Device for removing oil slick from turbid circulating water and recovering circulating water in aluminum processing industry

A technology of turbid circulating water and recovery device, which is applied in the direction of grease/oily substance/float removal device, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. , Isolate the problems of high water content of oil slick and incomplete separation of oil and water, and achieve the effect of good benefit prediction, simple facilities and water saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

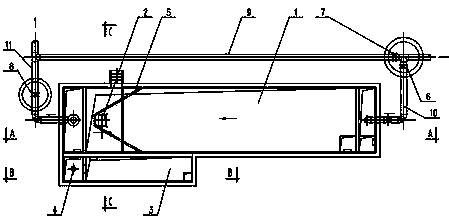

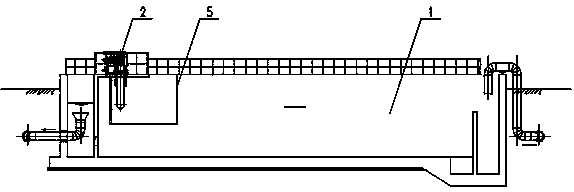

[0020] (1) Under normal working conditions, valve 7 is closed, valve 6 and valve 8 are opened, and the turbid circulating water passes through the grease trap 1 and then flows to the turbid circulating water return pool. An oil baffle plate 5 is set in the grease trap 1 to block the floating oil in the grease trap 1. The oil skimmer 2 selects an oil skimmer or an oil skimmer belt with a large or small oil skimming capacity, an oil skimmer or an oil skimmer belt according to the demand 2 is arranged on the top of the grease trap 1, and the oil skimmer or oil skimmer belt 2 works to collect floating oil into the oil collection tank 3.

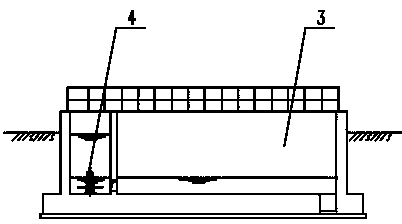

[0021] (2) A water seal is set at the bottom of the oil collecting tank 3, and the depth of the water seal is ≥500mm, and a submersible pump 4 is installed in one end of the oil collecting tank 3, and the other end of the oil collecting tank 3 is in the middle of the pool body where the submersible pump 4 is placed A partition wall is provided, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com