Open multi-strand wire rope

A technology of steel wire rope and steel wire, applied in the field of multi-strand steel wire rope, can solve the problems of breaking load loss, tensile strength loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

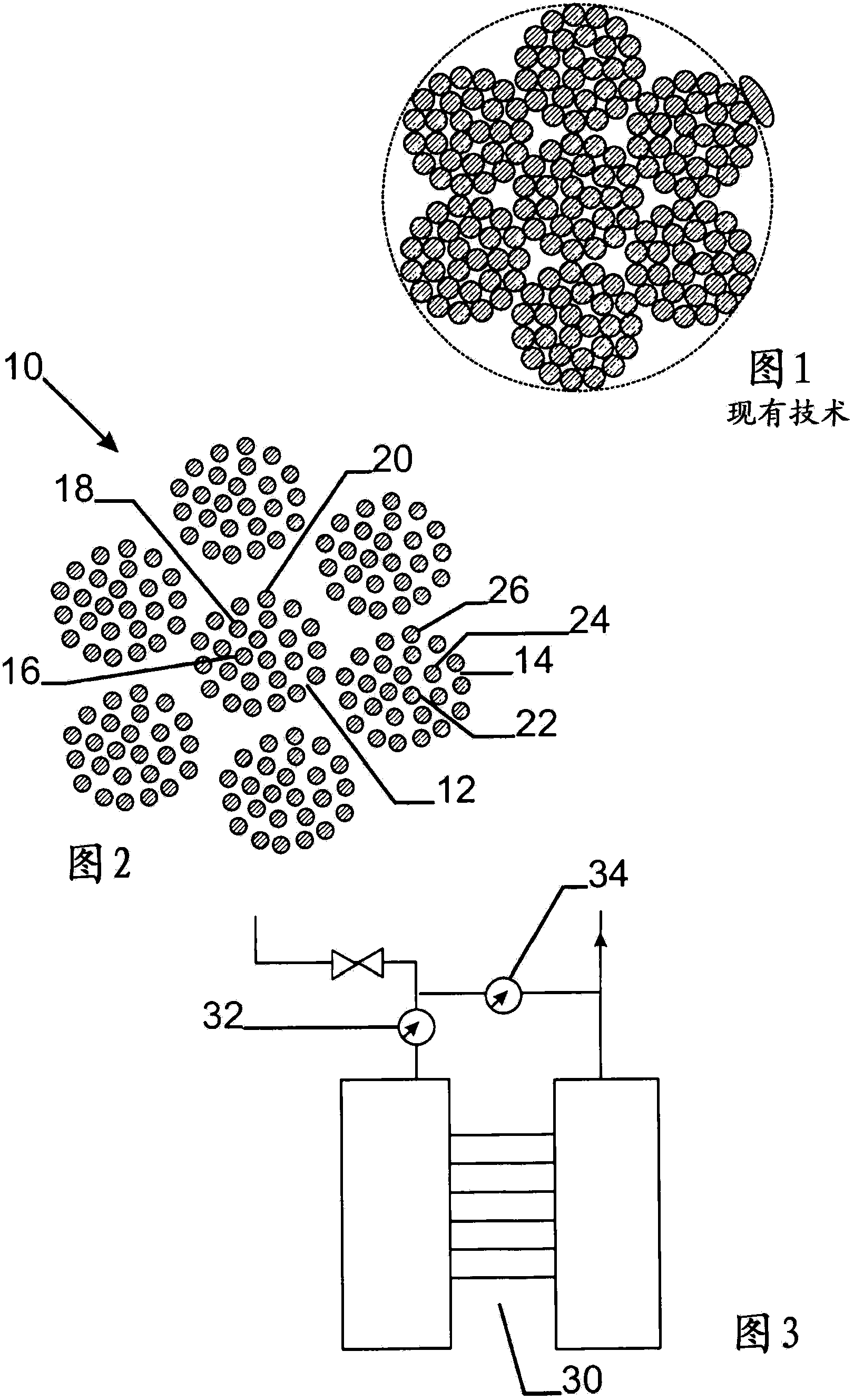

[0044] Embodiment 1: the following is the first embodiment according to the present invention

[0045] Wire rope diameter D is 4.50mm

[0046] The diameter D1 of the core strand 12 is 1.615mm

[0047] (Z-twist) 3×0.265mm (center steel wire 16), twist length is 6.3mm

[0048] (Z-direction twist) +8×0.265mm (steel wire 18), the twist length is 12.5mm

[0049] (Z-direction twist) +14×0.265mm (steel wire 20), the twist length is 18mm;

[0050] alpha 2 =11.87°; α 3 =13.41°

[0051] The diameter D2 of the six peripheral strands 14 is 1.493mm;

[0052] (Z-twist) 3×0.245mm (center wire 22), twist length is 6.3mm

[0053] (Z-direction twist) +8×0.245mm (steel wire 24), the twist length is 12.5mm

[0054] (Z-direction twist) +14×0.245mm (steel wire 26), lay distance is 18mm;

[0055] alpha 2 =10.99°; α 3 =12.43°

[0056] Rope: lay length is 50mm, lay in S direction.

[0057] The ratio of D1 / D2 is 1.082. The weight of the wire rope per meter is 68.3 grams, and the breaking ...

Embodiment 2

[0080] Wire rope diameter D is 4.50mm

[0081] Core strand diameter D1 is 1.574mm

[0082] (Z-twist) 2×0.285mm (central steel wire), lay distance is 6.3mm

[0083] (Z-direction twist) +8×0.265mm (steel wire), lay length is 12.5mm

[0084] (Z-direction twist) +14×0.265mm (steel wire), the twist length is 18mm;

[0085] alpha 2 =11.85°; α 3 =13.40°

[0086] The diameter D2 of the six peripheral strands is 1.455mm;

[0087] (Z-twist) 2×0.265mm (central steel wire), lay distance is 6.3mm

[0088] (Z-twist) +8×0.245mm (steel wire), the twist length is 12.5mm

[0089] (Z-direction twist) +14×0.245mm (steel wire), the twist length is 18mm;

[0090] alpha 2 =11.02°; α 3 =12.45°

[0091] Rope: lay length is 50mm, lay in S direction.

Embodiment 3

[0093] The diameter D of the wire rope is 4.50mm

[0094] The diameter D1 of the core strand is 1.615mm

[0095] (Z-twist) 3×0.265mm (central steel wire), lay length is 6.3mm

[0096] (Z-direction twist) +8×0.265mm (steel wire), lay length is 12.5mm

[0097] (Z-direction twist) +14×0.265mm (steel wire), the twist length is 18mm;

[0098] alpha 2 =11.87°;α 3 =13.41°

[0099] The diameter D2 of the six peripheral strands is 1.455 mm;

[0100] (Z-twist) 2×0.265mm (central steel wire), lay distance is 6.3mm

[0101] (Z-twist) +8×0.245mm (steel wire), the twist length is 12.5mm

[0102] (Z-direction twist) +14×0.245mm (steel wire), the twist length is 18mm;

[0103] alpha 2 =11.02°; α 3 =12.45°

[0104] Rope: lay length is 50mm, lay in S direction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com