High-strength geocell

A geocell and powerful technology, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as engineering failure, molecular arrangement without orientation, weak nodes, etc., and achieve the effect of ensuring normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

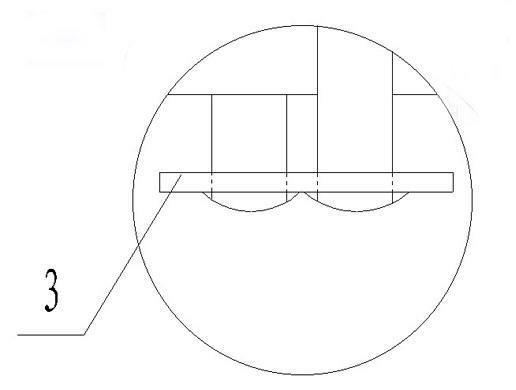

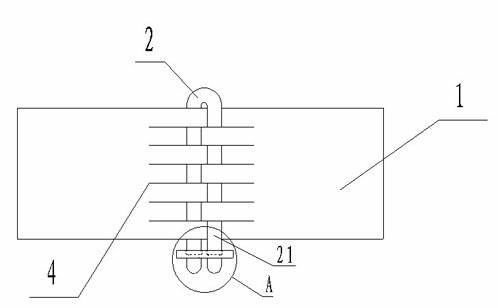

[0027] Such as figure 1 , figure 2 As shown, the present invention includes ribs 1 and U-shaped inserts 2, and the joints of adjacent ribs 1 are correspondingly provided with slits 4, and the free ends 21 of U-shaped inserts 2 are alternately passed through the two ribs successively. The slit weaves the two tendons into one, and the free end of the U-shaped insert 2 is connected with a closed lock 3 that prevents the insert from coming out.

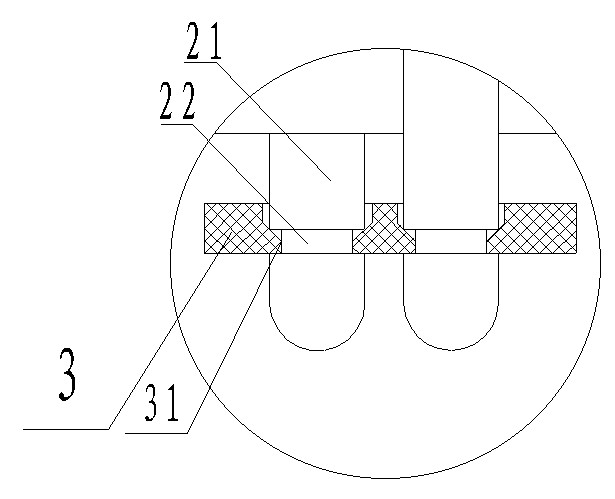

[0028] Such as image 3 , 4 As shown, the above-mentioned closure lock 3 is an elastic or flexible thin sheet, and the two free ends 21 of the corresponding U-shaped inserts of the thin sheet are provided with through holes 31. The diameter of the above-mentioned through holes 31 is slightly smaller than the diameter of the free ends 21 of the insert, 2 The free end 21 is radially provided with an annular locking groove 22, and the above-mentioned sheet is engaged in the annular locking groove 22 on the free end of the insert through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com