High-redundancy beam-string truss structure and implementation method

A string truss, high-redundancy technology, applied in building components, building structures, roofs, etc., can solve the problems of lower chord flexible cables occupying large indoor headroom, upper chord truss collapse, adjacent structure damage, etc., to achieve safety Improved performance, delayed collapse, reduced sag height effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The high-redundancy string tension truss structure and implementation method provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

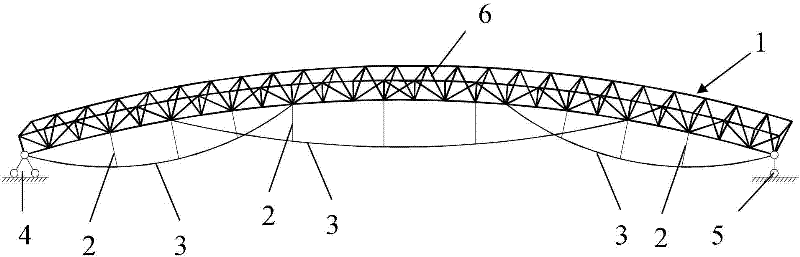

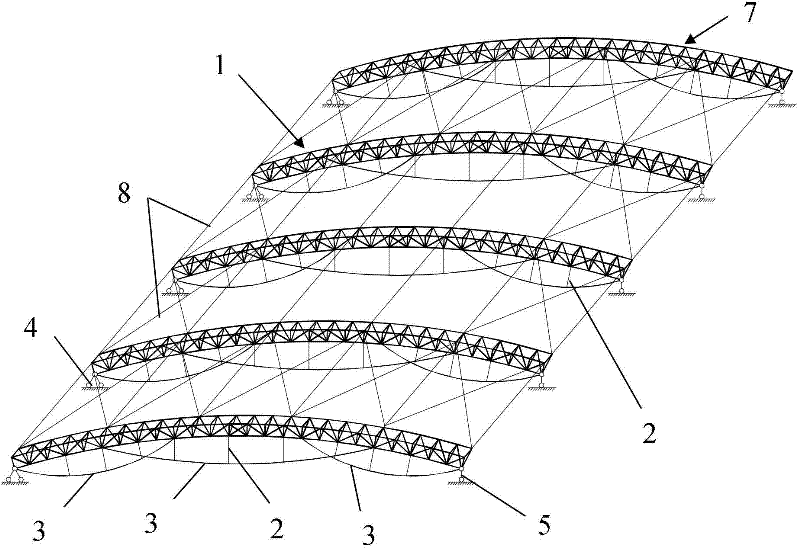

[0025] Such as figure 1 As shown, the high-redundancy chord truss structure provided by the present invention includes an upper chord truss 1, a plurality of struts 2, a plurality of stay cables 3, a fixed hinge support 4 and a sliding hinge support 5, wherein the upper chord truss 1 is composed of A plurality of upper chord truss members 6 are connected to each other by bolt balls or welded balls to form an upright triangular pyramidal space arch truss; the two ends of each stay cable 3 are connected to the two spherical nodes at the bottom of the upper chord truss 1 at a distance, and Partial structures of multiple stay cables 3 are arranged in a staggered manner; multiple struts 2 are vertically connected between the lower part of the upper chord truss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com