Railway vehicle window and assembly and disassembly method thereof

A rail vehicle and vehicle window technology, which is applied to window devices, window glass installation, windows/doors, etc., can solve the problem that it is not easy to control the flatness and smoothness of the external surface of the window and the vehicle body, the disassembly process is cumbersome, time-consuming and laborious, etc. problems, to achieve the effect of improving the fastening installation effect, simple process, and easy process accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

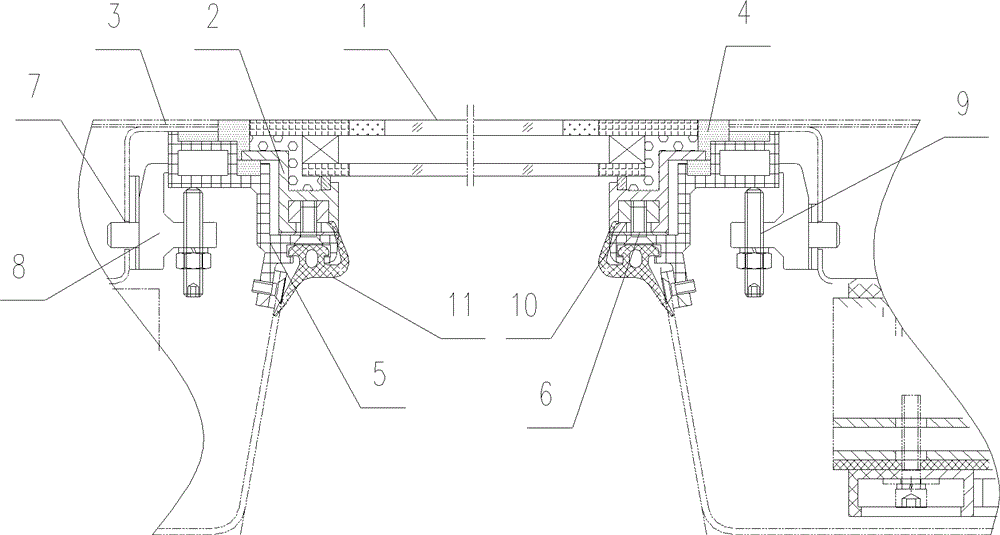

[0031] Such as figure 1 As shown, the rail vehicle window mainly includes:

[0032] Hollow glass 1 and window frame 2 pre-assembled into an integral structure, and then assembled with a fixed frame 5 to form an integral vehicle window, in

[0033] A sealant 4 is filled between the hollow glass 1 and the vehicle body 3 to realize sealing and fixing. specifically:

[0034] There are several positioning holes 7 on the inner side of the vehicle body 3, the fixed frame 5 is installed on the vehicle body 3 through the positioning pins 8 inserted into the positioning holes 7, and several fastening screws 9 pass through the positioning pins 8 and tighten the fixed frame 5 from the rear. .

[0035] A fixing groove 10 is arranged at the rear of the fixing frame 5, and several fixing screws 6 pass through the fixing groove 10 and tighten the window frame 2 from the rear.

[0036] A decorative strip 11 is nested in the fixing groove 10 .

[0037] On the basis of the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com