Double-modified starch fluid loss additive used for oil and gas field drilling fluid and preparation method thereof

A fluid loss reducer, oil and gas field technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of harsh modification conditions, molecular weight reduction, high temperature degradation, etc., to facilitate industrial production, reduce fluid loss Effects of improved performance and good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

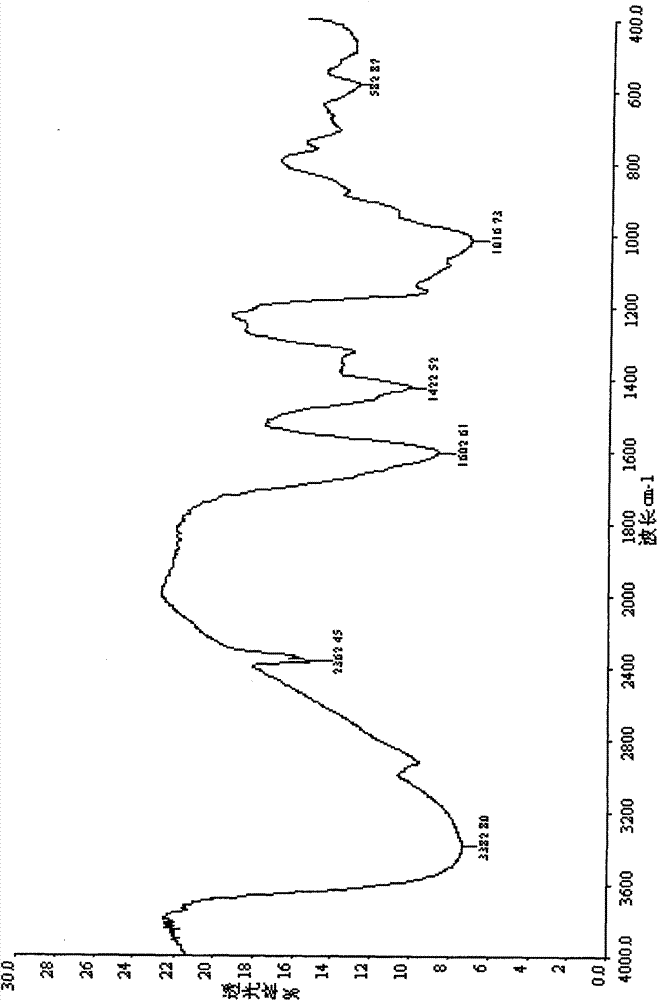

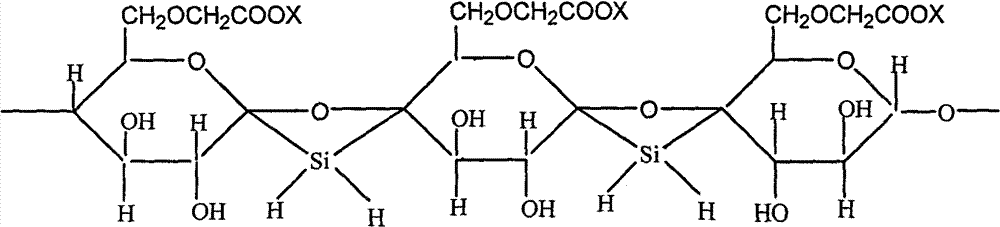

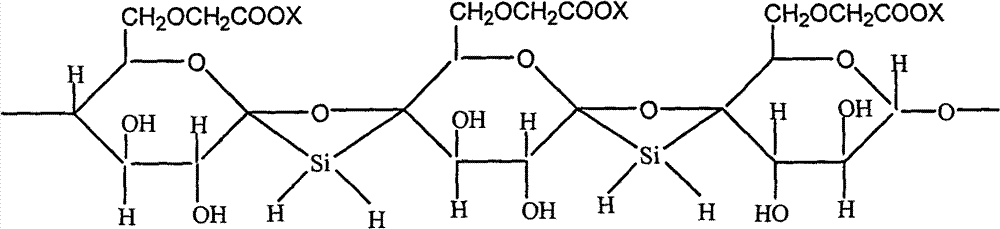

Image

Examples

Embodiment 1

[0050] Embodiment 1: the preparation of the first kind of starch fluid loss reducer

[0051] Add 8.1g of cornstarch and 0.243g of water-soluble sodium silicate into a three-necked flask, then add 36ml of isopropanol, install the three-necked flask in a constant temperature water bath at 40°C, and stir with a strong stirrer to make cornstarch and water-soluble silicic acid Sodium is evenly dispersed in isopropanol, 4.8g sodium hydroxide is mixed with sodium hydroxide solution with 10ml distilled water, drips the sodium hydroxide solution of volume fraction 40% ( about 20 minutes), after the sodium hydroxide solution was added dropwise, the first-stage reaction was carried out at normal pressure and 40°C under stirring, and the reaction time was 70 minutes;

[0052] After the first stage of reaction is completed, the temperature is raised to 50° C., and chloroacetic acid solution is added in a linear flow mode (the proportioning of chloroacetic acid and solvent isopropanol is: 5...

Embodiment 2

[0054] Embodiment 2: the preparation of the first kind of starch fluid loss reducer

[0055] Add 3.1g of potato starch, 5g of sweet potato starch and 0.162g of solid sodium silicate into a three-necked flask, then add 54ml of ethanol, install the three-necked flask in a 30°C constant temperature water bath, and stir with a strong stirrer to make potato starch, sweet potato starch, Solid sodium silicate is evenly dispersed in ethanol, 6.0g of sodium hydroxide is prepared into sodium hydroxide solution with 14ml of distilled water, and a 40% volume fraction of sodium hydroxide solution is dripped into a three-necked flask with a constant pressure dropping funnel under stirring (dropping finished in about 25 minutes), after the sodium hydroxide solution was added dropwise, the first-stage reaction was carried out at normal pressure and 30°C under stirring, and the reaction time was 100 minutes;

[0056] After the first stage of reaction is completed, the temperature is raised to ...

Embodiment 3

[0058] Embodiment 3: the preparation of the first kind of starch fluid loss reducer

[0059] Add 4.1g of wheat starch, 4g of rice starch and 0.405g of water-soluble potassium silicate into a three-necked flask, then add 81ml of ethanol, install the three-necked flask in a constant temperature water bath at 50°C, and stir with a strong stirrer to make the wheat starch and rice starch 1. Water-soluble potassium silicate is evenly dispersed in ethanol, and 10g of potassium hydroxide is prepared into potassium hydroxide solution with 18ml of distilled water, and the potassium hydroxide with a volume fraction of 40% is dripped into the three-necked flask with a constant pressure dropping funnel under stirring Solution (dropped in about 25 minutes), after the potassium hydroxide solution was added dropwise, the first stage reaction was carried out at normal pressure and 50°C under stirring, and the reaction time was 50 minutes;

[0060] After the first stage of reaction is completed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com