Branch wire system

A wiring and branching technology, applied in the directions of contacts, electromagnetic relay details, relays, etc., can solve the problems of increased installation area, wiring errors, increased installation area and cost of switchboards, etc., to reduce the number of parts and wiring man-hours , The effect of preventing wiring errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

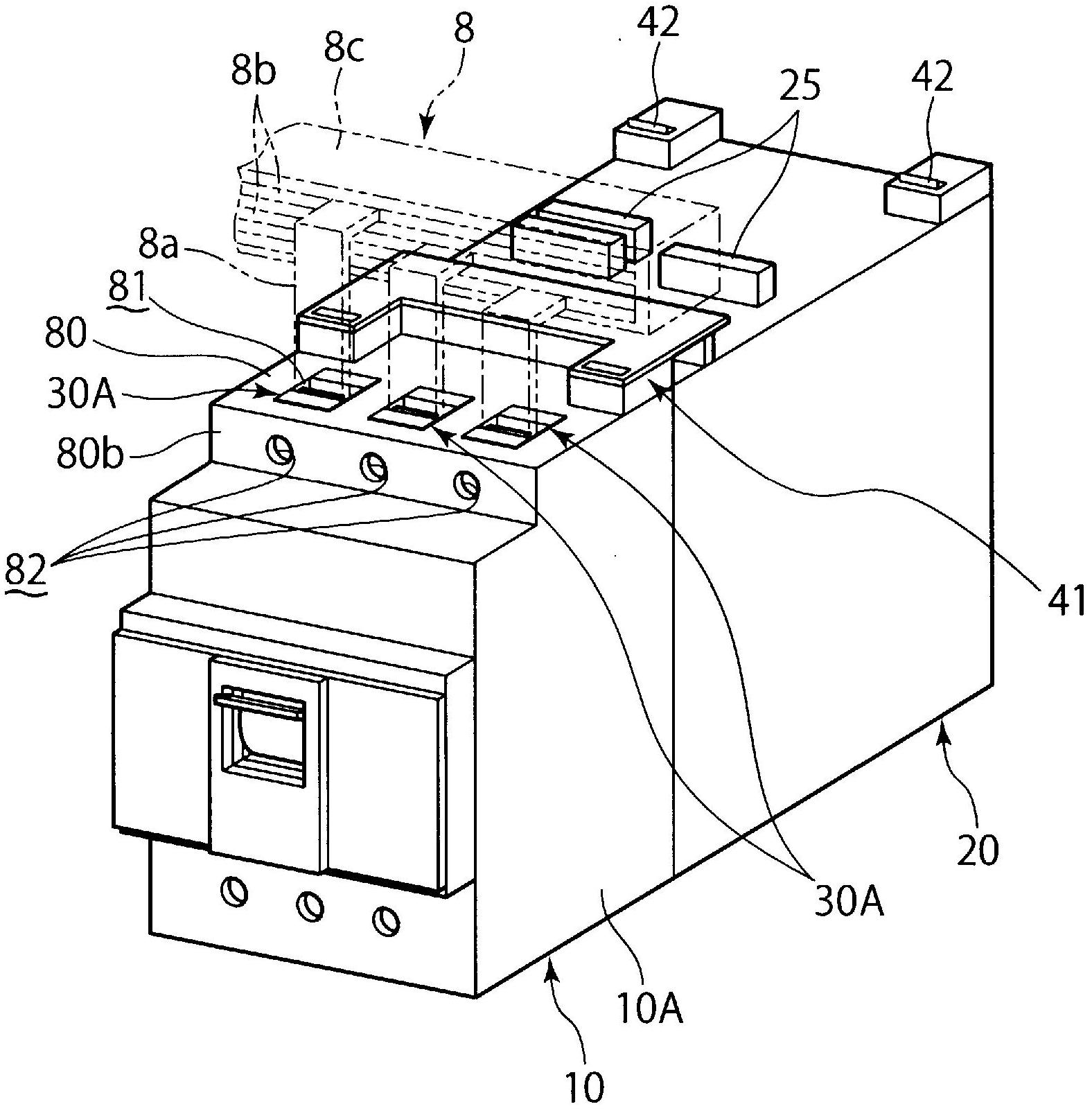

[0028] Embodiments of the present invention will be described below with reference to the drawings.

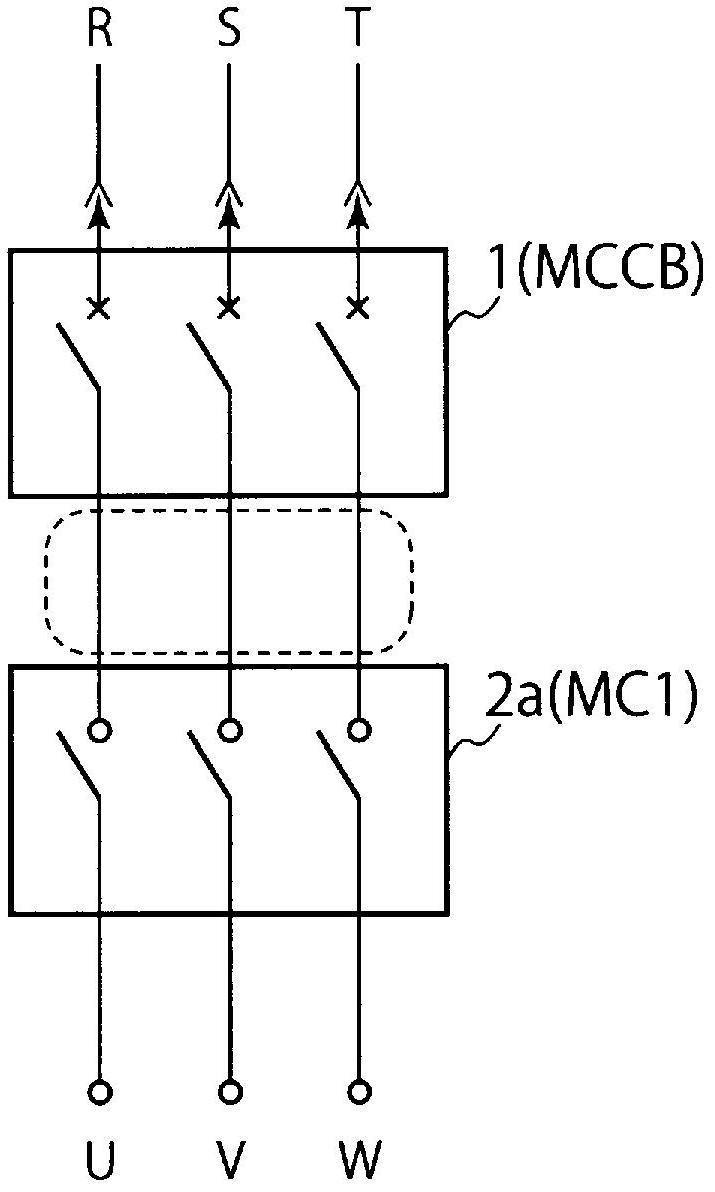

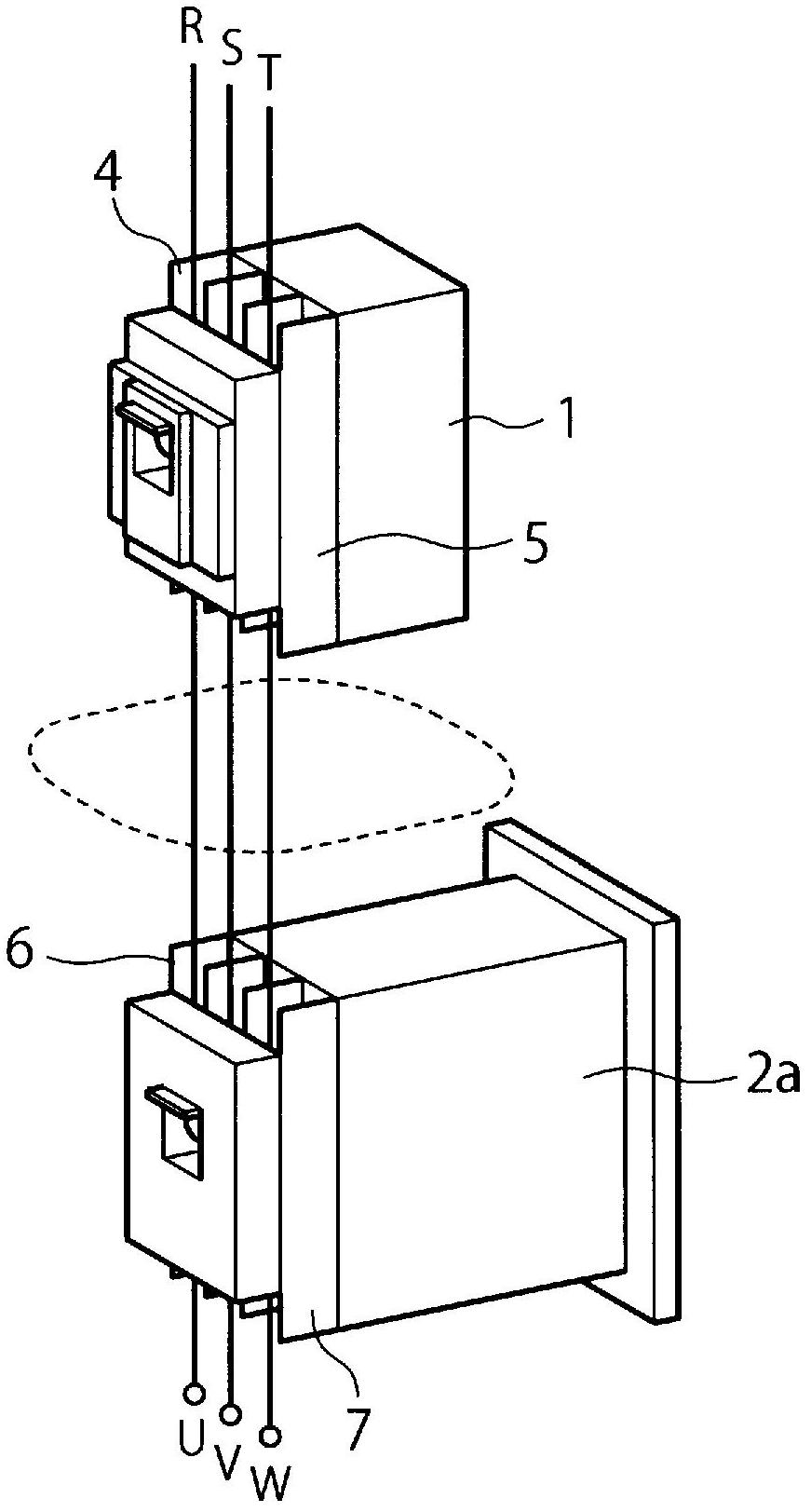

[0029] figure 1 and figure 2 Shows a distribution circuit breaker 1 (hereinafter referred to as "distribution circuit breaker") for branch lines subordinate to a main distribution circuit breaker (not shown) that is fixed in an unshown switchboard in a conventional structure. 1”) and part of the electromagnetic interrupter 2a. The three-phase R, S, T that supplies power to the primary side terminal part 4 of the distribution circuit breaker 1 (MCCB) is connected to the electromagnetic interrupter 2a (MC1) via the secondary side terminal part 5 of the distribution circuit breaker 1 The wires (the part surrounded by the dotted line) of the primary side terminal part 6 separated by phase (R (red), S (white), T (black)) are supplied to the electromagnetic interrupter 2a, and then supplied to the electromagnetic interrupter 2a. To the electrical loads (U, V, W) connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com