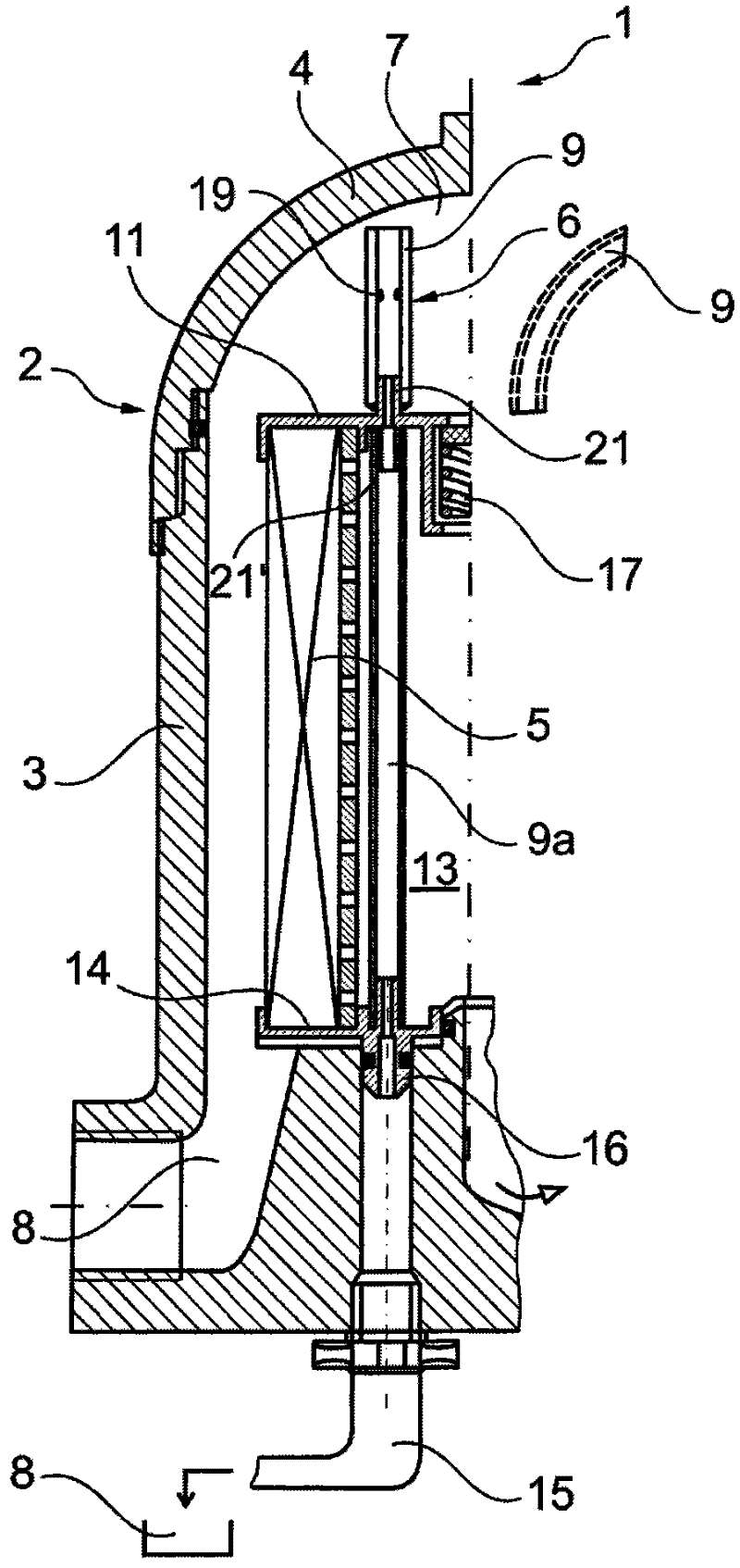

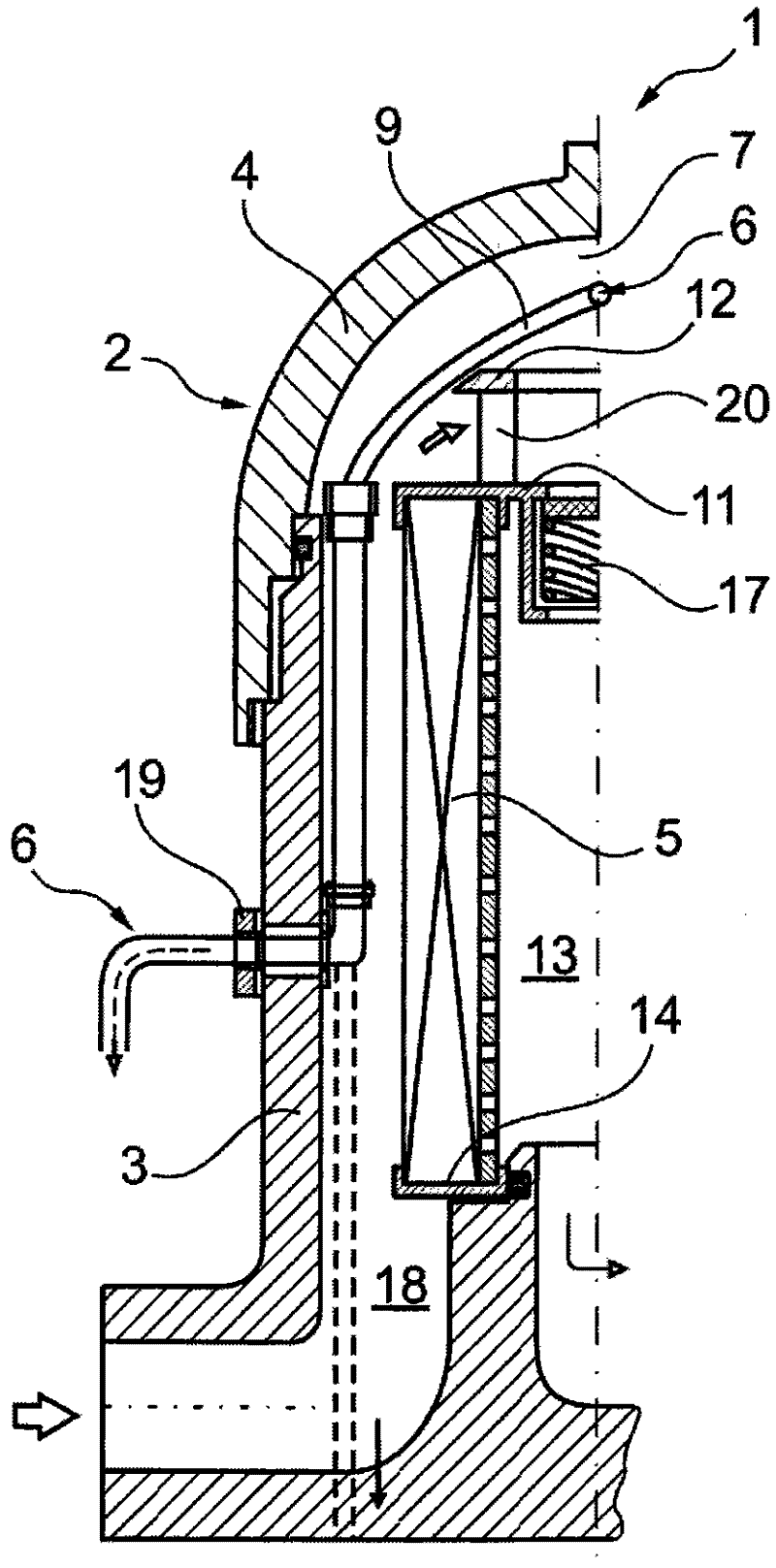

[0015] according to figure 1 , the pressure filter device 1 according to the invention is in particular configured as a hydraulic filter device and operates, for example, in a pressure range between approximately 16 and 20 bar, the pressure filter device 1 comprising a filter housing 2 which essentially consists of a filter housing tank 3 and a filter housing tank 3 and A rotatable filter housing cover 4 consists, in particular, of a rotatable filter housing cover 4 which can be connected to said filter housing pot 3 in a pressure-tight manner. in accordance with Figures 1 to 3 In the filter housing 2 , only the left half of which is shown in each case, a filter element 5 , in particular of the annular filter element type, is accommodated in the filter housing 2 . According to the present invention, in accordance with Figures 1 to 3 A ventilation line 6 is attached to the filter housing 3 of the pressure filter device 1 of the ® pressure filter device 1 , which connects th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com