Underwater plugging and unplugging connector

A plug-in connector and plug-in terminal technology, which is applied in the field of underwater plug-in connectors, can solve problems such as poor insulation performance and fluidity, poor sealing effect, and low product qualification rate, so as to increase sealing reliability and reduce Compatibility requirements, effect of sealing dimension guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

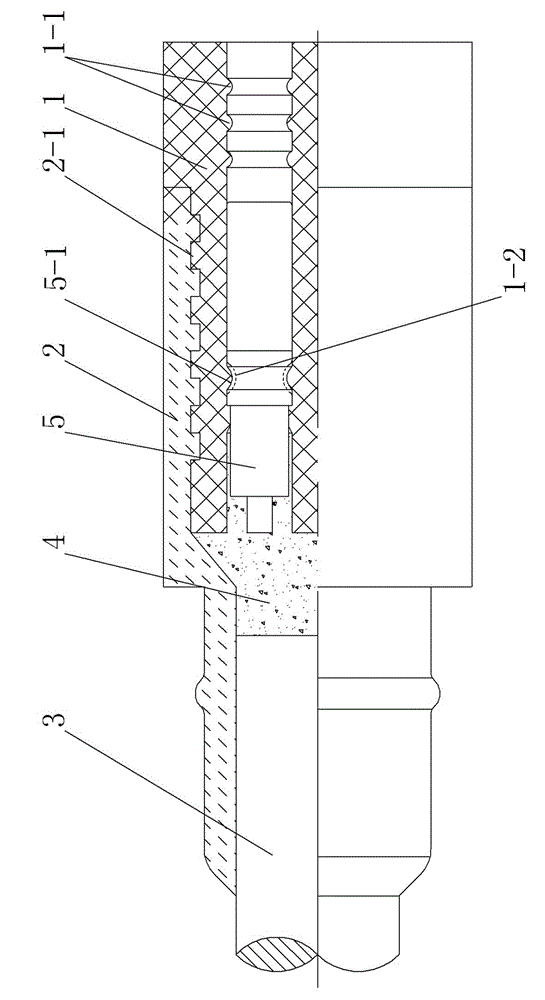

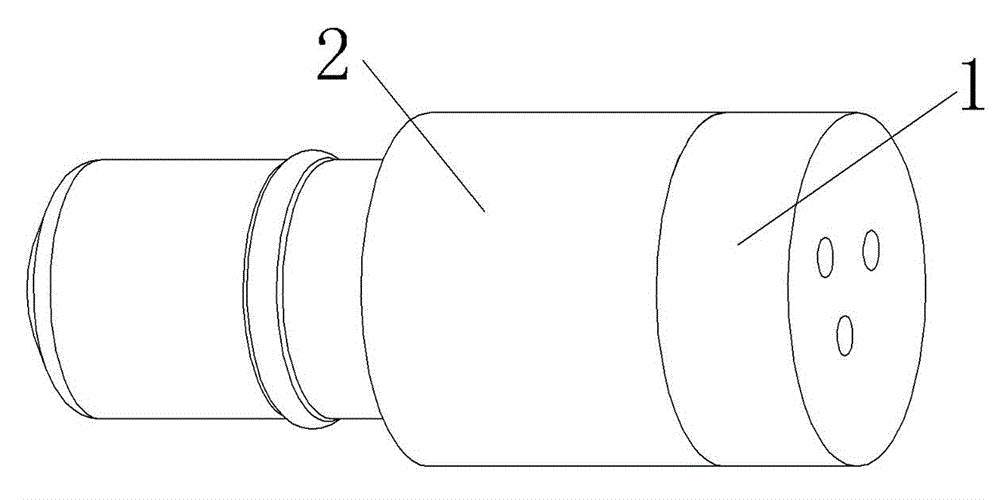

[0016] An embodiment of an underwater plug connector such as Figure 1~2 Shown: Including the insulator whose front end is a plug-in terminal, the insulator 1 is provided with a contact mounting hole that runs through its front and rear end faces, the contact 5 is installed at the rear end of the contact mounting hole, and the hole wall of the contact mounting hole is protruded. The rear flexible extrusion drain ring protrusion 1-2 is interference-squeezed with the outer peripheral surface of the contact member 5 to prevent the corresponding water flow from passing through. Press-fit inner concave ring groove 5-1. The front end wall of the contact installation hole is protruded with a front flexible squeeze drain ring protrusion 1-1 for interference extrusion fit with the outer periphery of the matching contact of the corresponding matching connector to prevent the corresponding water flow from passing through. The rear end of the contact piece 5 is connected with a cable 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com