Multi-functional multi-specification combined tool set

A combined tool and multi-specification technology, applied in the field of hardware tools, can solve the problems of single angle of lighting, inconvenience, and large size of the lighting lamp, and achieve the effect of compact structure and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

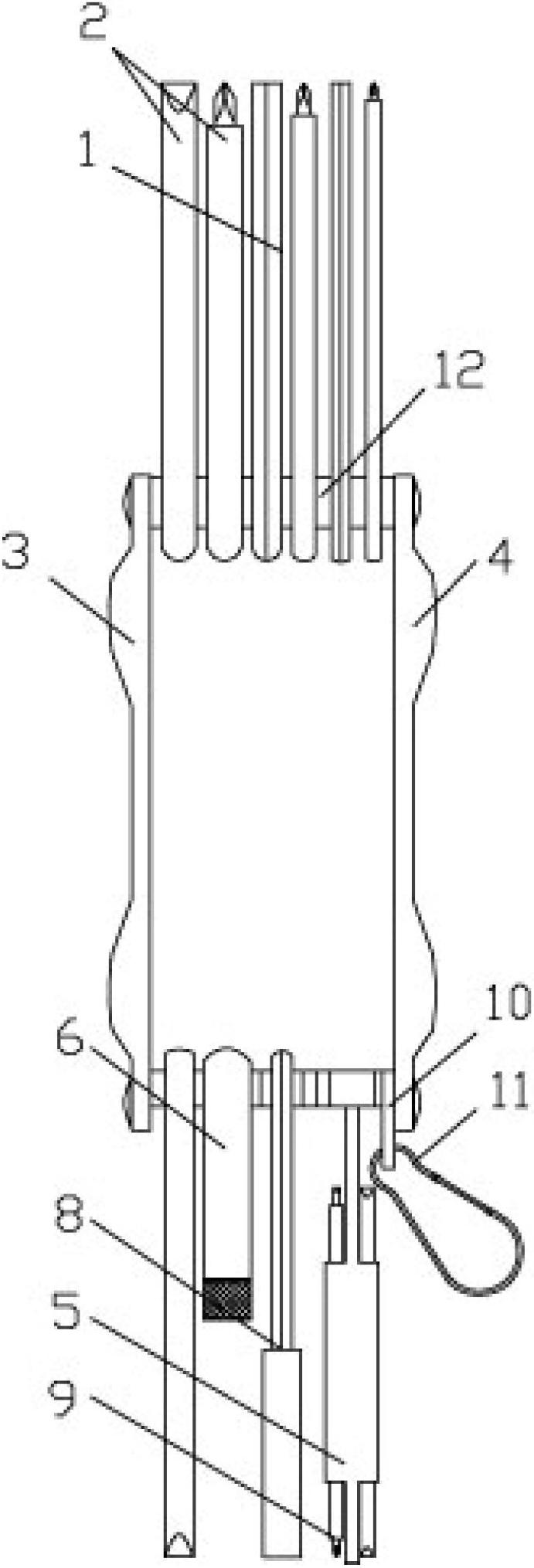

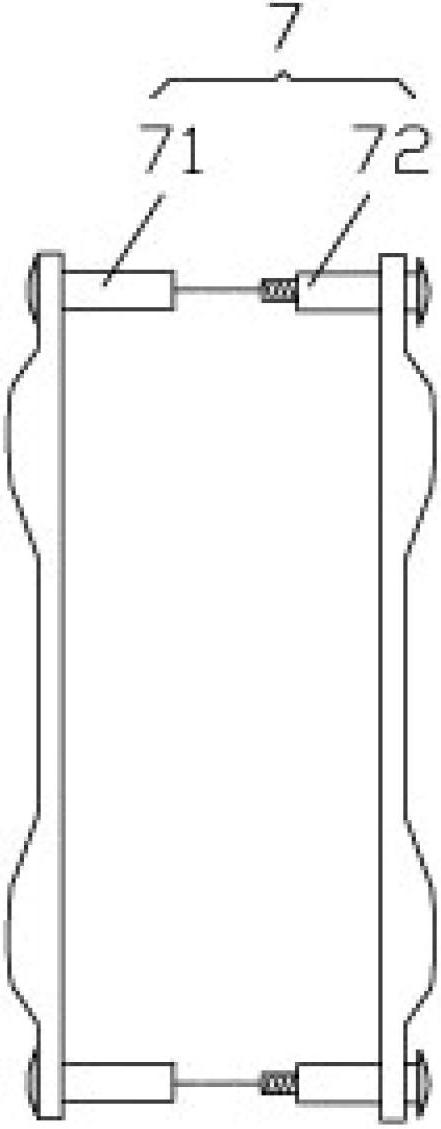

[0028] Example: see Figures 1 to 11 , a multi-functional and multi-standard set combination tool, including several different specifications of screwdrivers 2 or hexagonal rod cone 1, left combined plate frame 3, right combined plate frame 4 and docking shaft 7, the docking shaft 7 is made of belt The left butt joint shaft 71 and the right butt joint shaft 72 of the top of the hat are screwed together to form, and two left butt joint shafts 71 and two right butt joint shafts 72 are inserted and sleeved respectively on the left combined pallet 3 and the right combined pallet 4. in the hole;

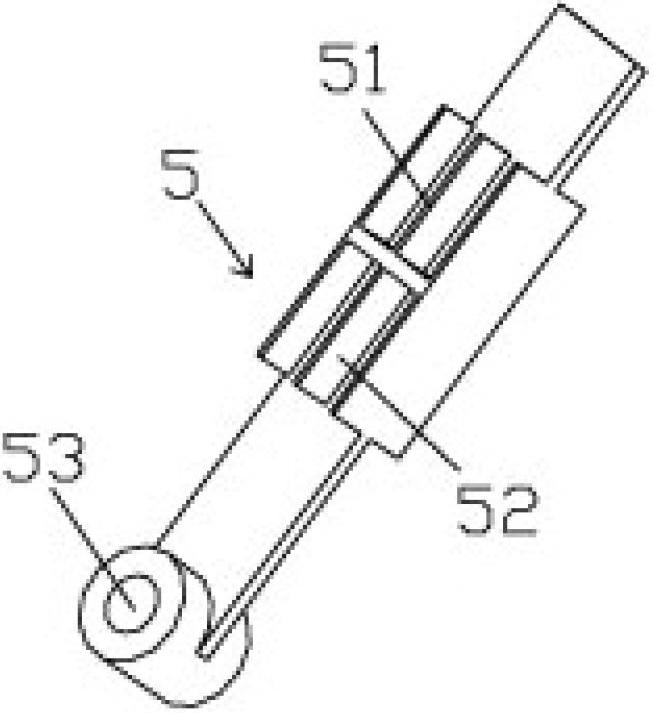

[0029] Screwdriver 2 or hexagonal rod cone 1, combined sleeve 8 and combined tool receiving seat 5 are hinged on the docking shaft 7, and several elastic partitions 51 are formed on the combined tool receiving seat 5, and each two elastic partitions 51 Form a receiving card slot 52 between them, and the combination tool head 9 is elastically clamped in the receiving card slot 52. The com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com