Device and method for controlling a belt-type continuously variable transmission for a vehicle

A continuously variable transmission, control device technology, applied in the direction of elements with teeth, transmission control, belt/chain/gear, etc., can solve problems such as inability to ensure control accuracy, extraction, estimation error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0039] First, the configuration will be described.

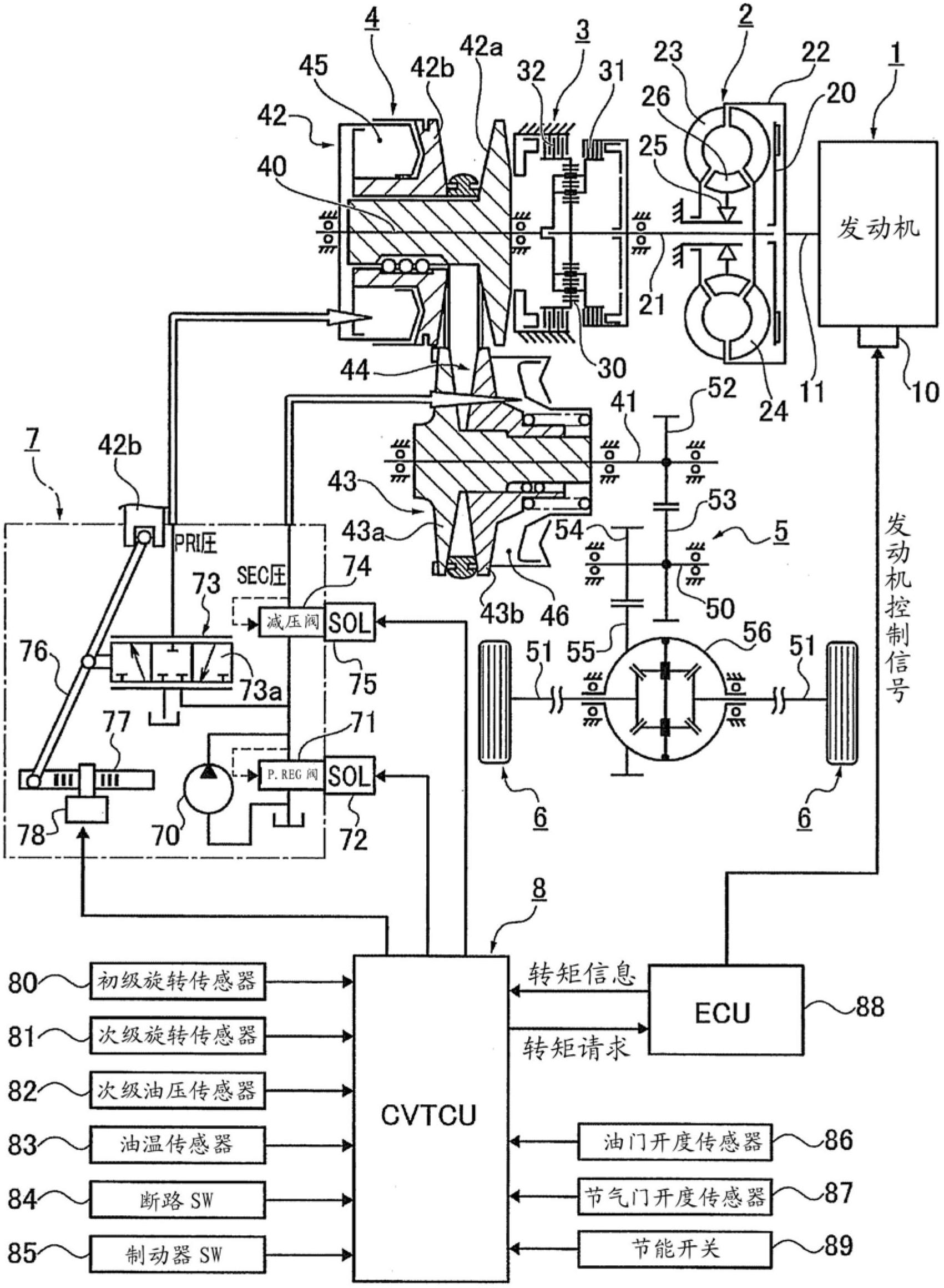

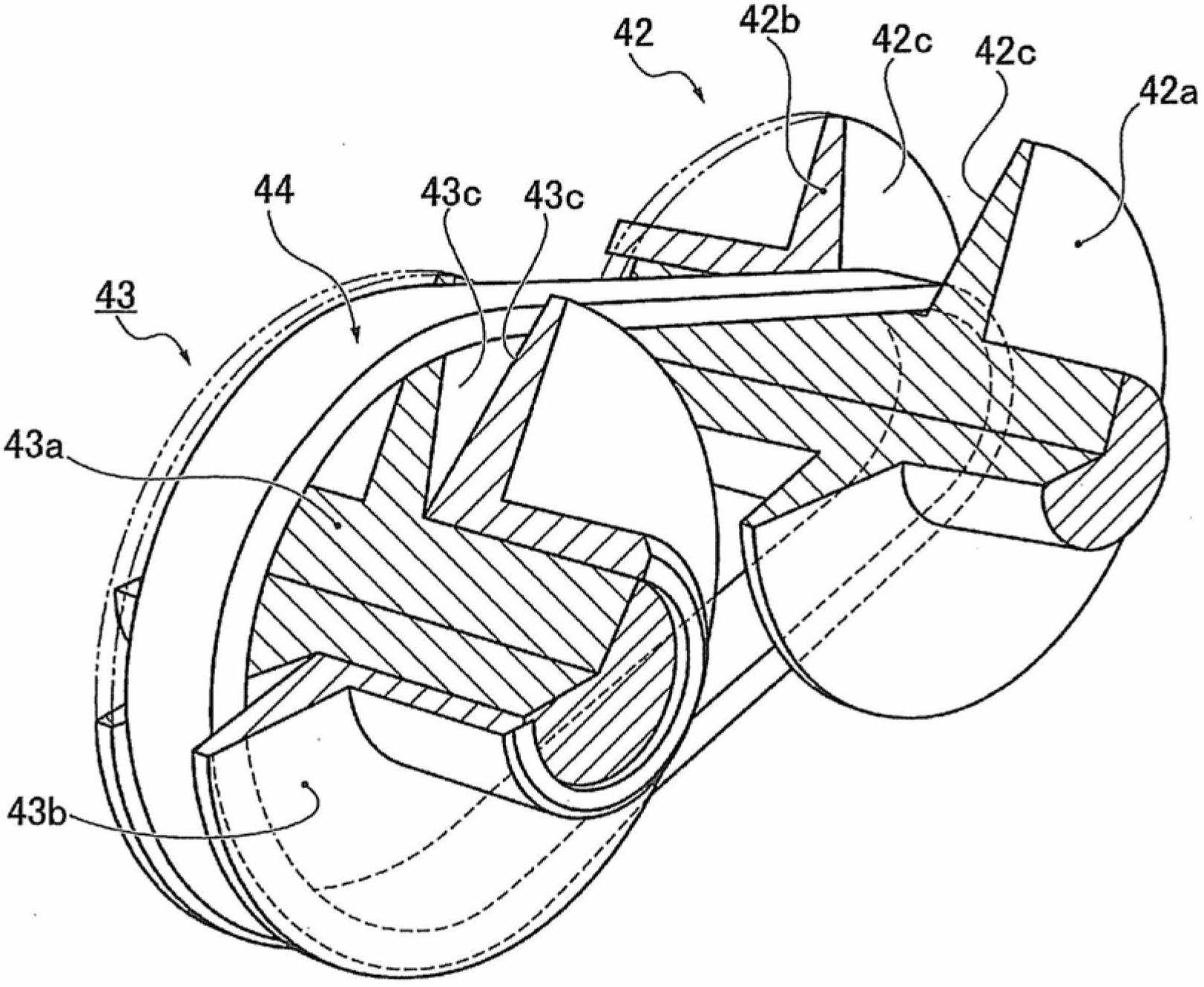

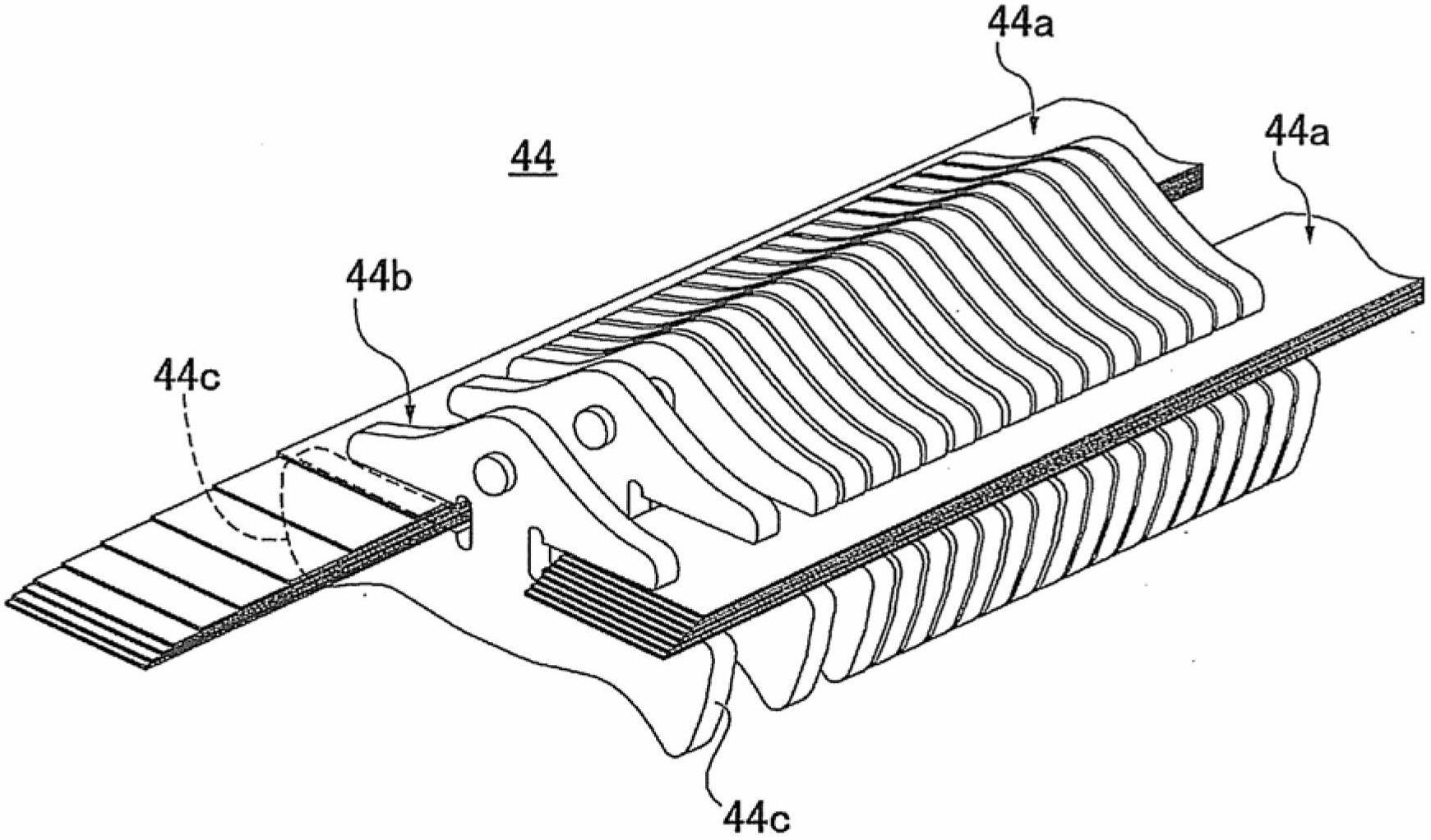

[0040] figure 1 It is an overall system diagram showing a drive system and a control system of a belt-type continuously variable transmission for a vehicle to which the control device and control method of the first embodiment are applied. figure 2 It is a perspective view showing a belt-type continuously variable transmission mechanism to which the control device and control method of the first embodiment are applied. image 3 It is a perspective view of a part of the belt of the belt-type continuously variable transmission mechanism to which the control device and control method of the first embodiment are applied. Below, based on Figure 1 ~ Figure 3 The system configuration will be described.

[0041] Such as figure 1 As shown, the drive system of the belt-type continuously variable transmission for vehicles includes an engine 1, a torque converter 2, a forward-reverse switching mechanism 3, a belt-type continuously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com