Vibration sieve for reducing omitted mounting of inserts of products

A technology of vibrating screen and insert, applied in vibrating conveyor, transportation and packaging, conveyor, etc., can solve the problems of increasing working hours, quality impact, product rework, etc., to save working hours, timely and accurate quantity, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

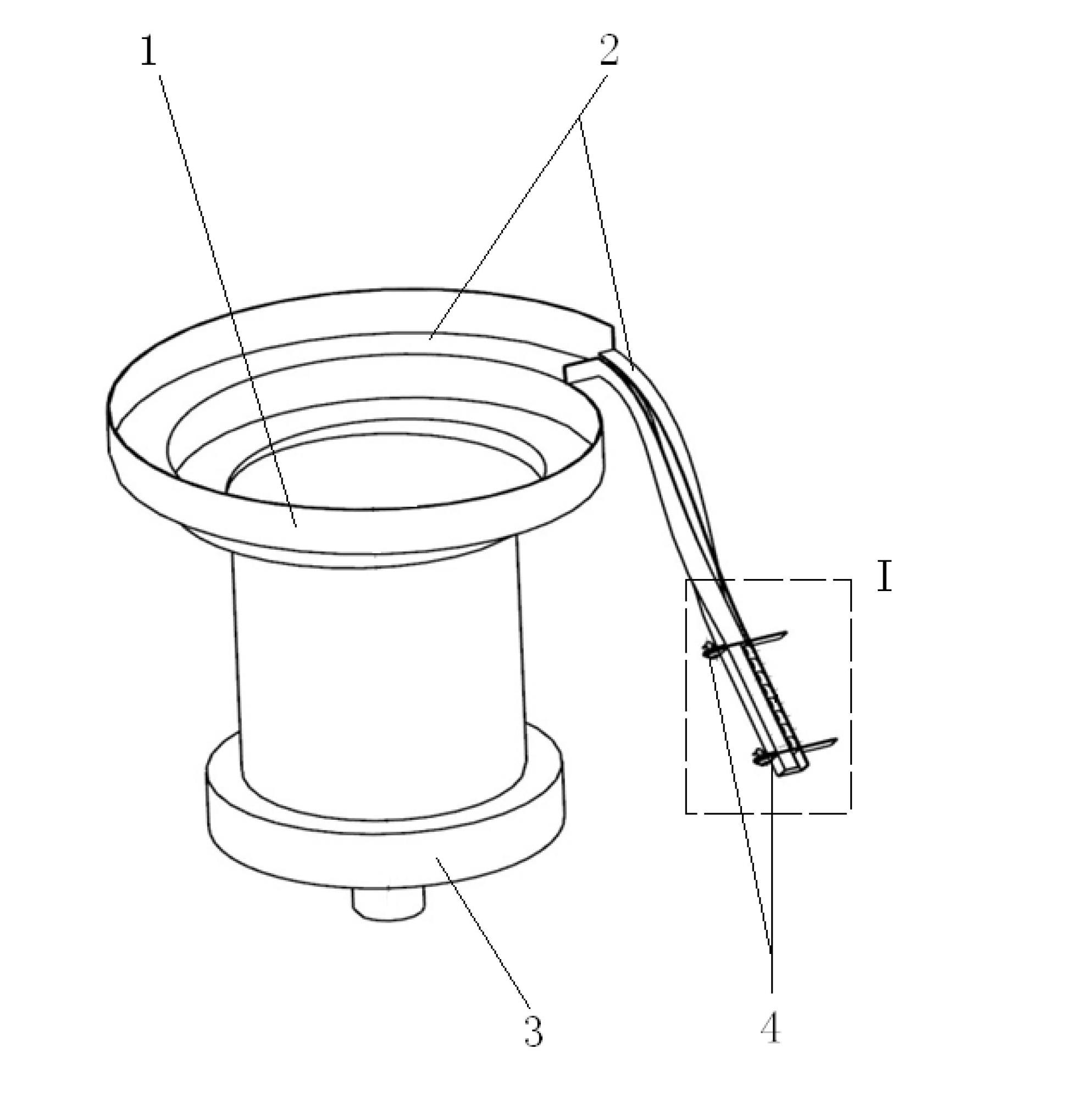

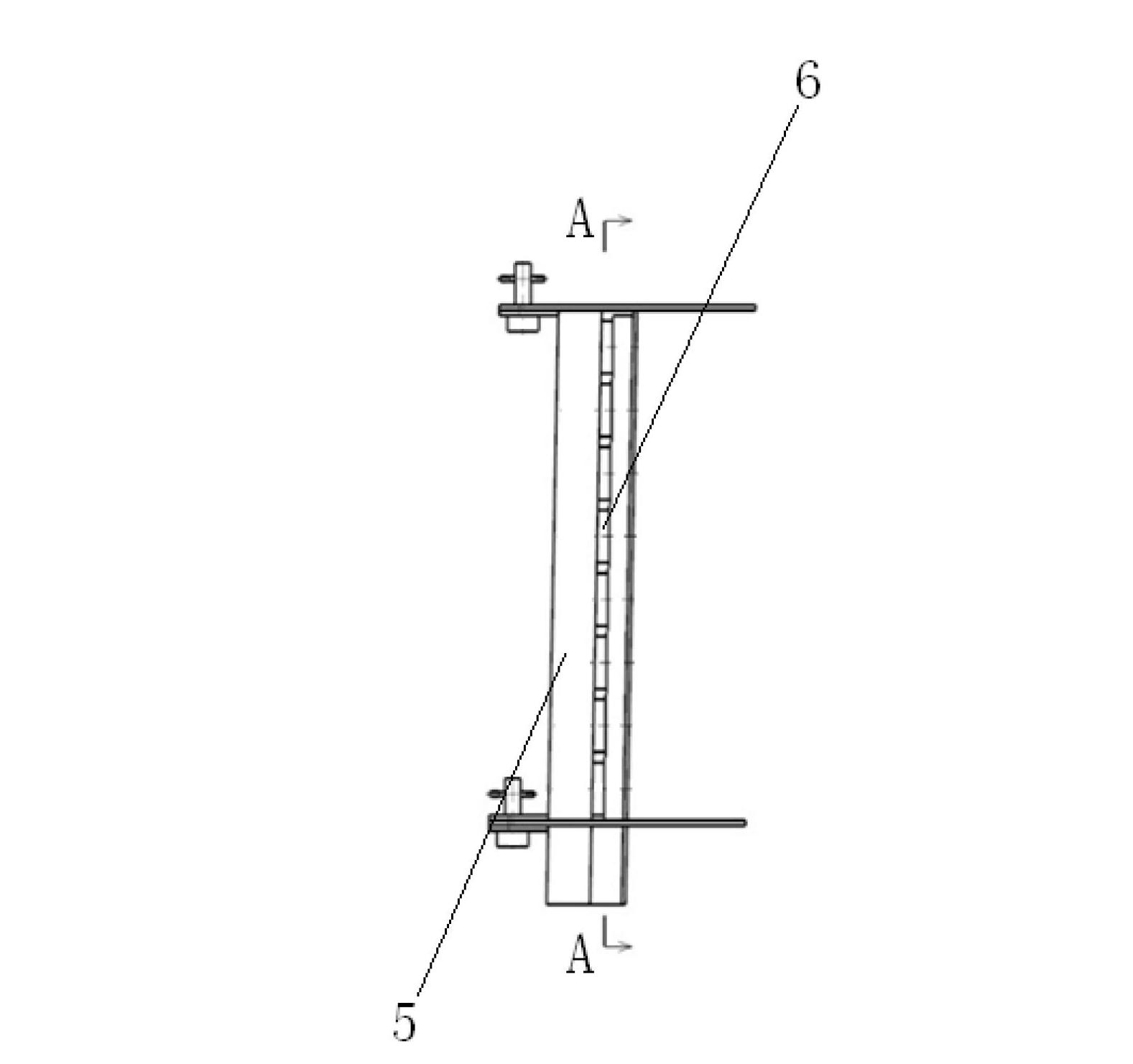

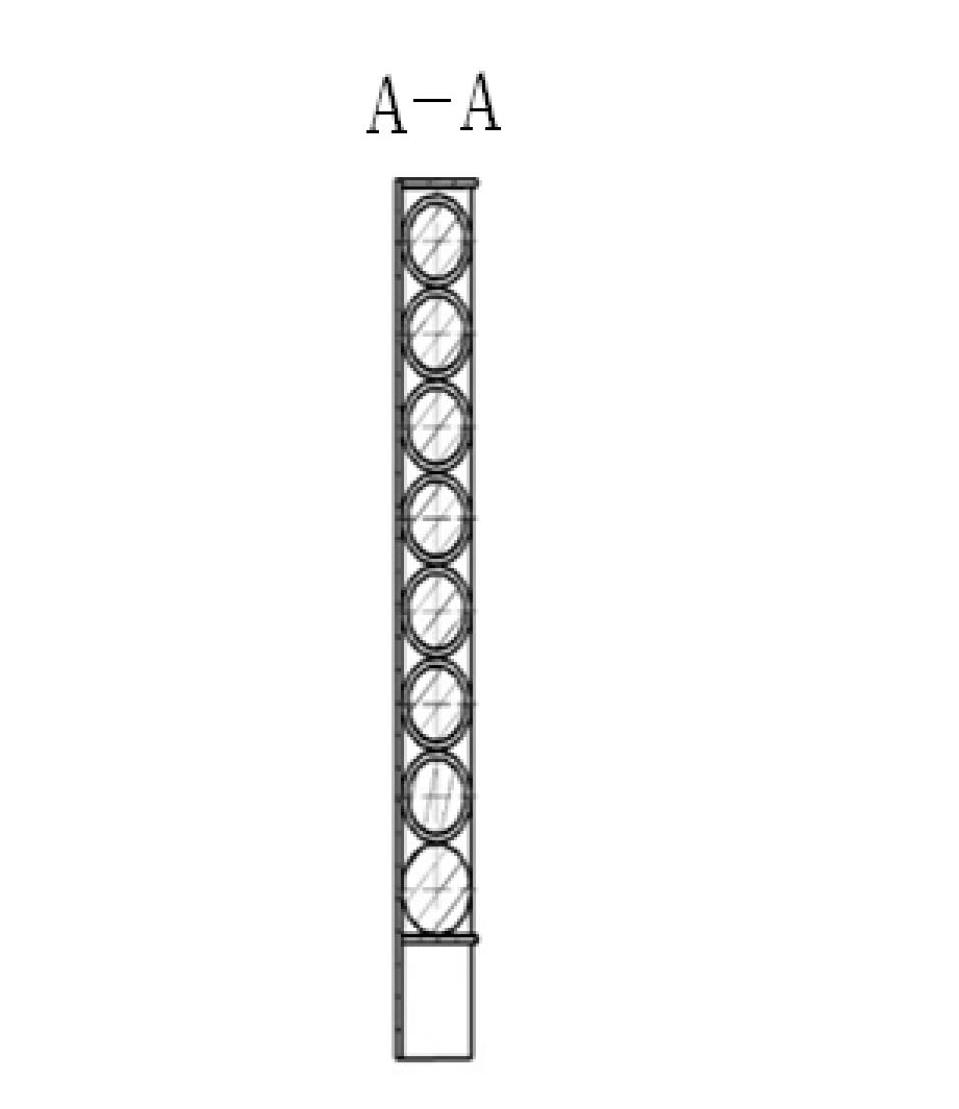

[0023] like Figure 1~Figure 2 As shown, a vibrating sieve for reducing missing product inserts includes a base 1, a vibrating plate 2, a vibrating groove 3, an adjusting rod 4, a cutout groove 5 and parts 6, and the vibrating groove 3 is equipped with a base 1. A vibrating plate 2 is installed on the base 1, the output end of the vibrating plate 2 is a slit groove 5, the two ends of the slit groove 5 are installed with an adjusting handle 4, and the component 6 is installed on the slit groove 5.

[0024] In the vibrating plate 2 , a spirally ascending track is installed along the inner wall of the vibrating plate 2 , and the exit of the track is the output end of the vibrating plate 2 .

[0025] The kerf groove 5 is a groove that rotates around its axis.

[0026] The two ends of the kerf groove 5 are provided with adjusting rods 4 by screws.

[0027] The distance between the said regulating poles 4 can be adjusted.

[0028] A vibrator is installed in the base 1, and when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com