Fastening structure and seal box with the fastening structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The present invention will now be described in more detail hereinafter with reference to the accompanying drawings as follows:

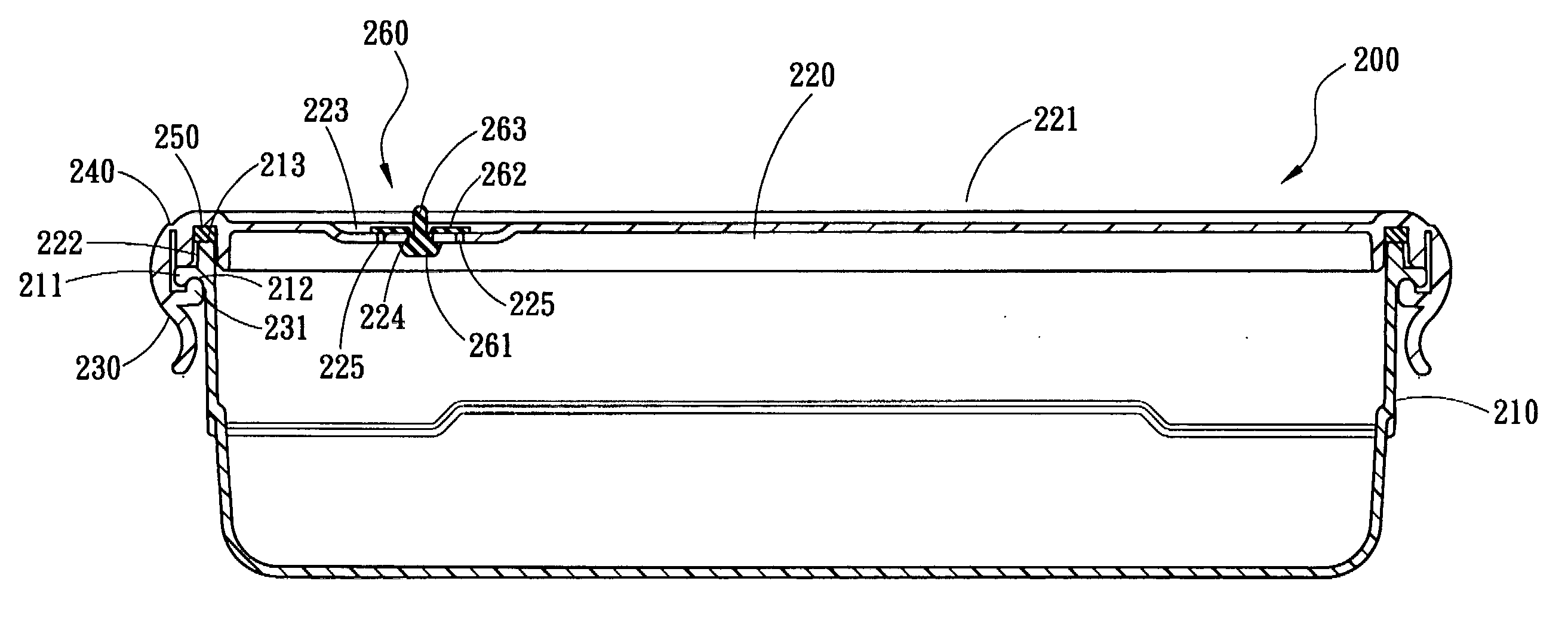

[0026]Referring to FIG. 4A to 6, a plastic sealed box 200 in accordance with a preferred embodiment of the present invention. The sealed box 200 is made of a plastic material and comprises a container 210 and a cover 220. The container 210 has a latch structure 211 protruded from a position proximate to the periphery of the top edge 213 of the container 210 and a latch portion 212 under the latch structure 211. The periphery of the cover 220 has a plurality of fastening flanges 230 (each is a rectangular sealed box 200 with four sides), and each fastening flange 230 is connected to the periphery of the cover 220 through a hinge portion 240 for bending and turning the fastening flange 230 with respect to the periphery of the cover 220 through the hinge portion 240. The hinge portion 240 forms a plurality of sections of crevices 242, such as 0.2 mm crevic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Stress optical coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com