Bearing unit for high rotational speeds

A support unit, high-speed technology, applied in the direction of continuous winding spinning machine, textile and papermaking, open-end spinning machine, etc. The effect of good stability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

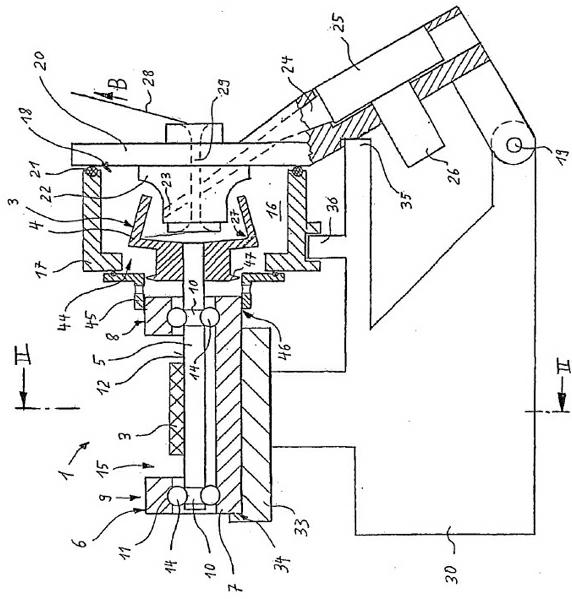

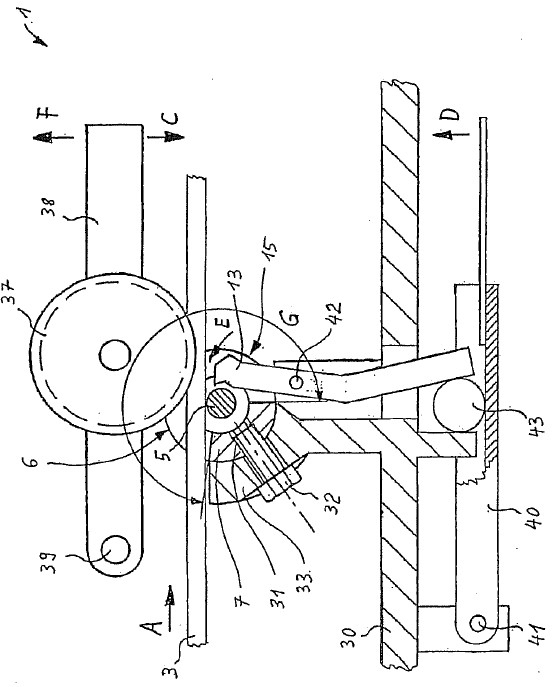

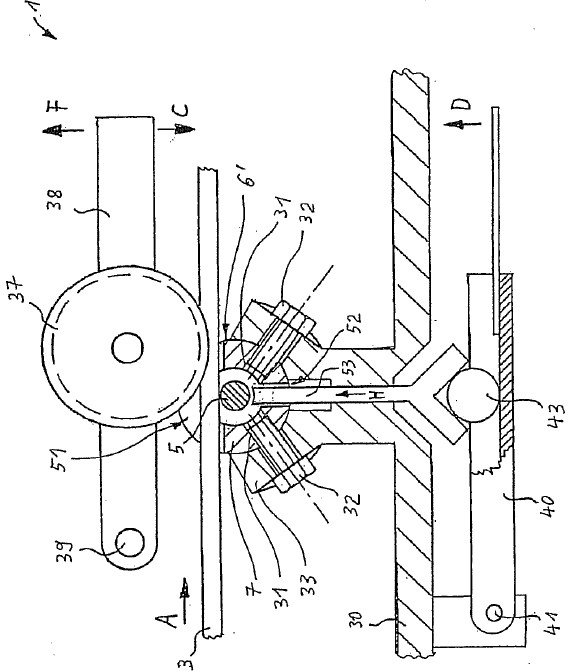

[0017] figure 1 and 2 The open-type textile machine 1 shown in contains a textile machine rotor 2 and a tangential drive belt 3 running in the running direction. The textile machine rotor 2 contains a rotor disk 4 which is mounted on a shaft 5 of a bearing unit 6 . The bearing unit 6 contains a bearing housing 7 in which two rolling bearings 8 and 9 are located. The shaft 5 and the bearing housing 7 each have raceways 10 , 11 for rolling bodies 14 . The bearing housing 7 is designed in the form of a sleeve and directly forms the outer ring for the rolling bearings 8 , 9 via the raceways 11 . The shaft 5 has a surface 12 which forms a running surface for driving the shaft via the tangential drive belt 3 . At the same time, the surface 12 forms a braking surface for braking the shaft by means of the brake pad 13 .

[0018] According to the invention it is provided that the running and braking surfaces 12 are arranged between the two raceways 10 of the rolling bodies 14 . F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com