Rivet welding device for vehicle frame accessories of mining dump truck and use method

A technology for mining dump trucks and frames, which is applied in the field of riveting and welding devices for mining dump truck frame accessories, which can solve the requirements of low riveting efficiency of frame accessories, low effective utilization of frame tooling, and the ability of workers to recognize pictures Advanced issues to achieve the effect of improving the effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

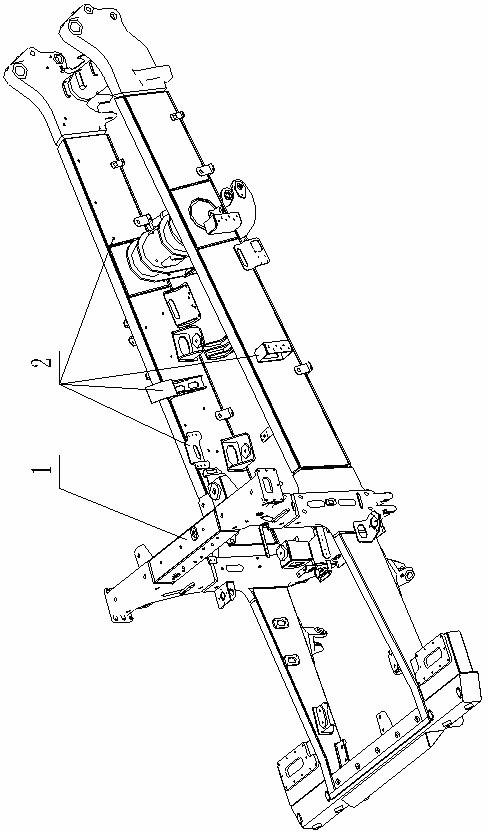

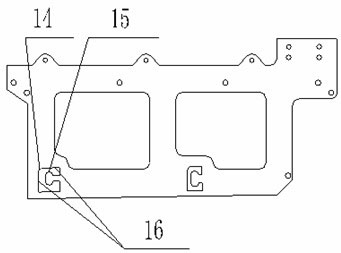

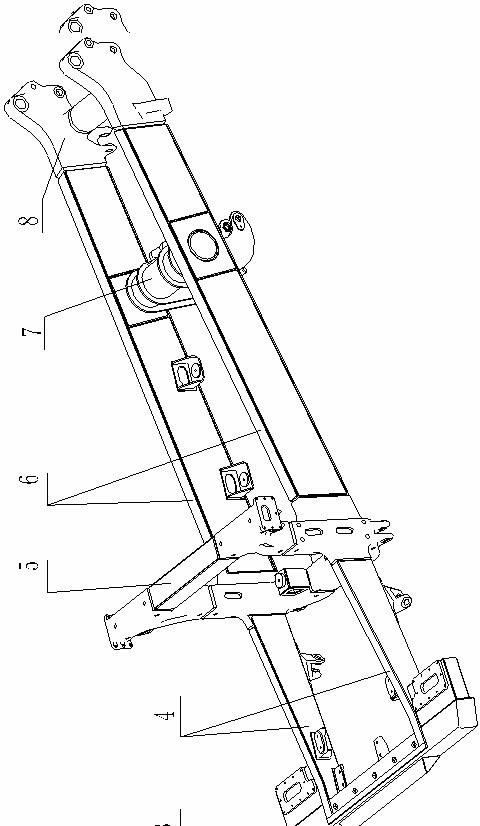

[0032] Such as image 3 and Figure 4 As shown, the embodiment of the present invention provides a mining dump truck frame attachment riveting device, the riveting device includes: a model 11, the model 11 is based on the shape of the part, the installation position of the frame attachment 2 given and The parts at the welding position; the positioning datum, which is the basic frame 1 (see figure 2 ) in the existing machining holes or the shape of some parts; the positioning element 12, which is a component that can determine the exact position of the template 11 from the positioning reference; the fixture 10, which can fix the template 11 Components on base frame 1. Wherein, there are multiple positioning elements 12 and clamps 10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap